Cummins Engine Swap, trying to make PCM understand changes

#1

Well, many have said not to do this but we don't listen. The starting truck was a 2003 Dodge 1500 with a 5.9L and a 46RE trans. We have shoved a Cummins 12V and a 48RE trans in place. Engine mount is now complete, fuel system changed, driveshaft modified to fit. Now comes the fun part, wiring. The trans was easy, plugged right in. First things first, the wiring was pulled completely apart and tagged. We determined that the ASD relay is controlled by a crank and cam position signal. The ASD needed to flicker within 1.8 seconds. SO, we wired the crank sensor up, tied the cam sensor wire also, now the ASD senses signal and stays working when running and goes away when key is off. This means we have keyed starting and stopping on the 12ver shutdown plunger. (hooked onto the 12 volt power that is supplied from the ASD now that it is live) Keep in mind we placed the 360 oil pressure sender and water temp sender into the Cummins locations.

Ok, so now we have no tach reading. Or oil pressure, water temp and it is not charging.(360 alternator plugged in like stock) The dash is dead so to speak. Voltage reads, but no charge. Fuel gauge is correct. Now we started hooking items up to see where there is an open circuit. I also cut the harmonic balancer with 8 equal notches to send the correct signal to the crank sensor. (I know this is not healthy for the engine, it was a test, and not permanent) Plugged in the stock coil, IAC motor, MAP sensor, EVAP can, IAT sensor and leak detection pump. (<This item shows a generator source into the plug, thought it was the key.) We start the Cummins. WE HAVE TACH! Excited, we check other items. It is charging, oil pressure shows good, water temp reacts also. This seems like it is great. The coil is arcing like hell, but we will laugh if someone gets close enough. We start and shut it off a few times, test out well.

Now is where the problem persists. Since the tach worked the first time, and probably 6 starts after that, it is not working every time we start it now. We changed nothing around on wiring, all connections seem good. When the tach read, it seemed perfect. Dead on reading for the engine RPM's. Does anyone know what really drives this? This project is about perfection, and we will not have a cobbled up mess of a dash and a stand alone tach. I am certain that someone has knowledge of what I can do away with and fool the computer into thinking the 5.9 is still there. OR a DRB-III person that can modify the PCM. What do we do? Thanks in advance for taking the time to read all of this and your help.

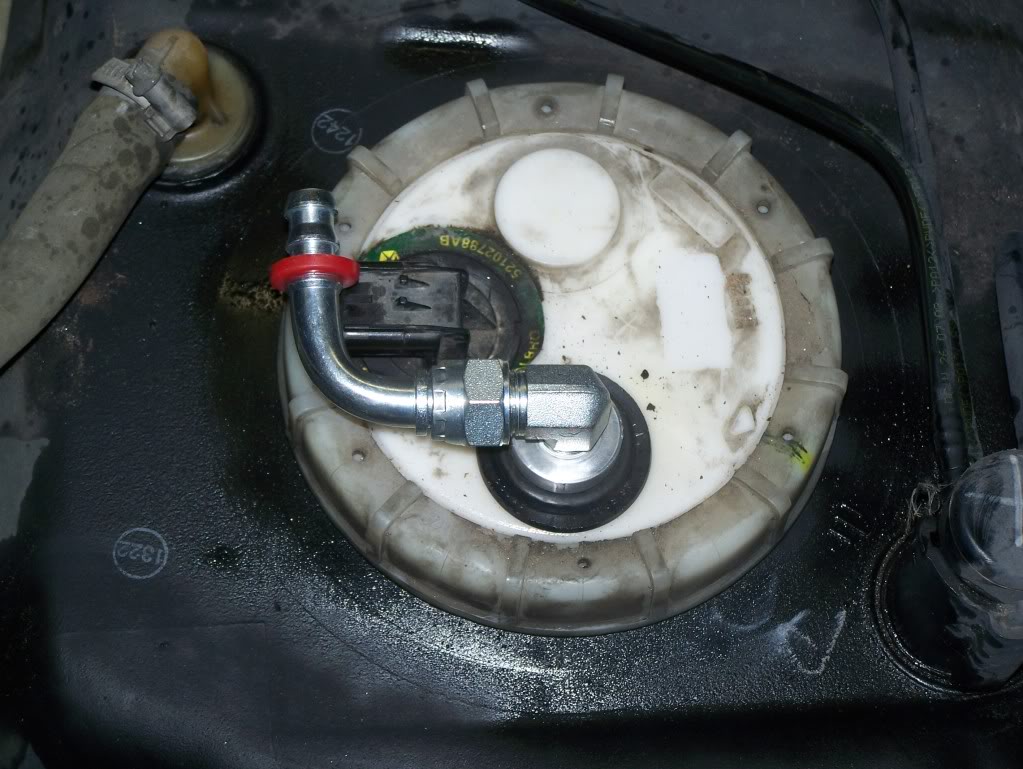

I will post pics if this site allows with no real post count, just to show you what we have. Thanks again, Chris

Ok, so now we have no tach reading. Or oil pressure, water temp and it is not charging.(360 alternator plugged in like stock) The dash is dead so to speak. Voltage reads, but no charge. Fuel gauge is correct. Now we started hooking items up to see where there is an open circuit. I also cut the harmonic balancer with 8 equal notches to send the correct signal to the crank sensor. (I know this is not healthy for the engine, it was a test, and not permanent) Plugged in the stock coil, IAC motor, MAP sensor, EVAP can, IAT sensor and leak detection pump. (<This item shows a generator source into the plug, thought it was the key.) We start the Cummins. WE HAVE TACH! Excited, we check other items. It is charging, oil pressure shows good, water temp reacts also. This seems like it is great. The coil is arcing like hell, but we will laugh if someone gets close enough. We start and shut it off a few times, test out well.

Now is where the problem persists. Since the tach worked the first time, and probably 6 starts after that, it is not working every time we start it now. We changed nothing around on wiring, all connections seem good. When the tach read, it seemed perfect. Dead on reading for the engine RPM's. Does anyone know what really drives this? This project is about perfection, and we will not have a cobbled up mess of a dash and a stand alone tach. I am certain that someone has knowledge of what I can do away with and fool the computer into thinking the 5.9 is still there. OR a DRB-III person that can modify the PCM. What do we do? Thanks in advance for taking the time to read all of this and your help.

I will post pics if this site allows with no real post count, just to show you what we have. Thanks again, Chris

Last edited by Altair; 02-01-2010 at 10:24 PM. Reason: Changing thread title at request of OP

#3

The following users liked this post:

RPMRamFury (04-13-2022)

#5

#7

Trending Topics

#9

The engine is mechanical. A throttle position sensor and crank sensor are all you really have. No cam sensor, I have it being triggered by the crank sensor to keep the ASD on. Basically I am trying to get the dash functional and let the trans work correctly.

#10

http://www.competitiondiesel.com/for...ad.php?t=76731