DIY - Deleting the Transmission Check Valve (46RH/46RE)

#1

Deleting the Transmission Check Valve

Well, here's a little write up to remove the tranny check valve in the return line to increase flow to the trans and hopefully remove a common failure point in the Dodge 46re transmission. The replacement is a return line with no check valve that replaces the current line without hacking up any of the truck's trans lines or fittings.

Sorry for the few out of focus pictures, my camera doesn't like to focus without a flash which was necessary for some pics.

Tools needed:

7/8" open end wrench

3/4" open end wrench

a flat head screwdriver

crescent wrench for various metric fittings somewhere between 17mm and 21mm

wire cutters

3/8" quick disconnect tool

trans oil catch pan

Parts needed:

2 - 3/8" nozzle to pipe fitting (yes you need 2 of these!) (NAPA part #05706B106)

1 - 3/8" to 3/8" male-to-male coupler (will research P/N)

1 - 3/8" pipe thread to flare thread converter (will research P/N)

1 - quick disconnect fitting (NAPA part #730-5027)

1 - 3/8" to 1/4" reducer coupling (NAPA part #3300X6X4)

2 - hose clamps (NAPA part #5051212)

1 ft of 3/8" ID trans cooler line (NAPA part #H1937)

1 or 2 quarts ATF +4 trans fluid

Total price: ~$35 for parts

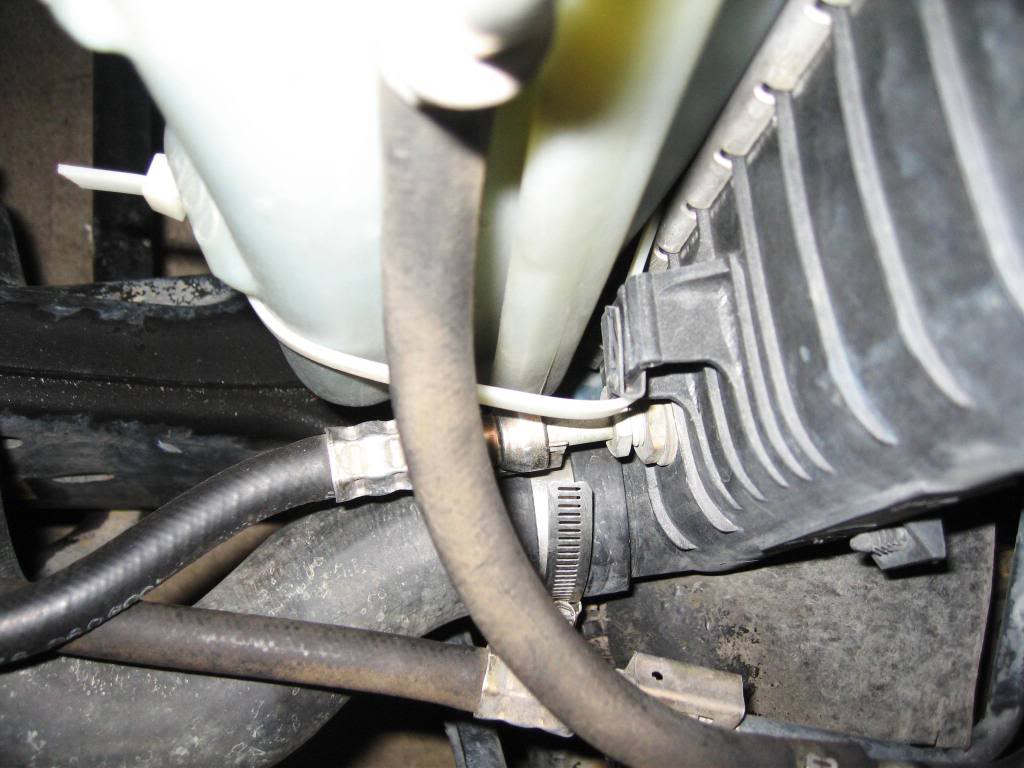

Okay, here we go. The first pic is of the check valve as it sits in the stock truck in the transmission return line from the radiator. The large brass fitting contains the the check valve in question. The purpose of this check valve is to keep the Torque Converter filled with transmission fluid when the truck is off so the next time you start it, you can take off without waiting for the pump to fill the converter back up.

So why on earth would you want to remove this? Well, if you have debris in your trans fluid from normal wear and tear, a common place for it to collect is in the check valve. When this happens, the fluid flow can eventually stop and with no way to cool the internals of the transmission, it will overheat and die. A failure of this type usually results in a rebuild to the tune of at least $1200 or more.

The next pic is the connection on the radiator side:

It is typically held on with a quick connect fitting and you will need to first pop off the safety connection with a flat head screw driver. A quick disconnect tool can be used to remove the connection to the radiator, pictured here (the tool is in the middle of the pic):

I prefer the metal disconnect tools to the plastic ones as the short plastic circular tools don't really get far enough into the quick connect fitting to release the spring loaded latches. The metal ones are so much faster than wrestling with a cheapo plastic circle that gets chewed up and thrown out. Harbor Freight has them here.

Make sure you place a catch pan under the fitting before you disconnect it as trans fluid will start to drip from the radiator. You simply slide the disconnect tool over the trans cooler line on the radiator side with the flanges pointing toward the check valve and press the tool into the fitting and then pull the fitting and hose away from the radiator. Then remove the tool. The black band around the tool is actually a rubber band and assists you in closing and holding the tool around the pipe you are using it on. I suggest you leave it on the tool and just shove the disconnect tool straight down onto the radiator pipe.

Now you can remove the check valve side of the hose. The 7/8" wrench should fit on the check valve and the 3/4" should go on the silver connector on the the trans return line. The brass fitting might have corroded a bit so a shot of penetrating oil will help break it loose. When you remove the check valve tube trans fluid will drip from the trans line, so position your drip pan under there as well. I find the large 15 quart Blitz pans can cover both drips in one pan and work well.

After you remove the check valve line, turn it quick connect side down and let the trans fluid drip out. You can then take a peek in the check valve side to see the check valve inside the fitting. It's tiny and once you see it, you'll understand why it's a restriction to the system and how debris can accumulate there, especially is the tranny doesn't see a regular servicing.

Next we need to construct a new replacement hose with fittings.

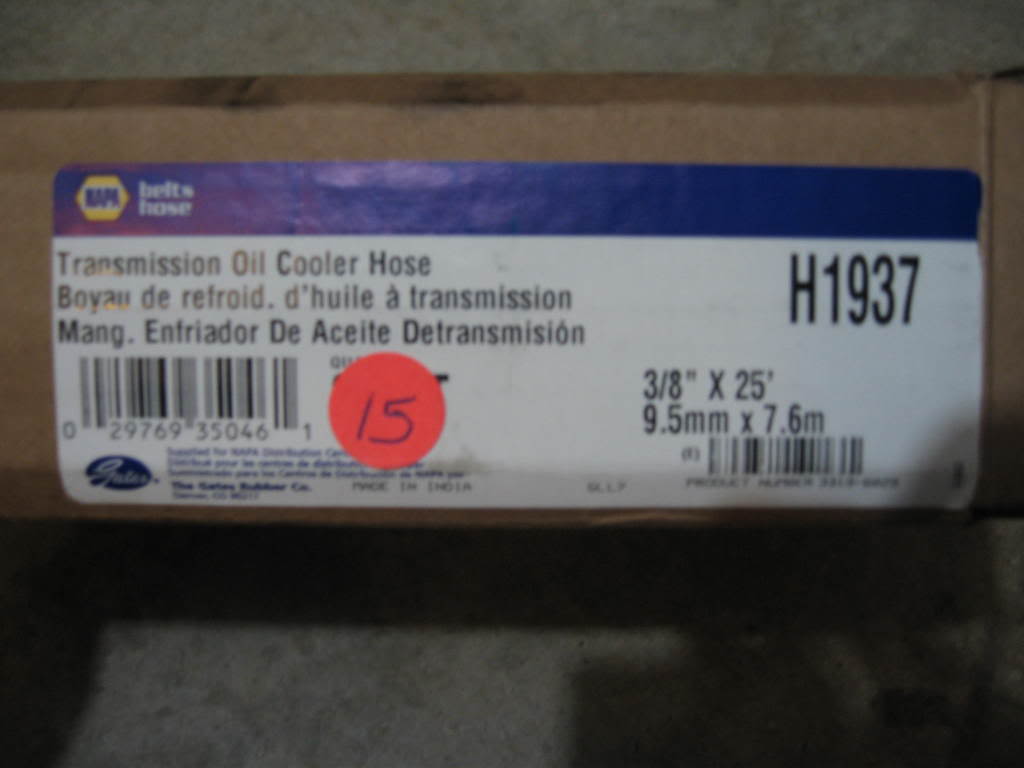

First we need 1 ft of hose. Make sure it is 3/8" ID trans cooler line hose and nothing else! Trans line hose is reinforced and rated for +150PSI, any less and the hose will eventually swell and split, (probably while you're driving) and then you'll lose fluid and overheat. Here's a pic of the NAPA trans line (I bought their last 3 feet, so they gave me the box):

That hose was rated for 400PSI!

Here's a pic of the check valve side brass fittings (you can see these assembled in the quick disconnect tool pic posted earlier. It's the piece just above the tool.)

The nozzle end will go into the hose and then you'll use the band clamps to secure it. The nozzle will slide right into the hose and the band clamp will fit perfectly over the flat portion of the nozzle. The tip on the nozzle serves as a catch so that the band clamp (when tightened down) can't slide backward. The reason that you can't use just the nozzle piece is because the coupler in the truck on the check valve side is a flare thread which is different from pipe thread. The coupler in the pic is just a simple 3/8" male-to-male coupler. The large coupler was 7/8" on the outside, but the nozzle and flare pieces were 17mm (IIRC), so I just used a crescent wrench as I didn't have a larger metric wrench. RTV should not be needed if you get the fittings tight, but won't hurt if you want to use it, just use sparingly on the threads and make sure it is highly oil resistant and can take at least 250 degress.

Here's a pic of the 3 pieces that go onto the radiator side of the hose (I believe that coupler was 21mm on the outside):

And here's a close up pic of the NAPA replacement Quick Connect fitting. Notice it says DODGE/JEEP at the top:

The parts guy said he could order a quick connect with a female end that might attached directly to the 3/8" nozzle without the reducer, but I wasn't going to wait a day for a "maybe fits" part. I just bought this one and used a reducer they had in stock.

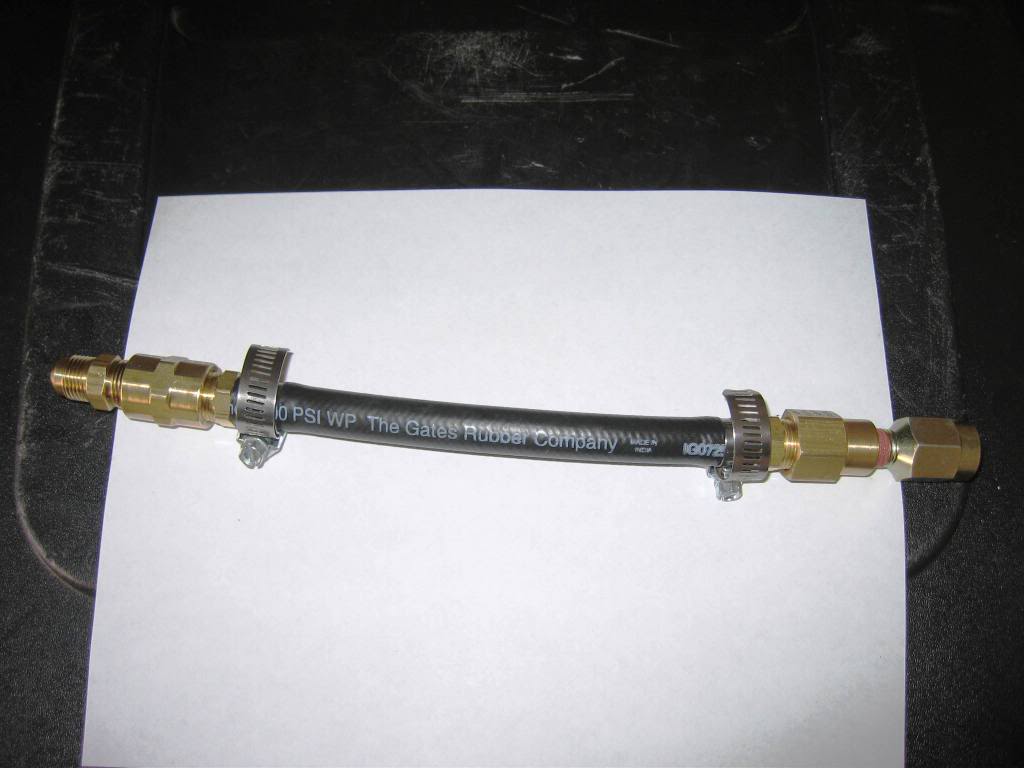

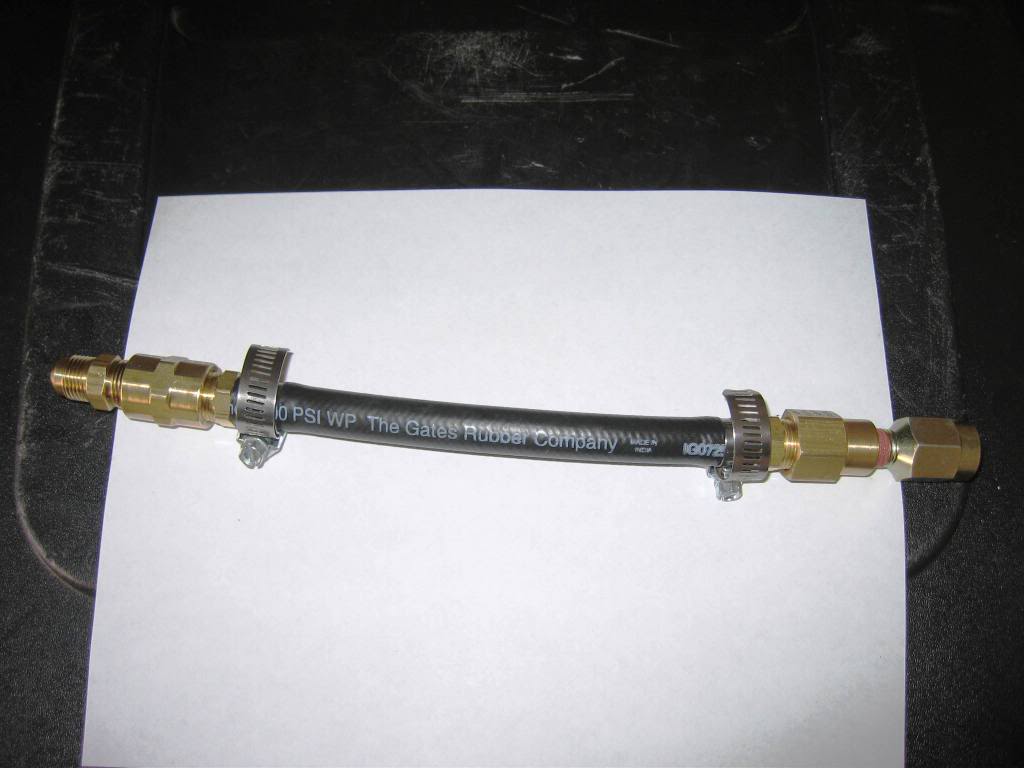

Here's the replacement hose completely assembled:

1 ft of trans tubing will probably be a little too long for the setup so you can use wire cutters to cut the trans tubing to size. Just use the old check valve unit to judge length before you cut. A razor blade won't work because the trans line is reinforced with steel mesh to keep it from expanding. Just stuff the replacement check valve fitting unit in one end of the hose, clamp it down with a hose clamp and hold it up to the old check valve line before you cut. Remember to measure twice and cut once! The new fittings will make the whole unit a little longer than the old one, so don't judge rubber tubing to rubber tubing when you cut. Throw another hose clamp on the hose before inserting the radiator side coupling. Insert radiator side coupling and tighten down the hose clamp over the fitting's nozzle end.

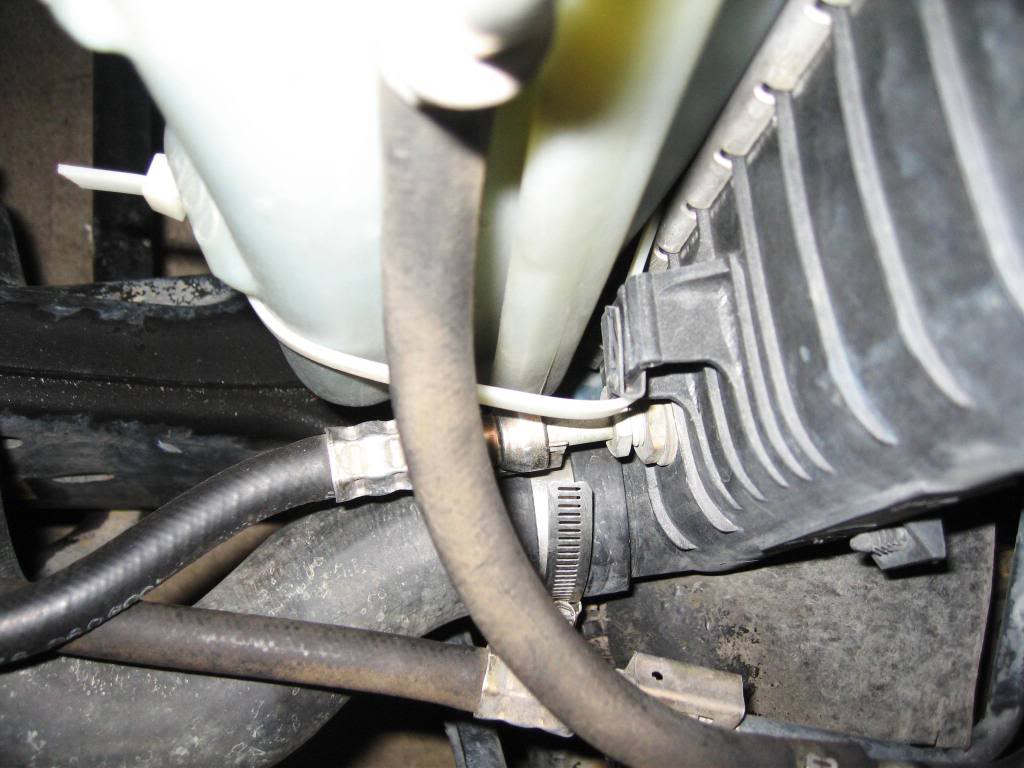

Tighten up the flare end onto the coupler in the truck and push the quick connect side onto the radiator. You can now remove the drip pan. Recheck all of the connections. Here's a pic of it installed:

Engage the emergency brake and start up the truck and put it in Neutral. Let the truck heat up to operating temp and check the trans fluid level on a level road or parking lot. Add more ATF +4 as needed.

It's a good idea to let the truck idle in neutral for about 10 seconds before taking off after the truck has sit for an extended length of time. This will allow the trans fluid pump to refill the Torque Converter so you don't bog and stall as you try to take off.

Enjoy your new found peace of mind.

This setup is also nice if you ever want to add an external cooler or filter to the trans return line. Just remove the hose from the fittings via the hose clamps and place the cooler or filter unit in between the two couplings and pipe the hoses into your current couplings. Just check to make sure that if there is a recommended direction of flow, you pipe it in correctly. The flow for the check valve portion we've removed is from radiator to transmission (the return line). You'll notice the flow direction is marked on the old check valve itself.

Well, here's a little write up to remove the tranny check valve in the return line to increase flow to the trans and hopefully remove a common failure point in the Dodge 46re transmission. The replacement is a return line with no check valve that replaces the current line without hacking up any of the truck's trans lines or fittings.

Sorry for the few out of focus pictures, my camera doesn't like to focus without a flash which was necessary for some pics.

Tools needed:

7/8" open end wrench

3/4" open end wrench

a flat head screwdriver

crescent wrench for various metric fittings somewhere between 17mm and 21mm

wire cutters

3/8" quick disconnect tool

trans oil catch pan

Parts needed:

2 - 3/8" nozzle to pipe fitting (yes you need 2 of these!) (NAPA part #05706B106)

1 - 3/8" to 3/8" male-to-male coupler (will research P/N)

1 - 3/8" pipe thread to flare thread converter (will research P/N)

1 - quick disconnect fitting (NAPA part #730-5027)

1 - 3/8" to 1/4" reducer coupling (NAPA part #3300X6X4)

2 - hose clamps (NAPA part #5051212)

1 ft of 3/8" ID trans cooler line (NAPA part #H1937)

1 or 2 quarts ATF +4 trans fluid

Total price: ~$35 for parts

Okay, here we go. The first pic is of the check valve as it sits in the stock truck in the transmission return line from the radiator. The large brass fitting contains the the check valve in question. The purpose of this check valve is to keep the Torque Converter filled with transmission fluid when the truck is off so the next time you start it, you can take off without waiting for the pump to fill the converter back up.

So why on earth would you want to remove this? Well, if you have debris in your trans fluid from normal wear and tear, a common place for it to collect is in the check valve. When this happens, the fluid flow can eventually stop and with no way to cool the internals of the transmission, it will overheat and die. A failure of this type usually results in a rebuild to the tune of at least $1200 or more.

The next pic is the connection on the radiator side:

It is typically held on with a quick connect fitting and you will need to first pop off the safety connection with a flat head screw driver. A quick disconnect tool can be used to remove the connection to the radiator, pictured here (the tool is in the middle of the pic):

I prefer the metal disconnect tools to the plastic ones as the short plastic circular tools don't really get far enough into the quick connect fitting to release the spring loaded latches. The metal ones are so much faster than wrestling with a cheapo plastic circle that gets chewed up and thrown out. Harbor Freight has them here.

Make sure you place a catch pan under the fitting before you disconnect it as trans fluid will start to drip from the radiator. You simply slide the disconnect tool over the trans cooler line on the radiator side with the flanges pointing toward the check valve and press the tool into the fitting and then pull the fitting and hose away from the radiator. Then remove the tool. The black band around the tool is actually a rubber band and assists you in closing and holding the tool around the pipe you are using it on. I suggest you leave it on the tool and just shove the disconnect tool straight down onto the radiator pipe.

Now you can remove the check valve side of the hose. The 7/8" wrench should fit on the check valve and the 3/4" should go on the silver connector on the the trans return line. The brass fitting might have corroded a bit so a shot of penetrating oil will help break it loose. When you remove the check valve tube trans fluid will drip from the trans line, so position your drip pan under there as well. I find the large 15 quart Blitz pans can cover both drips in one pan and work well.

After you remove the check valve line, turn it quick connect side down and let the trans fluid drip out. You can then take a peek in the check valve side to see the check valve inside the fitting. It's tiny and once you see it, you'll understand why it's a restriction to the system and how debris can accumulate there, especially is the tranny doesn't see a regular servicing.

Next we need to construct a new replacement hose with fittings.

First we need 1 ft of hose. Make sure it is 3/8" ID trans cooler line hose and nothing else! Trans line hose is reinforced and rated for +150PSI, any less and the hose will eventually swell and split, (probably while you're driving) and then you'll lose fluid and overheat. Here's a pic of the NAPA trans line (I bought their last 3 feet, so they gave me the box):

That hose was rated for 400PSI!

Here's a pic of the check valve side brass fittings (you can see these assembled in the quick disconnect tool pic posted earlier. It's the piece just above the tool.)

The nozzle end will go into the hose and then you'll use the band clamps to secure it. The nozzle will slide right into the hose and the band clamp will fit perfectly over the flat portion of the nozzle. The tip on the nozzle serves as a catch so that the band clamp (when tightened down) can't slide backward. The reason that you can't use just the nozzle piece is because the coupler in the truck on the check valve side is a flare thread which is different from pipe thread. The coupler in the pic is just a simple 3/8" male-to-male coupler. The large coupler was 7/8" on the outside, but the nozzle and flare pieces were 17mm (IIRC), so I just used a crescent wrench as I didn't have a larger metric wrench. RTV should not be needed if you get the fittings tight, but won't hurt if you want to use it, just use sparingly on the threads and make sure it is highly oil resistant and can take at least 250 degress.

Here's a pic of the 3 pieces that go onto the radiator side of the hose (I believe that coupler was 21mm on the outside):

And here's a close up pic of the NAPA replacement Quick Connect fitting. Notice it says DODGE/JEEP at the top:

The parts guy said he could order a quick connect with a female end that might attached directly to the 3/8" nozzle without the reducer, but I wasn't going to wait a day for a "maybe fits" part. I just bought this one and used a reducer they had in stock.

Here's the replacement hose completely assembled:

1 ft of trans tubing will probably be a little too long for the setup so you can use wire cutters to cut the trans tubing to size. Just use the old check valve unit to judge length before you cut. A razor blade won't work because the trans line is reinforced with steel mesh to keep it from expanding. Just stuff the replacement check valve fitting unit in one end of the hose, clamp it down with a hose clamp and hold it up to the old check valve line before you cut. Remember to measure twice and cut once! The new fittings will make the whole unit a little longer than the old one, so don't judge rubber tubing to rubber tubing when you cut. Throw another hose clamp on the hose before inserting the radiator side coupling. Insert radiator side coupling and tighten down the hose clamp over the fitting's nozzle end.

Tighten up the flare end onto the coupler in the truck and push the quick connect side onto the radiator. You can now remove the drip pan. Recheck all of the connections. Here's a pic of it installed:

Engage the emergency brake and start up the truck and put it in Neutral. Let the truck heat up to operating temp and check the trans fluid level on a level road or parking lot. Add more ATF +4 as needed.

It's a good idea to let the truck idle in neutral for about 10 seconds before taking off after the truck has sit for an extended length of time. This will allow the trans fluid pump to refill the Torque Converter so you don't bog and stall as you try to take off.

Enjoy your new found peace of mind.

This setup is also nice if you ever want to add an external cooler or filter to the trans return line. Just remove the hose from the fittings via the hose clamps and place the cooler or filter unit in between the two couplings and pipe the hoses into your current couplings. Just check to make sure that if there is a recommended direction of flow, you pipe it in correctly. The flow for the check valve portion we've removed is from radiator to transmission (the return line). You'll notice the flow direction is marked on the old check valve itself.

Last edited by jasonw; 05-23-2010 at 02:06 AM.