2000 2.5 V6 6G73 Oil pressure/ valve lash/ low temp

#81

Oil pressure is getting worse. Now the light comes on before it even gets up to operating temperature. It looks like doing the head gaskets(my suspected point of oil leak) is going to run about $150 for parts and I would possibly have the heads crack tested if I don't find any obvious failure in the head gasket(s). I'm really not a fan of taking the timing belt off again but I made some good progress as far as fabricating a tool to set the belt tension, so that helps a lot. I'll see what happens over winter and go from there.

Going to have a kid turning 16 in a year so there's no point in buying something nice when this car has held on until now.

It's definitely made me think as far as how long an engine can run on low oil pressure.

Going to have a kid turning 16 in a year so there's no point in buying something nice when this car has held on until now.

It's definitely made me think as far as how long an engine can run on low oil pressure.

#82

Started the car up this morning when it was about -3* F. Now the light is on until over 3000rpm. So... parts are on order. It's going under the knife as soon as possible. Probably not going to be the best job but it's either that or the car goes in for scrap when it dies. I can't see running at 3000rpm under 4psi oil pressure as a good thing or something that will run much longer.

Wish me luck.

Wish me luck.

#83

Started the car up this morning when it was about -3* F. Now the light is on until over 3000rpm. So... parts are on order. It's going under the knife as soon as possible. Probably not going to be the best job but it's either that or the car goes in for scrap when it dies. I can't see running at 3000rpm under 4psi oil pressure as a good thing or something that will run much longer.

Wish me luck.

Wish me luck.

Ours is still tickling the flickering light at times. But the bigger problem is the fault in the instrument cluster that causes it all to go dead, including the wipers and power door locks. Everything else works, just not those items..

#84

Nope, pump was pulled and all clearances were within spec. So, I'm doing head gaskets. That's the only other place I can think of that would be allowing such a large amount of pressure loss. The pan was clean when I pulled it and the pickup had a small amount of varnish but went down to bare metal with a spray of brake cleaner. So, no sludge monster there. I added a washer into the pressure relief valve in the oil pump so it should run at a higher operating pressure.

So far nothing has solved the problem and that's led me to either head gasket(s) or a crack in the block or heads somewhere in the oil galleys. I'd be 99.99% confident in a blowout in one or both of the head gaskets because it appears that the supply and return run right next to each other in the head gasket. I will not know for sure until I pull it apart. I know the cooling system is operating well and I have never seen the gauge creep up even before the problem started so I can probably rule out that. There is no coolant loss or oil loss so that would also avoid a crack or large warp to the heads. If there is nothing obvious with the head gaskets I'll probably have to take them into a machine shop to be checked.

I'm interested to see how the cam bearings look since the car is being driven once a day with essentially no oil pressure except the first couple minutes after startup. If it makes it through that abuse I'll have to raise my level of confidence in this engine even more. Might even send Mitsubishi a Thank You out of the whole deal. It's not their fault but still a testament to engineering that it can hold up under such conditions.

So far nothing has solved the problem and that's led me to either head gasket(s) or a crack in the block or heads somewhere in the oil galleys. I'd be 99.99% confident in a blowout in one or both of the head gaskets because it appears that the supply and return run right next to each other in the head gasket. I will not know for sure until I pull it apart. I know the cooling system is operating well and I have never seen the gauge creep up even before the problem started so I can probably rule out that. There is no coolant loss or oil loss so that would also avoid a crack or large warp to the heads. If there is nothing obvious with the head gaskets I'll probably have to take them into a machine shop to be checked.

I'm interested to see how the cam bearings look since the car is being driven once a day with essentially no oil pressure except the first couple minutes after startup. If it makes it through that abuse I'll have to raise my level of confidence in this engine even more. Might even send Mitsubishi a Thank You out of the whole deal. It's not their fault but still a testament to engineering that it can hold up under such conditions.

Last edited by TZFBird; 01-27-2016 at 03:50 PM.

#85

#86

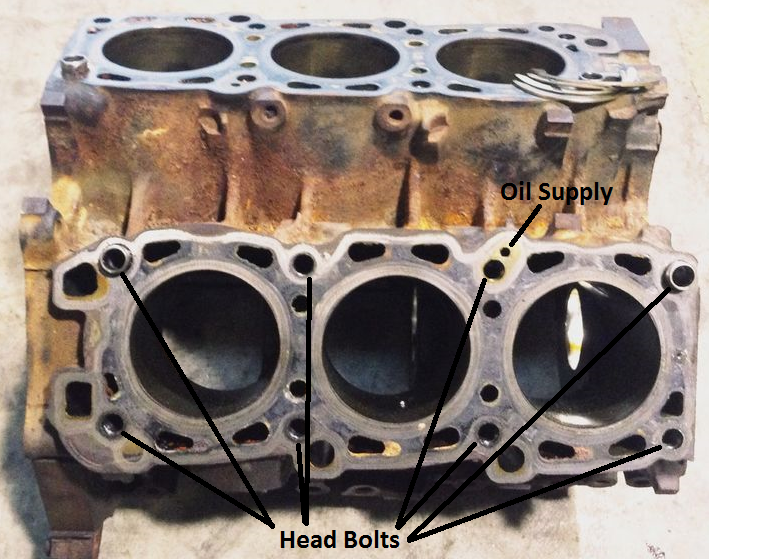

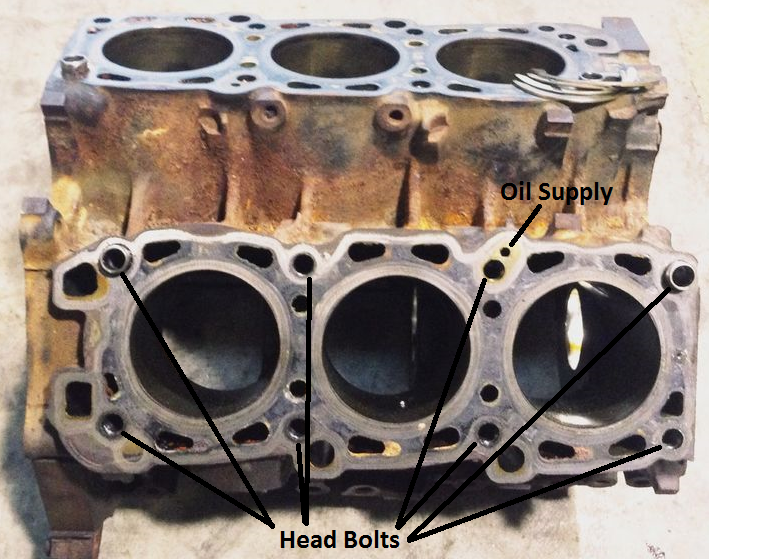

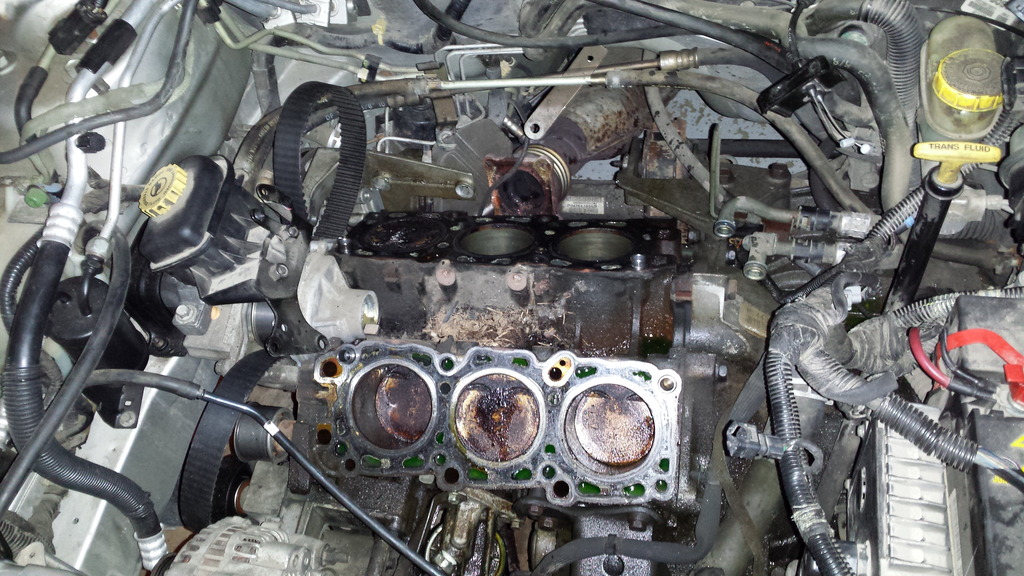

Front cylinder head is pulled. The oil returns from the head do not run next to the supply galley.

Instead there are two on the middle of the head at the bottom(2 large unlabeled holes) as well as another 2 on the left in the picture. They seem to be more for air circulation to prevent building pressure in the crankcase. Overall a very well designed engine IMO, but I'm no engineer so I can't say one way or another.

The supply runs up near the valley in the block between cylinders 4&6 for the front and between 3&5 for the rear. In the head it splits in order to feed each rocker arm shaft. Where the oil passes from the block to the head, there is a head bolt that runs next to the galley. In the head gasket these two holes are combined into one. Essentially a washer between the cylinder head and the bolt is what keeps oil pressure up in the system. Not sure why they did that exactly. So, it depends on what I see when the rear head is removed.

I got pictures and will get them posted one of these days. Overall it's not that bad since I got most of the rusty exhaust bolts fixed last time I worked on things. It will be real nice to figure out the root cause of the oil problem but besides the head bolt the oil can only go into the cooling system, combustion chamber or into the engine valley. Since there is no oil loss I can only assume it is pushing past the head bolt, but that's TBD.

Also note the mouse nest that was in under the lower intake manifold.

Instead there are two on the middle of the head at the bottom(2 large unlabeled holes) as well as another 2 on the left in the picture. They seem to be more for air circulation to prevent building pressure in the crankcase. Overall a very well designed engine IMO, but I'm no engineer so I can't say one way or another.

The supply runs up near the valley in the block between cylinders 4&6 for the front and between 3&5 for the rear. In the head it splits in order to feed each rocker arm shaft. Where the oil passes from the block to the head, there is a head bolt that runs next to the galley. In the head gasket these two holes are combined into one. Essentially a washer between the cylinder head and the bolt is what keeps oil pressure up in the system. Not sure why they did that exactly. So, it depends on what I see when the rear head is removed.

I got pictures and will get them posted one of these days. Overall it's not that bad since I got most of the rusty exhaust bolts fixed last time I worked on things. It will be real nice to figure out the root cause of the oil problem but besides the head bolt the oil can only go into the cooling system, combustion chamber or into the engine valley. Since there is no oil loss I can only assume it is pushing past the head bolt, but that's TBD.

Also note the mouse nest that was in under the lower intake manifold.

Last edited by TZFBird; 02-16-2016 at 12:00 PM.

#87

Stopped by the local Mitsubishi dealer and they had even less information for me than the Dodge dealer. Can't blame them since they don't stand to make any money off it and it's not even in their brand of vehicle. All I found out is what I know, they don't use sealant on the head bolts to help retain oil pressure.

Last couple days have been worthless. If anyone has to change out a power steering pressure line on one of these, I feel sorry for them. After an hour I have yet to get the bracket bolts off the rear cylinder head. Also one manifold bolt is rusted on so I'll probably be cutting that off tonight. Joy, another hack-job on this car. To raise morale I fabricated a new timing belt tensioner tool today. This one is a lot better than the previous model. If anyone cares, here's what I made it out of and a few of the critical dimensions. I'm either fortunate enough or dumb enough to work mechanical maintenance, so just about everything I need to build tools can be found in the trash can. It uses a 1" long piece of 3/8" keystock, 6" of 1"x 3/16" steel flatstock, and two 1/8" x 3/4" roll pins. Pretty much all you need to know is that the pins are in 3/16" from the end of the flatstock to the center of the pins. Then the two pins are centered in the 1" steel with a hole spacing of 0.547". Using a mill made setting that easy but if you have any experience with metal working you should be able to figure out how to do it with just a drill. I welded the key to the bottom side of the flatstock to make it thicker. The problem I ran into before was that the pins would bend way before I got close to setting the tension on the eccentric bearing. So the keystock makes the effective length of the pins shorter thus increasing the side-load that the pins will take before distortion.

I'm still working on getting pics up so it should help explain all that a lot better. Apparently a lot of Mitsubishi engines use this sort of tensioning system because everyone I have talked to said they have had to make something similar when working on a Mitsubishi.

Last couple days have been worthless. If anyone has to change out a power steering pressure line on one of these, I feel sorry for them. After an hour I have yet to get the bracket bolts off the rear cylinder head. Also one manifold bolt is rusted on so I'll probably be cutting that off tonight. Joy, another hack-job on this car. To raise morale I fabricated a new timing belt tensioner tool today. This one is a lot better than the previous model. If anyone cares, here's what I made it out of and a few of the critical dimensions. I'm either fortunate enough or dumb enough to work mechanical maintenance, so just about everything I need to build tools can be found in the trash can. It uses a 1" long piece of 3/8" keystock, 6" of 1"x 3/16" steel flatstock, and two 1/8" x 3/4" roll pins. Pretty much all you need to know is that the pins are in 3/16" from the end of the flatstock to the center of the pins. Then the two pins are centered in the 1" steel with a hole spacing of 0.547". Using a mill made setting that easy but if you have any experience with metal working you should be able to figure out how to do it with just a drill. I welded the key to the bottom side of the flatstock to make it thicker. The problem I ran into before was that the pins would bend way before I got close to setting the tension on the eccentric bearing. So the keystock makes the effective length of the pins shorter thus increasing the side-load that the pins will take before distortion.

I'm still working on getting pics up so it should help explain all that a lot better. Apparently a lot of Mitsubishi engines use this sort of tensioning system because everyone I have talked to said they have had to make something similar when working on a Mitsubishi.

Last edited by TZFBird; 02-10-2016 at 02:26 PM.

#88

As anyone reading this can tell, I'm overly excited to work on this car. Finally down to the PS pump bracket that is keeping the rear head from being removed.

** If anyone is going to do head gaskets on this car, save yourself the trouble and just drop the engine. Otherwise it's a real treat. I'm starting to think this car should have just ended up getting parted out instead. But, it is what it is and I'm in to deep at this point. Fingers crossed that the rear head is out by the end of the weekend.

I'm still debating between just putting it back together or taking the heads in to be checked out. I don't want to spend any more than I have to on this and so far I'm on good terms with a local machine shop, which has saved me quite a bit in the past.

An inspection of the valve train will be the deciding point though.

** If anyone is going to do head gaskets on this car, save yourself the trouble and just drop the engine. Otherwise it's a real treat. I'm starting to think this car should have just ended up getting parted out instead. But, it is what it is and I'm in to deep at this point. Fingers crossed that the rear head is out by the end of the weekend.

I'm still debating between just putting it back together or taking the heads in to be checked out. I don't want to spend any more than I have to on this and so far I'm on good terms with a local machine shop, which has saved me quite a bit in the past.

An inspection of the valve train will be the deciding point though.

#89

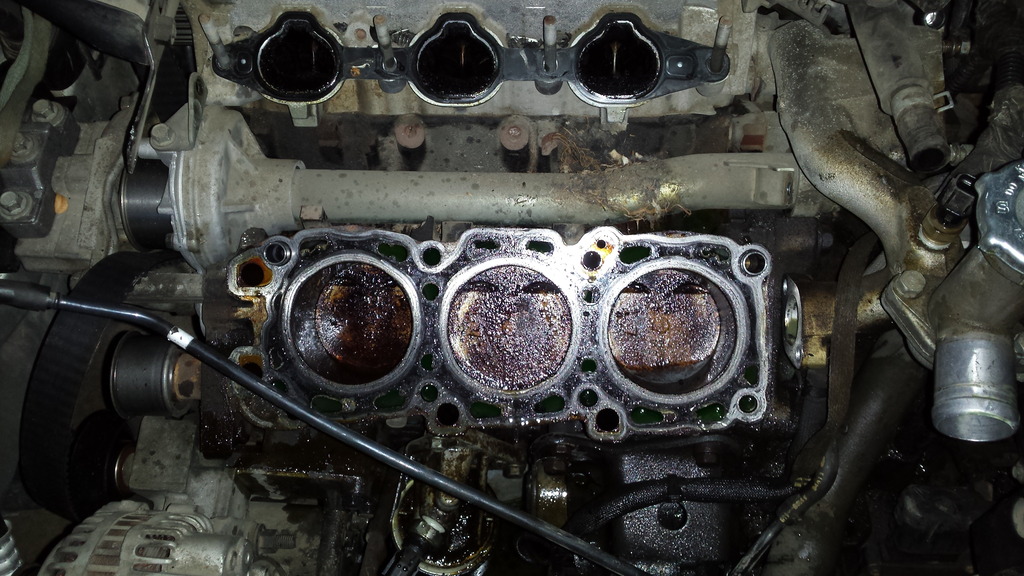

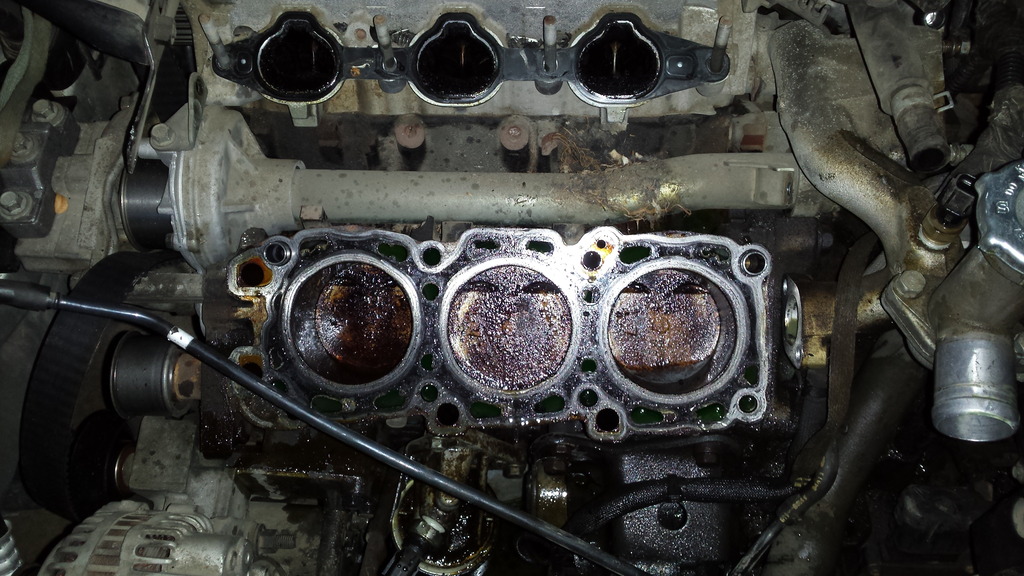

Engine finally torn down. I could have got away with putting it back together but put a few small scratches right in the sealing surface around cylinder #1. So, there's a chance the heads will be going into the shop for that anyway... grrr.

All cylinders and intake runners are full of carbon buildup and it's so bad in some of the cylinders that it's flaking off(#4?? left rear). FYI we run Sam's Club gas and I asked where they get their fuel from and never got a good answer. I'm also fighting carbon in another vehicle so I can only assume the misfire codes are because of the carbon. That part is explained at least. Needless to say I'm going either start running fuel from a name brand chain, or else start running a fuel system treatment to offset the lack of cleaners in the fuel.

I have not torn down the heads to look for a path of oil pressure loss so that's tomorrow's project.

Don't bother working on these cars if you don't have small hands/arms, otherwise enjoy being in a constant state of anger. I can only hope that a problem is found, or else this whole project was completely pointless.

Last edited by TZFBird; 02-16-2016 at 12:02 PM.

#90

I have both cylinder heads on and all the Power Steering stuff back on. That all took up most of the weekend but at least it's all easy from here on out. I still have no definite idea of what the low oil pressure is caused by. After this I am throwing in the towel on this car. As soon as this one is back on the road we are going to start test-driving to start the process for finding something different. I can't say we will find something better because this car has never left us stranded even though it has all sorts of issues.

Just counting down the days until I can say 'bye' to this site.

Thanks for the help to all who have posted so far.

If anyone has any thoughts, suggestions, or questions I'm open now but once the last bolt is tight, I'm washing my hands of this thing. I've lost enough sleep over it.

Just counting down the days until I can say 'bye' to this site.

Thanks for the help to all who have posted so far.

If anyone has any thoughts, suggestions, or questions I'm open now but once the last bolt is tight, I'm washing my hands of this thing. I've lost enough sleep over it.