Camshaft is in, 2 year ordeal over.

#1

Well,

The 2 year ordeal is over. The cam is in and running great. I'm going to write out everything I went through for future users that might want to learn from my experiences. Some of you might be able to use some of this as a reference for troubleshooting your own cam install issues. I did this under the watchful eye of several knowledgeable guys, as well as a few calls to comp cams to confirm my measuring techniques, so it should work for you should you run into any of these problems.

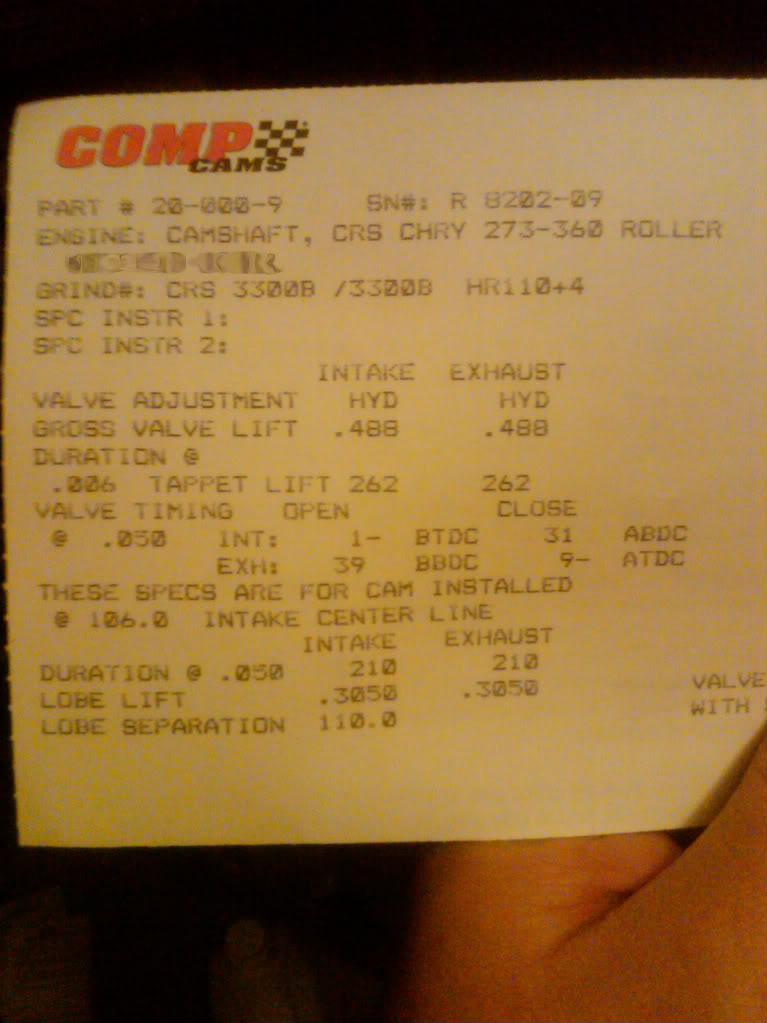

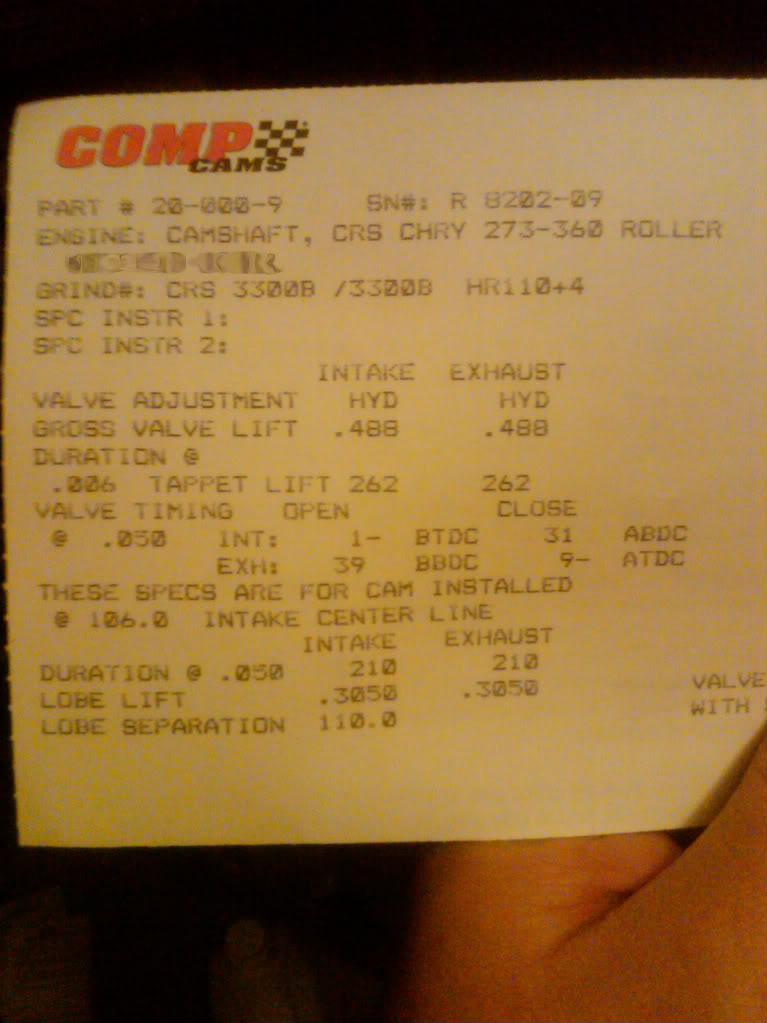

About 2 years ago I ordered a Camshaft from Marty back when KRC was open:

If you'll notice, it's very close to a KRC 210X, but with slightly less exhaust duration to keep the torque up on the 318. The lower lift you see is because it was custom ground to be used with my Harland Sharp non adjustable 1.7 ratio rocker arms. The 1.7 ratio puts the total lift at .5185". I'll explain later how I ran non adjustable rocker arms with this cam.

I had one week in the summer '09 to install it and ran into a problem:

yes, that's a camshaft bearing, and yes, it was toast:

That's me beating a camshaft bearing out and installing a new one. Not fun. Ate up most of the time I had to install the cam. The tool I used was a lisle brand camshaft bearing replacement tool. Got it at O'Reilly Autoparts for about $250.00. It "might" have gotten returned after use, as the operator didn't know what he was doing.

Tried to install the camshaft straight up and something wasn't right. Didn't have the correct tools to check it and ran out of time to install it in summer of '09 and had to table it until Winter 2010.

That winter, I had 4 days to myself to try to install the cam. I degreed it in and it everything checked out to the cam card. Then I went about checking for piston to valve clearance and ran into a problem:

http://www.youtube.com/watch?v=9rCBn7H2g_U

Oops. The old cam must go back in. ****

Did a lot of research on the cam. Seems as though the 2.02" intake valve with a flat topped 318 piston didn't jive with the cam. I thought about retarding the cam to get the adequate clearance, but was assured that retarding it would ruin the aspects of the cam. I even bought a Mopar R/T+10 cam that is still sitting in the garage as a possible replacement. When I posted up about the R/T+10 cam, I was convinced by a few guys over at Bionic who had followed my saga that I ought to try to get that cam that Marty spec'd out to run, as it should really open up the combo of mods I already had.

I started researching how and if there was a way to make that cam fit, and with the help of a few guys over at bionic, I found David Linderholm at www.lindytools.com. He made me this:

That is a piston notching tool. It cuts reliefs into pistons, using the cylinder head and valve guide as a reference for each valve. You just put it into the head in place of the valve that needed more clearance (intake in my case), use some feeler gauges to set the depth of the cut at the top of the valve guide, tighten down the collar, and turn the cutter with a drill. It ends up looking like this:

Pretty snazzy, huh? I ended up taking .042" off the top of each piston on the intake side. That gave me an easy .080 clearance for the valves that were in question in the video. David's tool was designed to make a nice beveled cut to avoid leaving any sharp edges in the piston (reduces hot spots that cause detonation), and he made it in a 2.090" size to give me adequate side pocket clearance as well. I'm running 2.02" inch valves so that gave me .035' radial pocket clearance on each side of the valve. Though my valves never touched the pistons, the radial pocket clearance wasn't absolutely necessary, but it's extra insurance nonetheless. There's no telling exactly how much that valve moves around in there, so no point in taking chances. If you ever need one of these things, I can't recommend David enough. Awesome guy to talk to. BTW, the stock valve stem is 8mm, he'll need to know the valve stem thickness to make the til for you, so if you run aftermarket heads with different valve stem thickness, you'll need to know the correct sized stem to get. He can also make them with carbide cutters if you have hypereutectic or forged pistons. Isky makes a similar tool, but they are more expensive than David's, don't have exact stem or cutting surface sizes, and are not suited to use on harder pistons.

I ended up taking .042" off the top of each piston on the intake side. That gave me an easy .080 clearance for the valves that were in question in the video. David's tool was designed to make a nice beveled cut to avoid leaving any sharp edges in the piston (reduces hot spots that cause detonation), and he made it in a 2.090" size to give me adequate side pocket clearance as well. I'm running 2.02" inch valves so that gave me .035' radial pocket clearance on each side of the valve. Though my valves never touched the pistons, the radial pocket clearance wasn't absolutely necessary, but it's extra insurance nonetheless. There's no telling exactly how much that valve moves around in there, so no point in taking chances. If you ever need one of these things, I can't recommend David enough. Awesome guy to talk to. BTW, the stock valve stem is 8mm, he'll need to know the valve stem thickness to make the til for you, so if you run aftermarket heads with different valve stem thickness, you'll need to know the correct sized stem to get. He can also make them with carbide cutters if you have hypereutectic or forged pistons. Isky makes a similar tool, but they are more expensive than David's, don't have exact stem or cutting surface sizes, and are not suited to use on harder pistons.

Anyway, after all that mess was cut and cleaned, I still had to figure out the pushrod length. I was using the Harland Sharp non-adjustable pedestal mount rocker arms. There is no way to adjust the rocker arm to set preload, it essentially built into the rocker arm when you tighten it down to spec. As most of you guys that swap cams know, there is no guarantee that an aftermarket cam has the same base circle as the stock cam, and so just slapping the stock pushrods in the engine without a way to adjust the lash to set proper preload on the lifter is not wise. Here's an article on why lifter preload is important:

http://www.small-block-chevy.com/cb_6.htm

Yeah it's Chevy, but it still applies to our engines as well.

Since I was intent on not wasting a perfectly good set of roller rockers, or shelling out another $500 dollars on adjustable 1.7 rocker arms, I used this:

http://www.summitracing.com/parts/CCA-7702-1/

That is an adjustable pushrod checking tool from comp cams, and part number 7702 is the correct one for our engine. You can screw it in and out and it will change the length of the pushrod to very easy to measure amounts so you can check the valve train geometry on the valve as the rocker arm crosses it. Here's an article from comp cams that describes what you should be looking for:

http://www.compcams.com/Pages/417/va...-geometry.aspx

There is one caveat: our engines use hydraulic roller lifters. These lifters will compress under load and the plunger will sink into the lifter. You CANNOT use a hydraulic lifter to check your valve train geometry, it will collapse under the weight of the valve spring and you won't get an accurate reading. I have been told that a checking spring will not collapse a lifter, but reading a pattern on the valve stem is harder as there is not much pressure, and I was not taking any chances this time.

In order to combat lifter deflation, you have to build a solid "hydraulic" lifter. Here's how:

Pull the guts out of an old hydraulic lifter that you know is the correct part for the engine. Once you get to the spring in the bottom of the lifter, pull it out and set it aside. You won't be using it. Got to the local hardware store and buy a package of #6 flat washers. Stack the flat washers into the bottom of the lifter (mine took 5 washers, I think) and replace all the components of the lifter, EXCEPT THE SPRING and check the TOP of the lifter cup. The top of the cup should just come up even with the groove for the snap ring. Once you have the correct height, put the snap ring in. Mark this lifter with some bright paint, you DO NOT ever want to mistakenly run this lifter in your engine. You now have a lifter that is the correct height for your engine, and will not deflate, or preload.

Anyway, I placed the new solid "hydraulic" lifter in the lifter bore of the #1 intake cylinder, and with the adjustable pushrod, I set varying lengths of 6.850-6.950 with the adjustable pushrod to check the valve train geometry, by torquing down an old head gasket to 80 ft/lbs, and the rocker arm to the 21ft/lbs, then spinning the engine over by hand about 4-6 times.

Now mind you, the solid lifter will not allow any lifter preload, it simply won't compress. You must find the length that creates a pattern over the center of the valve when you crank the engine over by hand, then add .030 to that length when you order pushrods to get the proper lifter preload.

How do you check the pattern? Machinist's dye on the top of the valve:

After you crank the engine around a few times, remove the rocker arm and look at the pattern that had rubbed off. If it's centered, you got it. Be careful about going too long on the adjustable pushrod with a solid lifter; it will transfer all the excess lift to the valve and push it open into the cylinder. If your piston to valve clearance is tight, you could run the risk of pushing the valve into the piston turning the engine over.

My best pattern was with the adjustable pushrod at a length of 6.900". Adding .030" to that length gave me a length of 6.930" for the correct length pushrod. Now, I felt like that pattern was just a hair too far toward the exhaust headers, signifying that the pushrod was just a bit too long (too short a pushrod will skew toward the intake manifold). The stock pushrod length was 6.925", so in my case, I got to reuse the stock pushrods.

That was a "my case only" statement. You CANNOT assume that the stock length pushrods will work with an aftermarket cam on the non adjustable Harland Sharp, or even the stock rocker arms; you MUST measure!

EDIT: 8-6-11 Valve train was still a bit noisy after 2 weeks. Went with a longer pushrod 6.936". Those are Ford standard length for an 80's 5.0L. Edelbrock makes a hardened set I got at summit racing for $60. P/N 6938 I believe. It's the pushrod they recommend with the eddy heads they sell for our engines.

I know that many Hughes cams are reground stock cam cores. They get the extra lift by cutting the base circle of the cam down, which requires a longer pushrod to compensate for the smaller base circle. They should know the correct length, and you should ask about it, if you order a reground cam from them.

After I buttoned up the engine and ran it, the thing ticked like crazy! I thought for sure I had messed up the pushrod measurement and was looking at a demolished valve train. Marty was monitoring my progress over at Bionic and told me that since I reused my lifters, they would tick for a few days until they got used to the new length they were being asked to travel by the increased camshaft lift.

The paranoid person that I was, before I reassembled the entire engine, I painted all the valve tips with machinist's dye. After I heard the ticking and read Marty's post, I pulled the valve cover off and rocker arms, and sure enough, the pattern was still good. Marty was right about the lifter ticking until it "grooved" into the new lift.

Anyway, the cam's in and running great! I learned way more than I maybe wanted to doing this, so I figured I would share with you all so some of you can learn from the problems I encountered and troubleshoot some possible solutions.

Cheers all!

The 2 year ordeal is over. The cam is in and running great. I'm going to write out everything I went through for future users that might want to learn from my experiences. Some of you might be able to use some of this as a reference for troubleshooting your own cam install issues. I did this under the watchful eye of several knowledgeable guys, as well as a few calls to comp cams to confirm my measuring techniques, so it should work for you should you run into any of these problems.

About 2 years ago I ordered a Camshaft from Marty back when KRC was open:

If you'll notice, it's very close to a KRC 210X, but with slightly less exhaust duration to keep the torque up on the 318. The lower lift you see is because it was custom ground to be used with my Harland Sharp non adjustable 1.7 ratio rocker arms. The 1.7 ratio puts the total lift at .5185". I'll explain later how I ran non adjustable rocker arms with this cam.

I had one week in the summer '09 to install it and ran into a problem:

yes, that's a camshaft bearing, and yes, it was toast:

That's me beating a camshaft bearing out and installing a new one. Not fun. Ate up most of the time I had to install the cam. The tool I used was a lisle brand camshaft bearing replacement tool. Got it at O'Reilly Autoparts for about $250.00. It "might" have gotten returned after use, as the operator didn't know what he was doing.

Tried to install the camshaft straight up and something wasn't right. Didn't have the correct tools to check it and ran out of time to install it in summer of '09 and had to table it until Winter 2010.

That winter, I had 4 days to myself to try to install the cam. I degreed it in and it everything checked out to the cam card. Then I went about checking for piston to valve clearance and ran into a problem:

http://www.youtube.com/watch?v=9rCBn7H2g_U

Oops. The old cam must go back in. ****

Did a lot of research on the cam. Seems as though the 2.02" intake valve with a flat topped 318 piston didn't jive with the cam. I thought about retarding the cam to get the adequate clearance, but was assured that retarding it would ruin the aspects of the cam. I even bought a Mopar R/T+10 cam that is still sitting in the garage as a possible replacement. When I posted up about the R/T+10 cam, I was convinced by a few guys over at Bionic who had followed my saga that I ought to try to get that cam that Marty spec'd out to run, as it should really open up the combo of mods I already had.

I started researching how and if there was a way to make that cam fit, and with the help of a few guys over at bionic, I found David Linderholm at www.lindytools.com. He made me this:

That is a piston notching tool. It cuts reliefs into pistons, using the cylinder head and valve guide as a reference for each valve. You just put it into the head in place of the valve that needed more clearance (intake in my case), use some feeler gauges to set the depth of the cut at the top of the valve guide, tighten down the collar, and turn the cutter with a drill. It ends up looking like this:

Pretty snazzy, huh?

Anyway, after all that mess was cut and cleaned, I still had to figure out the pushrod length. I was using the Harland Sharp non-adjustable pedestal mount rocker arms. There is no way to adjust the rocker arm to set preload, it essentially built into the rocker arm when you tighten it down to spec. As most of you guys that swap cams know, there is no guarantee that an aftermarket cam has the same base circle as the stock cam, and so just slapping the stock pushrods in the engine without a way to adjust the lash to set proper preload on the lifter is not wise. Here's an article on why lifter preload is important:

http://www.small-block-chevy.com/cb_6.htm

Yeah it's Chevy, but it still applies to our engines as well.

Since I was intent on not wasting a perfectly good set of roller rockers, or shelling out another $500 dollars on adjustable 1.7 rocker arms, I used this:

http://www.summitracing.com/parts/CCA-7702-1/

That is an adjustable pushrod checking tool from comp cams, and part number 7702 is the correct one for our engine. You can screw it in and out and it will change the length of the pushrod to very easy to measure amounts so you can check the valve train geometry on the valve as the rocker arm crosses it. Here's an article from comp cams that describes what you should be looking for:

http://www.compcams.com/Pages/417/va...-geometry.aspx

There is one caveat: our engines use hydraulic roller lifters. These lifters will compress under load and the plunger will sink into the lifter. You CANNOT use a hydraulic lifter to check your valve train geometry, it will collapse under the weight of the valve spring and you won't get an accurate reading. I have been told that a checking spring will not collapse a lifter, but reading a pattern on the valve stem is harder as there is not much pressure, and I was not taking any chances this time.

In order to combat lifter deflation, you have to build a solid "hydraulic" lifter. Here's how:

Pull the guts out of an old hydraulic lifter that you know is the correct part for the engine. Once you get to the spring in the bottom of the lifter, pull it out and set it aside. You won't be using it. Got to the local hardware store and buy a package of #6 flat washers. Stack the flat washers into the bottom of the lifter (mine took 5 washers, I think) and replace all the components of the lifter, EXCEPT THE SPRING and check the TOP of the lifter cup. The top of the cup should just come up even with the groove for the snap ring. Once you have the correct height, put the snap ring in. Mark this lifter with some bright paint, you DO NOT ever want to mistakenly run this lifter in your engine. You now have a lifter that is the correct height for your engine, and will not deflate, or preload.

Anyway, I placed the new solid "hydraulic" lifter in the lifter bore of the #1 intake cylinder, and with the adjustable pushrod, I set varying lengths of 6.850-6.950 with the adjustable pushrod to check the valve train geometry, by torquing down an old head gasket to 80 ft/lbs, and the rocker arm to the 21ft/lbs, then spinning the engine over by hand about 4-6 times.

Now mind you, the solid lifter will not allow any lifter preload, it simply won't compress. You must find the length that creates a pattern over the center of the valve when you crank the engine over by hand, then add .030 to that length when you order pushrods to get the proper lifter preload.

How do you check the pattern? Machinist's dye on the top of the valve:

After you crank the engine around a few times, remove the rocker arm and look at the pattern that had rubbed off. If it's centered, you got it. Be careful about going too long on the adjustable pushrod with a solid lifter; it will transfer all the excess lift to the valve and push it open into the cylinder. If your piston to valve clearance is tight, you could run the risk of pushing the valve into the piston turning the engine over.

My best pattern was with the adjustable pushrod at a length of 6.900". Adding .030" to that length gave me a length of 6.930" for the correct length pushrod. Now, I felt like that pattern was just a hair too far toward the exhaust headers, signifying that the pushrod was just a bit too long (too short a pushrod will skew toward the intake manifold). The stock pushrod length was 6.925", so in my case, I got to reuse the stock pushrods.

That was a "my case only" statement. You CANNOT assume that the stock length pushrods will work with an aftermarket cam on the non adjustable Harland Sharp, or even the stock rocker arms; you MUST measure!

EDIT: 8-6-11 Valve train was still a bit noisy after 2 weeks. Went with a longer pushrod 6.936". Those are Ford standard length for an 80's 5.0L. Edelbrock makes a hardened set I got at summit racing for $60. P/N 6938 I believe. It's the pushrod they recommend with the eddy heads they sell for our engines.

I know that many Hughes cams are reground stock cam cores. They get the extra lift by cutting the base circle of the cam down, which requires a longer pushrod to compensate for the smaller base circle. They should know the correct length, and you should ask about it, if you order a reground cam from them.

After I buttoned up the engine and ran it, the thing ticked like crazy! I thought for sure I had messed up the pushrod measurement and was looking at a demolished valve train. Marty was monitoring my progress over at Bionic and told me that since I reused my lifters, they would tick for a few days until they got used to the new length they were being asked to travel by the increased camshaft lift.

The paranoid person that I was, before I reassembled the entire engine, I painted all the valve tips with machinist's dye. After I heard the ticking and read Marty's post, I pulled the valve cover off and rocker arms, and sure enough, the pattern was still good. Marty was right about the lifter ticking until it "grooved" into the new lift.

Anyway, the cam's in and running great! I learned way more than I maybe wanted to doing this, so I figured I would share with you all so some of you can learn from the problems I encountered and troubleshoot some possible solutions.

Cheers all!

Last edited by aim4squirrels; 08-06-2011 at 11:57 AM.

#4

Not necessarily, mine was a very unique case of problems. If you don't go off the beaten path with your cam choice, it can be as simple as installing it straight up and driving on.

The 5.9 liter engine has lots more piston to valve clearance, as the pistons are dished. And if you aren't running 2.02 valves, you'd have even more. I see you have a 5.2, so I'd try to get ahold of Marty over at bionic dodge, or call hughes engines when selecting your cam.

Or you could order up my cam off that cam card from comp cams if you don't mind fly cutting the pistons. be sure to ask about tuning with the 95 though, you don't have as many options to wander too far off.

be sure to ask about tuning with the 95 though, you don't have as many options to wander too far off.

Assuming they cut it exactly the same, the stock valve train components will work. I'd advise checking it anyway.

I have a mopar RT +10 cam that is supposed to be computer friendly. I didn't install or degree it, so I know nothing about how it will act in your engine. It's been used about 5000 miles on it, and I haven't even looked at it yet, but let me know if you are interested.

Nobody tends to build up a 5.2, at least not as much as the 5.9, and 2.02 valves are generally considered too big for the run of the mill, daily driven 5.2. If I had it to do over, I'd probably have stayed at 1.92 or 1.97 valves.

The 5.9 liter engine has lots more piston to valve clearance, as the pistons are dished. And if you aren't running 2.02 valves, you'd have even more. I see you have a 5.2, so I'd try to get ahold of Marty over at bionic dodge, or call hughes engines when selecting your cam.

Or you could order up my cam off that cam card from comp cams if you don't mind fly cutting the pistons.

be sure to ask about tuning with the 95 though, you don't have as many options to wander too far off.

be sure to ask about tuning with the 95 though, you don't have as many options to wander too far off.Assuming they cut it exactly the same, the stock valve train components will work. I'd advise checking it anyway.

I have a mopar RT +10 cam that is supposed to be computer friendly. I didn't install or degree it, so I know nothing about how it will act in your engine. It's been used about 5000 miles on it, and I haven't even looked at it yet, but let me know if you are interested.

Nobody tends to build up a 5.2, at least not as much as the 5.9, and 2.02 valves are generally considered too big for the run of the mill, daily driven 5.2. If I had it to do over, I'd probably have stayed at 1.92 or 1.97 valves.

Last edited by aim4squirrels; 07-25-2011 at 05:49 PM.

#7

Trending Topics

#8

#9

Not necessarily, mine was a very unique case of problems. If you don't go off the beaten path with your cam choice, it can be as simple as installing it straight up and driving on.

The 5.9 liter engine has lots more piston to valve clearance, as the pistons are dished. And if you aren't running 2.02 valves, you'd have even more. I see you have a 5.2, so I'd try to get ahold of Marty over at bionic dodge, or call hughes engines.

Or you could order up my cam off that cam card from comp cams if you don't mind fly cutting the pistons. be sure to ask about tuning with the 95 though, you don't have as many options to wander too far off.

be sure to ask about tuning with the 95 though, you don't have as many options to wander too far off.

Assuming they cut it exactly the same, the stock valve train components will work. I'd advise checking it anyway.

I have a mopar RT +10 cam that is supposed to be computer friendly. I didn't install or degree it, so I know nothing about how it will act in your engine. It's been used about 5000 miles on it, and I haven't even looked at it yet, but let me know if you are interested.

Nobody tends to build up a 5.2, at least not as much as the 5.9, and 2.02 valves are generally considered too big for the run of the mill, daily driven 5.2. If I had it to do over, I'd probably have stayed at 1.92 or 1.97 valves.

The 5.9 liter engine has lots more piston to valve clearance, as the pistons are dished. And if you aren't running 2.02 valves, you'd have even more. I see you have a 5.2, so I'd try to get ahold of Marty over at bionic dodge, or call hughes engines.

Or you could order up my cam off that cam card from comp cams if you don't mind fly cutting the pistons.

be sure to ask about tuning with the 95 though, you don't have as many options to wander too far off.

be sure to ask about tuning with the 95 though, you don't have as many options to wander too far off.Assuming they cut it exactly the same, the stock valve train components will work. I'd advise checking it anyway.

I have a mopar RT +10 cam that is supposed to be computer friendly. I didn't install or degree it, so I know nothing about how it will act in your engine. It's been used about 5000 miles on it, and I haven't even looked at it yet, but let me know if you are interested.

Nobody tends to build up a 5.2, at least not as much as the 5.9, and 2.02 valves are generally considered too big for the run of the mill, daily driven 5.2. If I had it to do over, I'd probably have stayed at 1.92 or 1.97 valves.

I have a set of R/t 1.92s to go on the truck and will be running HS 1.6 nonadj rockers.

I was leaning toward this cam what do you think

http://www.compcams.com/Company/CC/c...?csid=659&sb=2

#10