Dodge Ram: Why Don't My Reverse Lights Work?

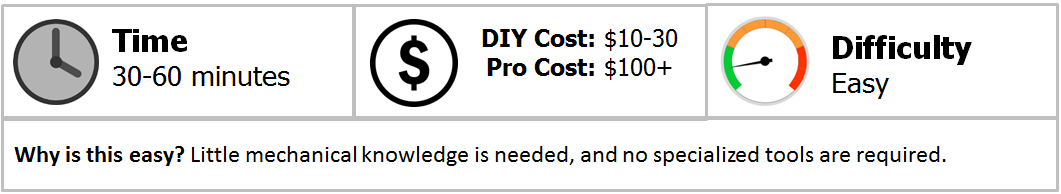

If the reverse lights on your Dodge Ram are not working, this problem can be easily remedied in your own garage.

This article applies to the Dodge Ram (1994-present).

Electrical problems with your Dodge truck are some of the most annoying and frustrating issues to solve. When your reverse lights aren't working properly or won't come on at all, there are a bunch of areas that could be the source of the problem. A professional diagnosis won't come cheap even if the repair is easy. Searching for the culprit is the most difficult aspect of this job. You can save yourself a good deal of money by seeking out the problem yourself in your own garage. Start with the easiest and most common possibilities before venturing into the more labor intensive repairs. Finding and ultimately fixing the problem shouldn't take very long and the costs are really low if you do this yourself.

Materials Needed

- Replacement bulbs

- Sandpaper

- Transmission fluid

- Voltmeter/OHm meter

- Wire snips

- Shrink wrap for wiring

- Replacement fuses

Step 1 – Check the reverse light bulbs

They might be burnt out.

It may be quite obvious, but pull the reverse light bulbs and make sure that they are still good. If not, simply replace them.

If the bulbs are brand new or otherwise in good working order, move on to Step 2.

Step 2 – Check the bulb socket for corrosion, dirt or broken wires

There could be a disconnect between the bulb and the socket.

Since you already have the bulbs pulled, now is a good time to take a look at the socket. If there is corrosion on the contacts, try using some sandpaper to scrape the corrosion off. This should make the connections with the bulb good and is an inexpensive fix. If there is no noticeable corrosion, check the wires behind the socket to make sure there are no cuts or breaks. Wiggle the wires back and forth to expand any possible cracks. If they are bad, snip, splice and apply shrink wrap to restore the connection.

If the socket and wires are good, move on to Step 3.

Step 3 – Open the fuse box and look for the reverse fuse

The fuse may be blown.

Checking for a blown fuse seems quite obvious as well, but if this is the culprit, it's another inexpensive fix that anyone can do. Wouldn't it be really annoying to pay a professional for parts and labor to replace a blown fuse? If the fuse is blown, replace it; check the reverse lights and if it blows again, you'll need to start tracing the wires because there's a short somewhere down the line.

If the fuse is good, it's time to get your hands dirty.

Step 4 – Test and replace the neutral safety switch

The neutral safety switch may not be closing the circuit properly when the reverse gear is engaged.

The neutral safety switch has a couple of different functions. It should not allow the truck to start out of either neutral or park. A simple test is to put it in drive or reverse and try to start the vehicle. Please use common sense and make sure there is no danger to life or property when you do this. This will obviously indicate the problem right away, but another function of the switch is to close the circuit when reverse is set which will turn on the lights. There is a little plunger-type pin in this switch that should extend to close this circuit. It could be bent, corroded or completely shot. Replacing this switch is simple and should cost less than $30.

- The switch is located on the driver's side of the transmission up near the front linkage.

- It is screwed into the tranny, so when removed, you will have some fluid loss.

- Before you remove it, get the replacement ready with some Teflon tape wrapped around the threads.

- As fast as safely possible, remove the old switch and insert the new.

- You will need a deep-well socket for this and there is no real easy way to access either from above or below. It's a tight squeeze.

- Remember to top off your tranny fluid at the reservoir to be safe.

Pro Tip

Transmission fluid is some nasty stuff. Make sure you have a shop rag handy to wipe up any spills.

Related Discussions

- Reverse Lights Don't Work, Need Help - Dodgeforum.com

- No Reverse Lights - Dodgeforum.com

- My Reverse Lights Won't Come On - Dodgeforum.com