1998 Dodge B3500 Van Oil Pump Replacement

#1

While driving my 1998 Dodge B3500 Van Wagon, I was experiencing the oil pressure dropping to 0 problem that is common in Dodge 5.2 liter engines. This problem has several manifestations but the root of the problem is sludge buildup in the engine oiling system.

In the service manuals, removing the oil pan involves several steps that, for the most part, work just fine. Unfortunately, on the B3500 and similar full size vans, access to the oil pan is restricted by the front crossmember and the pan cannot be removed even if the engine is unbolted from the mounts and lifted. This comment adds a few steps to the procedure given in the manuals to assist with removing the oil pan on these vehicles.

Here's the location of the pan:

The solution is to lower the front crossmember a few inches in addition to lifting the engine a few inches. The crossmember is held in by 8 bolts, 4 to a side. Mine were locked in place by rust inside the frame rail but came out with repeated applications of PB Blaster inside the frame rail and judicious application of a breaker bar and/or impact wrench.

I used a floor jack to lift the engine one side at a time as far as possible after removing the two nuts on the motor mounts. Then I propped it in place with 2x2s braced with angle iron as seen in the next photo. I also used a floor jack under the transmission for additional support.

As you might notice at the left side of the above photo, I was finally able to wriggle out the oil pan between the crossmember and transmission bellhousing after lifting the engine and lowering the crossmember.

This photo shows the crossmember on its way down. I used a transmission jack under the center portion to lower it, thus gaining an additional few inches of access. After lowering the crossmember as far as the suspension allows, I just let it dangle in place while I removed the oil pan. Or, if you prefer, you can install longer bolts to hold it in the lowered position.

Next is a photo showing what my oil pump looked like. Note the accumulation of blackened sludge on the pickup screen. This, along with floating bits of caramelized sludge in the oil is what causes the oil pressure to drop after the engine warms up.

As an aside, when I removed the second of the two bolts holding the oil pump in place, it was coated in a tar-like substance that stunk up the garage. It smelled like something had died and composted in there.

The following photo shows a small portion of the detritus that was trapped in the bottom of my oil pan. Note the metal shards mixed in with the hardened clumps of blackened oil sludge. The metal pieces were non-magnetic and fairly soft, possibly aluminum and possibly from a bearing. The lower sump portion of the oil pan was filled with a thick goo of the black crud. Only a tiny bit of this crud is shown in this photo. There was much, much more, and you'll learn why as you keep reading.

The next photo shows the interior of the oil pan after I dumped the remaining oil into the large cat litter bucket pictured above. The design of the Dodge oil pan drain plug (center of photo) causes the last half-pint or so of oil to be trapped instead of ejected during oil changes. This is due to the plug bolt being welded inside the oil pan, creating a 9/16th inch high obstruction that holds particulate matter in place along with several ounces of dirty oil. You will never completely drain your dirty oil with the pan in place.

Note also the internal windage tray in the above photo. It is the slotted area in the bottom 1/3rd of the picture. Much to my chagrin, I discovered after removing the pan that the common Melling oil pickup tube sold by parts stores as fitting this engine does not fit this engine. The original equipment (OE) tube has a unique and longer tube design that fits into the slot in the windage tray. Here is a photo of the two pickup tubes side by side. If you want to replace the pickup tube, you must acquire the correct factory-fit version. I ended up just cleaning the screen on mine and reusing it. The OE tube is at the bottom.

This photo shows how the OE oil pickup tube matches the slotted area in the windage tray inside the oil pan. Note that this also makes it trickier to get the pan off. It also makes it harder to get it on the engine, as you must by feel guide the tube into the slot while holding the gasket in place and raising the pan and inserting pan bolts.

After installing a new rear main seal, new oil pump, the original pickup tube, and a new pan gasket, I bolted the pan in place, raised and attached the crossmember, and lowered and reattached the engine. I'd like to say that all my problems were solved and I lived happily ever after but that would be a lie. The problem is much reduced and I can now drive the van for distances unimaginable before this operation. Twenty miles!! But since doing this work, I have had one instance where the oil pressure dropped to 0 and there is a knocking sound when the engine starts up first thing in the morning that goes away after one or two seconds. I believe I may have a damaged cam bearing but that will have to wait for another repair session as it is a huge job.

Update [3-5-2018]: The work I describe in this post mostly fixed the problem but there must have still been some restriction in internal oil passages. Treating with a quart of Marvel Mystery Oil as part of a fresh oil and filter change, then driving 500 or so miles with the mystery oil in followed by another oil and filter change completely solved the oil problems and the engine operated normally for the remainder of the time I owned the vehicle.

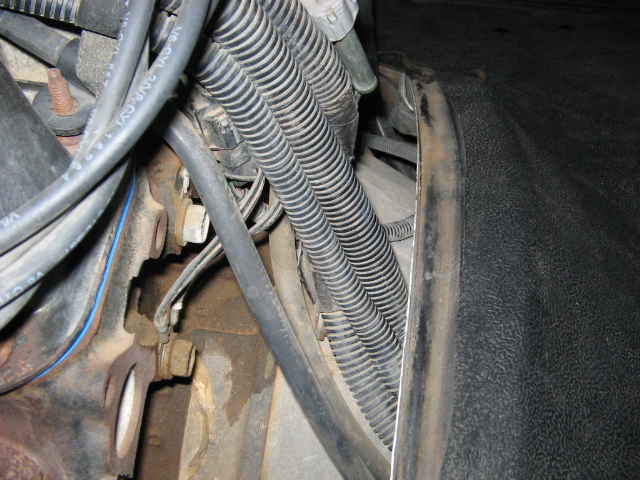

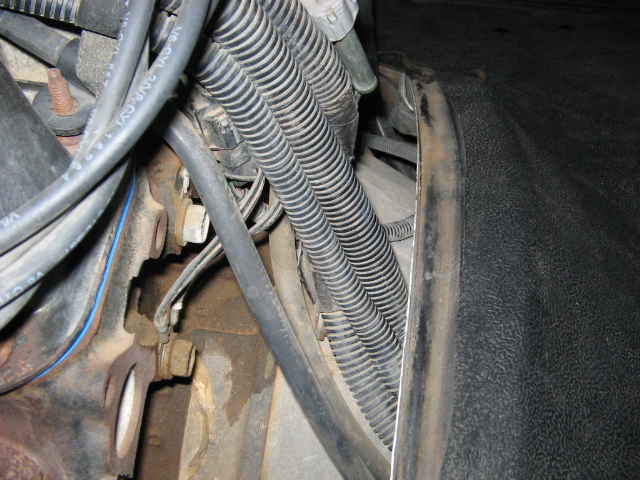

I did not drop the exhaust system and it contacted one of the strut mounts, which limited how high I could raise the engine. But even if I had dropped the exhaust, you'll see in the following two photos that other obstructions also exist. The wiring harnesses in the first photo were crackling menacingly against the floor pan on the left and the transmission filler tube in the second photo was smushed against the floor pan on the right. If you drop the exhaust and remove the trans filler, you may be able to get another inch or so lift on the engine but it is probably not enough to remove the oil pan without also dropping the crossmember and getting the extra three or four inches of clearance that provides.

In the service manuals, removing the oil pan involves several steps that, for the most part, work just fine. Unfortunately, on the B3500 and similar full size vans, access to the oil pan is restricted by the front crossmember and the pan cannot be removed even if the engine is unbolted from the mounts and lifted. This comment adds a few steps to the procedure given in the manuals to assist with removing the oil pan on these vehicles.

Here's the location of the pan:

The solution is to lower the front crossmember a few inches in addition to lifting the engine a few inches. The crossmember is held in by 8 bolts, 4 to a side. Mine were locked in place by rust inside the frame rail but came out with repeated applications of PB Blaster inside the frame rail and judicious application of a breaker bar and/or impact wrench.

I used a floor jack to lift the engine one side at a time as far as possible after removing the two nuts on the motor mounts. Then I propped it in place with 2x2s braced with angle iron as seen in the next photo. I also used a floor jack under the transmission for additional support.

As you might notice at the left side of the above photo, I was finally able to wriggle out the oil pan between the crossmember and transmission bellhousing after lifting the engine and lowering the crossmember.

This photo shows the crossmember on its way down. I used a transmission jack under the center portion to lower it, thus gaining an additional few inches of access. After lowering the crossmember as far as the suspension allows, I just let it dangle in place while I removed the oil pan. Or, if you prefer, you can install longer bolts to hold it in the lowered position.

Next is a photo showing what my oil pump looked like. Note the accumulation of blackened sludge on the pickup screen. This, along with floating bits of caramelized sludge in the oil is what causes the oil pressure to drop after the engine warms up.

As an aside, when I removed the second of the two bolts holding the oil pump in place, it was coated in a tar-like substance that stunk up the garage. It smelled like something had died and composted in there.

The following photo shows a small portion of the detritus that was trapped in the bottom of my oil pan. Note the metal shards mixed in with the hardened clumps of blackened oil sludge. The metal pieces were non-magnetic and fairly soft, possibly aluminum and possibly from a bearing. The lower sump portion of the oil pan was filled with a thick goo of the black crud. Only a tiny bit of this crud is shown in this photo. There was much, much more, and you'll learn why as you keep reading.

The next photo shows the interior of the oil pan after I dumped the remaining oil into the large cat litter bucket pictured above. The design of the Dodge oil pan drain plug (center of photo) causes the last half-pint or so of oil to be trapped instead of ejected during oil changes. This is due to the plug bolt being welded inside the oil pan, creating a 9/16th inch high obstruction that holds particulate matter in place along with several ounces of dirty oil. You will never completely drain your dirty oil with the pan in place.

Note also the internal windage tray in the above photo. It is the slotted area in the bottom 1/3rd of the picture. Much to my chagrin, I discovered after removing the pan that the common Melling oil pickup tube sold by parts stores as fitting this engine does not fit this engine. The original equipment (OE) tube has a unique and longer tube design that fits into the slot in the windage tray. Here is a photo of the two pickup tubes side by side. If you want to replace the pickup tube, you must acquire the correct factory-fit version. I ended up just cleaning the screen on mine and reusing it. The OE tube is at the bottom.

This photo shows how the OE oil pickup tube matches the slotted area in the windage tray inside the oil pan. Note that this also makes it trickier to get the pan off. It also makes it harder to get it on the engine, as you must by feel guide the tube into the slot while holding the gasket in place and raising the pan and inserting pan bolts.

After installing a new rear main seal, new oil pump, the original pickup tube, and a new pan gasket, I bolted the pan in place, raised and attached the crossmember, and lowered and reattached the engine. I'd like to say that all my problems were solved and I lived happily ever after but that would be a lie. The problem is much reduced and I can now drive the van for distances unimaginable before this operation. Twenty miles!! But since doing this work, I have had one instance where the oil pressure dropped to 0 and there is a knocking sound when the engine starts up first thing in the morning that goes away after one or two seconds. I believe I may have a damaged cam bearing but that will have to wait for another repair session as it is a huge job.

Update [3-5-2018]: The work I describe in this post mostly fixed the problem but there must have still been some restriction in internal oil passages. Treating with a quart of Marvel Mystery Oil as part of a fresh oil and filter change, then driving 500 or so miles with the mystery oil in followed by another oil and filter change completely solved the oil problems and the engine operated normally for the remainder of the time I owned the vehicle.

I did not drop the exhaust system and it contacted one of the strut mounts, which limited how high I could raise the engine. But even if I had dropped the exhaust, you'll see in the following two photos that other obstructions also exist. The wiring harnesses in the first photo were crackling menacingly against the floor pan on the left and the transmission filler tube in the second photo was smushed against the floor pan on the right. If you drop the exhaust and remove the trans filler, you may be able to get another inch or so lift on the engine but it is probably not enough to remove the oil pan without also dropping the crossmember and getting the extra three or four inches of clearance that provides.

Last edited by edgadz1955; 03-05-2018 at 12:03 PM.

#2

SWEET write up. It's bookmarked because it's rare to get a SITCKY here.

Usually, I run the Gunk Motor Flush every other oil change. The van front wheels are up on metal vehicle ramps allowing the oil and sludge to flow out the drain plug. Got to love gravity. The day when this no longer works, I'll follow your write up here.

Usually, I run the Gunk Motor Flush every other oil change. The van front wheels are up on metal vehicle ramps allowing the oil and sludge to flow out the drain plug. Got to love gravity. The day when this no longer works, I'll follow your write up here.

#3

318s are known sludge monsters I have owned 8 and still have one on a engine stand but never changed a oil pump in any other than the rebuild on the stand. By the way I was able too change the oil pan gasket by jacking one side of the motor in a 87 B150.

Also Edgadz1955 your van is amazingly clean underneath.

Also Edgadz1955 your van is amazingly clean underneath.

#4

edgadz1955

great write up... noticed one broken photo link

stev a question...

If after 175,000 mi in the 5.2, would it be a good idea to run Gunk Flush through? Been using full synthetic oil for the last 50,000 miles since I bought it used. I drive this van only long distances on the highway, but will do anything preventive that I can to keep it on the road without a problem. Will use your ramp technique next time I change oil.

Appreciate any advice

great write up... noticed one broken photo link

stev a question...

If after 175,000 mi in the 5.2, would it be a good idea to run Gunk Flush through? Been using full synthetic oil for the last 50,000 miles since I bought it used. I drive this van only long distances on the highway, but will do anything preventive that I can to keep it on the road without a problem. Will use your ramp technique next time I change oil.

Appreciate any advice

#5

Some aftermarket oil pans for these engines use a small triangular piece of threaded metal to hold the drain plug. This should help with evacuation. Some owner have removed the bolt from inside the pan and welded it to the outside. This lets all of the oil drain.

I bought some dental saliva ejectors (the tubes dentists hang in your mouth to extract your spit while working on you). They are plastic tubes with a wire inside that can be bent into shapes. I'm going to try bending a 180 curve into one, feeding it into the drain hole, and then using a vacuum evacuator to see if it will pull the last bit of sludgy oil the next time I do an oil change.

#6

Oil pumps can easily last 200K miles. The oil pump in my van was still good but I figured I might as well spend the $20 and change it while I was in there. Although, to be honest, I'm not sure how smart pre-emptively replacing factory parts on older vehicles is when you consider the poor quality of modern Chinese-made replacements.

The factory oil pickup tube has a screen with tighter mesh than the aftermarket version. This reduces the amount of garbage that can be pulled into the pump, which is good, but causes the screen to clog up faster, which is bad. There are tradeoffs in everything.

#7

Wonder why the magnums are sludge prone when the LA series are not, to my knowledge.

I think my oil pan itself is threaded, and the area where the drain plug goes is a bit lower.

I watched my engine tear down when rebuilt at 172k miles. Was carboned but no sludge. If not for a cracked head and bad valve stem seals, it likely could have gone a lot lot longer with a new head and seals, but I was unaware.

I know there are oil extractor kits that remove oil through the dipstick hole, popular for boats where you can't get under the engine for gravity to do its thing.

I think my oil pan itself is threaded, and the area where the drain plug goes is a bit lower.

I watched my engine tear down when rebuilt at 172k miles. Was carboned but no sludge. If not for a cracked head and bad valve stem seals, it likely could have gone a lot lot longer with a new head and seals, but I was unaware.

I know there are oil extractor kits that remove oil through the dipstick hole, popular for boats where you can't get under the engine for gravity to do its thing.

Trending Topics

#9

edgadz1955

great write up... noticed one broken photo link

stev a question...

If after 175,000 mi in the 5.2, would it be a good idea to run Gunk Flush through? Been using full synthetic oil for the last 50,000 miles since I bought it used. I drive this van only long distances on the highway, but will do anything preventive that I can to keep it on the road without a problem. Will use your ramp technique next time I change oil.

Appreciate any advice

great write up... noticed one broken photo link

stev a question...

If after 175,000 mi in the 5.2, would it be a good idea to run Gunk Flush through? Been using full synthetic oil for the last 50,000 miles since I bought it used. I drive this van only long distances on the highway, but will do anything preventive that I can to keep it on the road without a problem. Will use your ramp technique next time I change oil.

Appreciate any advice