Rear Main Seal

#11

Join Date: Aug 2014

Location: Bohners Lake, Wisconsin

Posts: 64

Received 0 Likes

on

0 Posts

Thanks for your advise. Could you explain a little more how you offset the split? I linked the seal that I ordered for this engine and I dont see how it could be off set.

http://www.ebay.com/itm/Fel-Pro-BS40...RVygJD&vxp=mtr

#13

If you want something slick to do this with, 93_ragtop , there's a tool known as a Sneaky Pete designed to help slip rope seals out and in.

Here's a Youtube of it being done:

And here's an Amazon listing for the tool:

PM me - I had bought one, but then my mechanic offered to do it while he had the motor out doing the freeze plugs, and I jumped at that offer *grins*

RwP

Here's a Youtube of it being done:

And here's an Amazon listing for the tool:

PM me - I had bought one, but then my mechanic offered to do it while he had the motor out doing the freeze plugs, and I jumped at that offer *grins*

RwP

#14

#15

"when the mechanic had my engine out...." yikes. I am my own mechanic, nobody touches my truck but me, only exception is stuff like an alignment, something I did for years for a living but don't have access to my own unit.... and at that, I am standing "right there" telling the guy doing it exactly where I want it set.....

whether a rope or a neoprene, ALL of these engines (3.9, 318, 360) are a 2 pc.seal.

Dont know about 3.7, 4.7 etc as I have never messed with one.

whether a rope or a neoprene, ALL of these engines (3.9, 318, 360) are a 2 pc.seal.

Dont know about 3.7, 4.7 etc as I have never messed with one.

#16

"when the mechanic had my engine out...." yikes. I am my own mechanic, nobody touches my truck but me, only exception is stuff like an alignment, something I did for years for a living but don't have access to my own unit.... and at that, I am standing "right there" telling the guy doing it exactly where I want it set.....

whether a rope or a neoprene, ALL of these engines (3.9, 318, 360) are a 2 pc.seal.

Dont know about 3.7, 4.7 etc as I have never messed with one.

whether a rope or a neoprene, ALL of these engines (3.9, 318, 360) are a 2 pc.seal.

Dont know about 3.7, 4.7 etc as I have never messed with one.

I have no way to get a motor out; there's some stuff that's far enough outside my wheel house that I'd rather pay to get it done right than do it myself.

So he doesn't get MUCH work from me; I do my own tune ups, do most work myself.

If the motor has to come out, or the transmission gets dropped, though, he gets it.

Also, if I can't figure it out.

I pay extra because he doesn't get the cheap and easy, and that's OK for me personally.

YMMV, as may the mileage of everyone else out here.

(I was going to drop the pan and try it, but when the freeze plug started leaking, I just had him do the freeze plugs, and while it was out, do the oil pump, pickup, rear seal, and a few other items. All because the motor was out already.)

RwP

#17

Hey, just wanted to let everyone know I did not drop this!!

Work has been busy. But today, is rainy, so Im going to try to get back on it. I will probably start a new post with the transmission since it is a upgrade.

But for now, ill tell you about the rear main seal.

Getting to it was a pain!! To drop the pan, I removed the motor mounts and unbolted the radiator. With my engine lift, I raised the motor as much as possible without disconnecting the accessories, etc.

Well it was not enough, so I dropped the front axle.

Got the pan off, which was rusty. I wire brushed it and sprayed with rustolum primer and black paint.

Surprised to find the seal slipped out with no resistance. After dropping the main bearing cap, I took a screwdriver and pushed on the seal. Well it slid and came out the other side about a 1/4 in. So I took a pair of needle nosed pliers and pulled it out.

I put mobil one grease on the upper half and it slid in by hand. I was surprised how easy it went in.

I used a felpro rear main seal and pan gasket.

Here are a few pictures.

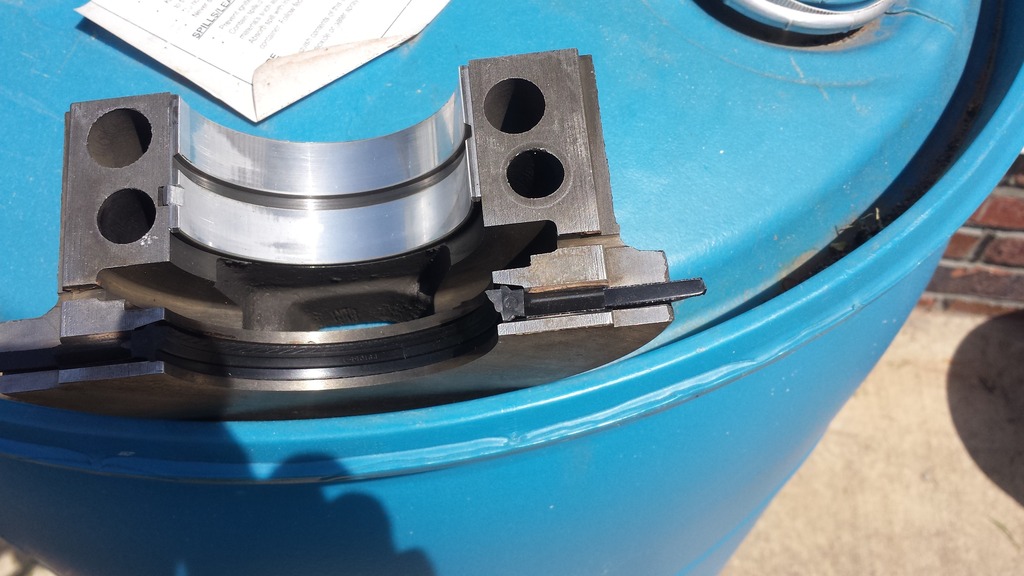

This is the old rope seal

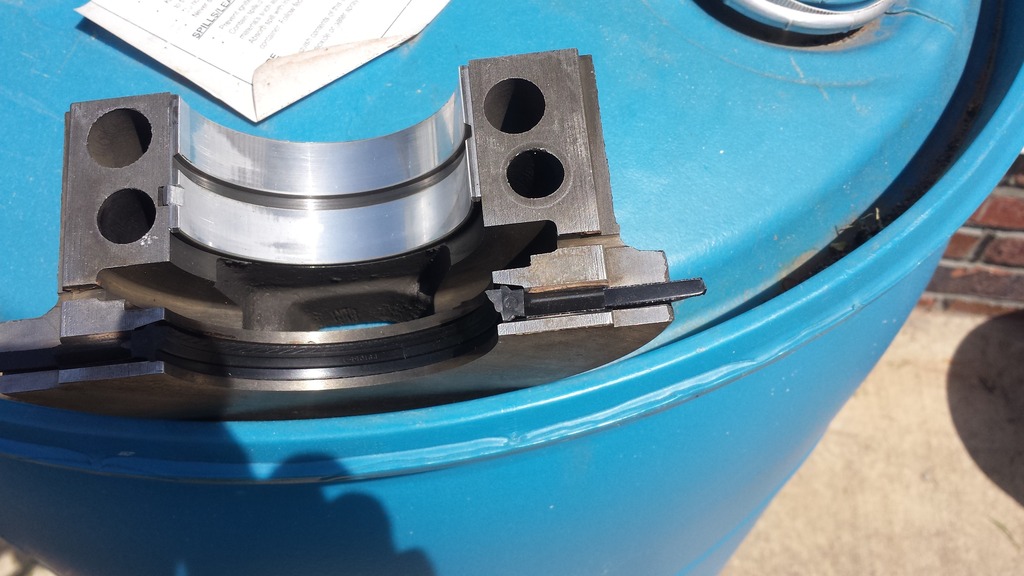

Here is the cap with the lower half installed

Here is the lower half with mobil one grease on the seal. But that is engine assy. lube on the bearing.

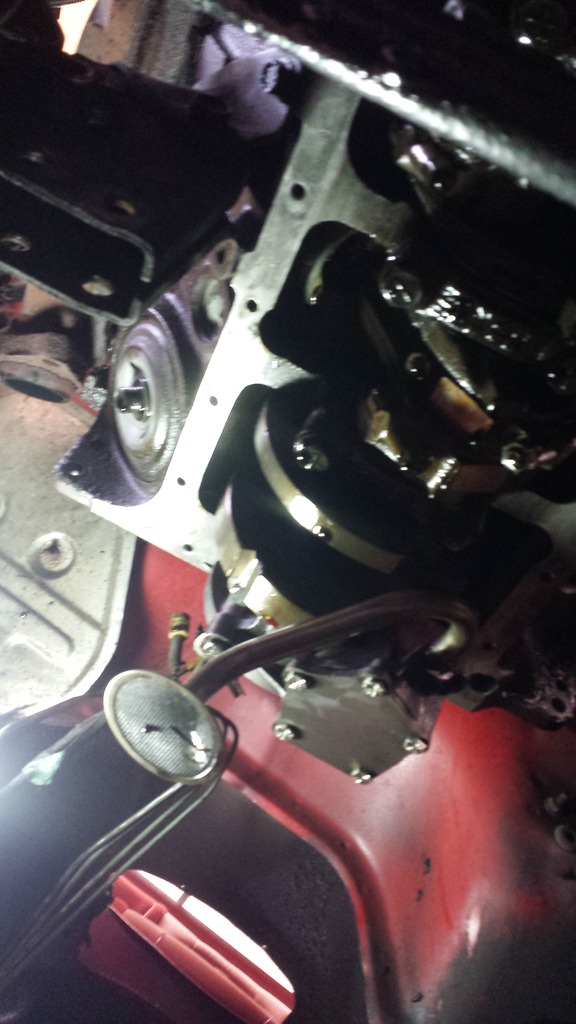

This is just a picture of the main cap and oil pump installed

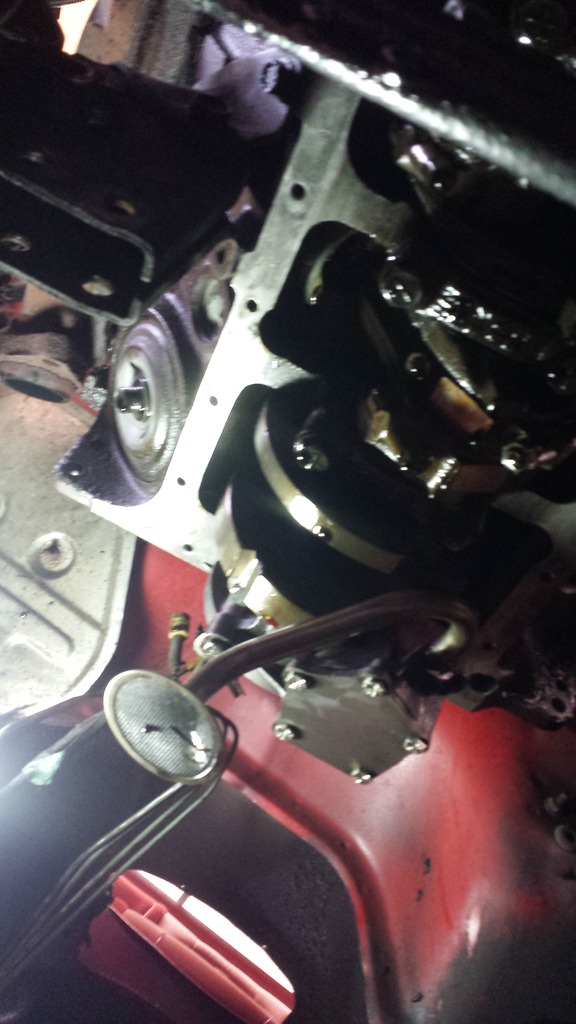

and this is just a picture of the oil pan installed

The engine is mounted back in the frame and the front axle is back in place.

So now, its on the the NV3500 NV231 upgrade!!

Work has been busy. But today, is rainy, so Im going to try to get back on it. I will probably start a new post with the transmission since it is a upgrade.

But for now, ill tell you about the rear main seal.

Getting to it was a pain!! To drop the pan, I removed the motor mounts and unbolted the radiator. With my engine lift, I raised the motor as much as possible without disconnecting the accessories, etc.

Well it was not enough, so I dropped the front axle.

Got the pan off, which was rusty. I wire brushed it and sprayed with rustolum primer and black paint.

Surprised to find the seal slipped out with no resistance. After dropping the main bearing cap, I took a screwdriver and pushed on the seal. Well it slid and came out the other side about a 1/4 in. So I took a pair of needle nosed pliers and pulled it out.

I put mobil one grease on the upper half and it slid in by hand. I was surprised how easy it went in.

I used a felpro rear main seal and pan gasket.

Here are a few pictures.

This is the old rope seal

Here is the cap with the lower half installed

Here is the lower half with mobil one grease on the seal. But that is engine assy. lube on the bearing.

This is just a picture of the main cap and oil pump installed

and this is just a picture of the oil pan installed

The engine is mounted back in the frame and the front axle is back in place.

So now, its on the the NV3500 NV231 upgrade!!

#18

After going through all that trouble getting to it, at least the seal itself was relatively easy. Nice job, I'll have to remember this - getting the oil pan off means dropping the front axle! ...And I just saw a brand new Melling oil pump for a small block Mopar, for sale on Craigslist too.

Like you, I'm finding a little (and I do mean little) time to work on a few issues. I've got the intake manifold off, and have already found 2 or 3 potential causes for the rich running and lack of power in my truck, as well as the oil leak.

Like you, I'm finding a little (and I do mean little) time to work on a few issues. I've got the intake manifold off, and have already found 2 or 3 potential causes for the rich running and lack of power in my truck, as well as the oil leak.

#19

After going through all that trouble getting to it, at least the seal itself was relatively easy. Nice job, I'll have to remember this - getting the oil pan off means dropping the front axle! ...And I just saw a brand new Melling oil pump for a small block Mopar, for sale on Craigslist too.

Like you, I'm finding a little (and I do mean little) time to work on a few issues. I've got the intake manifold off, and have already found 2 or 3 potential causes for the rich running and lack of power in my truck, as well as the oil leak.

Like you, I'm finding a little (and I do mean little) time to work on a few issues. I've got the intake manifold off, and have already found 2 or 3 potential causes for the rich running and lack of power in my truck, as well as the oil leak.

Hey Ragged, A wise man once told me he had a 5.2 flywheel that he would sell me, but if my intentions were to put a 5.9 in this truck, I should do the engine, trans, all at once. I should have listened!!

Yesterday, I did not get much done. I cleaned some parts, put 5 helicoils in the replacement transmission.

Im going to start a new thread, and try to document the conversion as much as possible.

FWIW as you have noted, the nv3500 is slightly shorter. (1/2 to 1 in?) But the np231 seems identical in size to the np207.

I think you said you used the orig. driveshaft, but have you put the front back in yet? If so did you shorten it?

Thanks

#20

I'm looking forward to your thread on the 5.9 (and trans) installation. What are you thinking in regard to the motor mounts?

Last edited by ragged89; 04-25-2017 at 12:57 PM.