Header coatings? JET-HOT!

#11

true but when you only pay 150 for them in the first place. I figured its kinda crazy to spend that much. Not sure what the pre coated ones sell for. I decided to give the Eastwood high temp header paint a try. I figure why not give it a shot. Maybe it will hold up and I can save some people money. **** for 30 bucks a can it better hold up for a while

#15

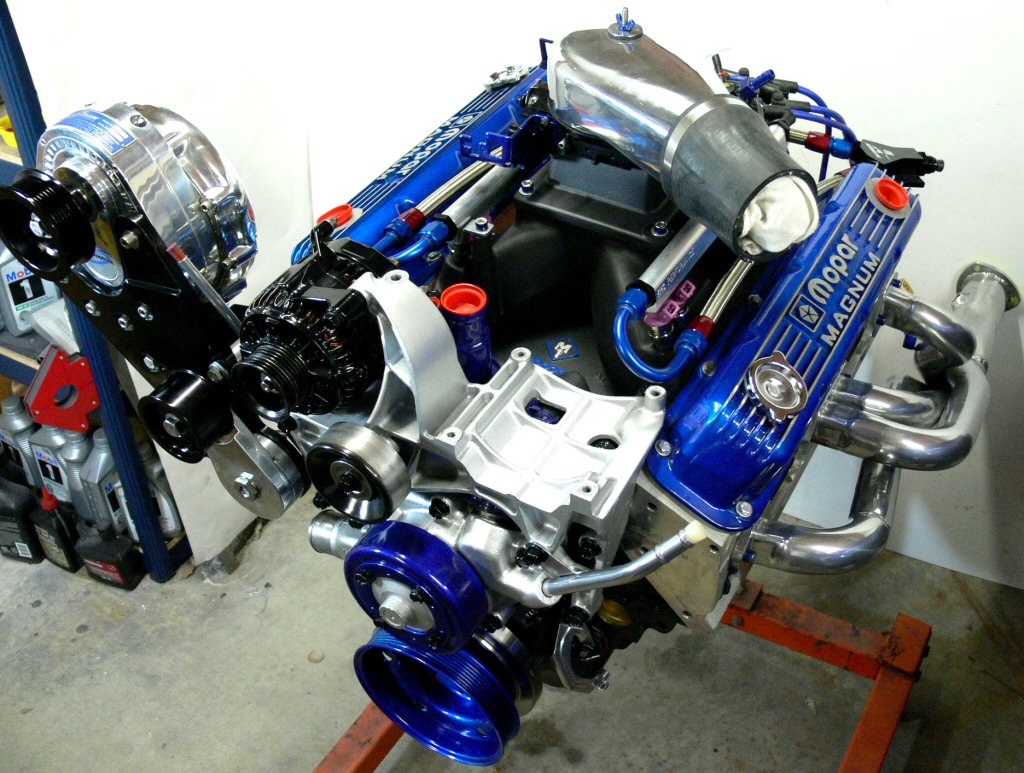

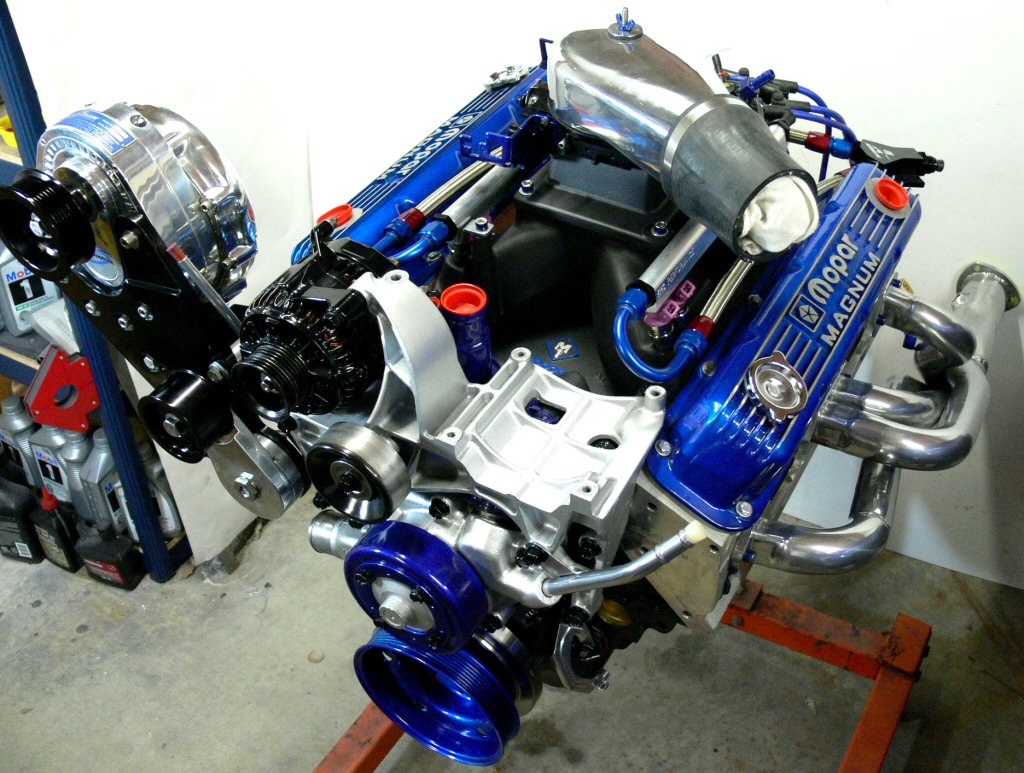

As far as the stiffy goes, yeah me too. The wife thought I was going to sleep in my garage cause I was so excited after doing the mock up to make sure everything still fit together lmao

Twisted - I was just curious about the Eastwood hi heat, its not like I will not be using it cause I have already got everything coated thats heat related with specialty powder coat.

Ram_Me - You just love showing off that beautiful engine of yours..

Daily - thanks

#17

Rocks360, were you planning on getting the new parts shipped directly to Jet Hot to be coated & then Japan or sent to home in the US?

One thing about coatings, be sure you have the right parts before coating. Found that out back in 98 when I got my valve covers, chrome diff cover & a dips stick tube coated. Dropped off all the parts as soon as I got them, didnt open the parts bags duhh, Turned out I got a 318 dipstick tube coated. No returning parts once coated

One thing about coatings, be sure you have the right parts before coating. Found that out back in 98 when I got my valve covers, chrome diff cover & a dips stick tube coated. Dropped off all the parts as soon as I got them, didnt open the parts bags duhh, Turned out I got a 318 dipstick tube coated. No returning parts once coated

#18

I ordered my Pacesetter LT hdrs painted cause I wasnt sure if they ceramic coated the inside. Was going to go with Jet Hot but shipping on all my parts (wanted other stuff done) was going to cost way too much. I went to a place up here called Fireball coatings (Ont/Cda). http://www.fireballcoatings.com/inde...id=4&Itemid=12

They blasted, added flanges, cleaned up my weld job on the 2nd o2 bung & coated ceramic inside & outside (30% under hood temps claimed) as well as got their XMC 3 stage coating on the inside also. Its suppose to further reduce underhood temps so they're 70% lower with the ceramic. My ported M1/4BBL has special heat reflecting coating on the under side & their heatsink thermal (disperses heat faster) on the top of it. My blower pistons have ceramic coated tops & moly coating on the skirts.

edit - Oh, & I detailed the M1 with ceramic blue & silver paint myself

They blasted, added flanges, cleaned up my weld job on the 2nd o2 bung & coated ceramic inside & outside (30% under hood temps claimed) as well as got their XMC 3 stage coating on the inside also. Its suppose to further reduce underhood temps so they're 70% lower with the ceramic. My ported M1/4BBL has special heat reflecting coating on the under side & their heatsink thermal (disperses heat faster) on the top of it. My blower pistons have ceramic coated tops & moly coating on the skirts.

edit - Oh, & I detailed the M1 with ceramic blue & silver paint myself