Bodywork for beginner???

#1

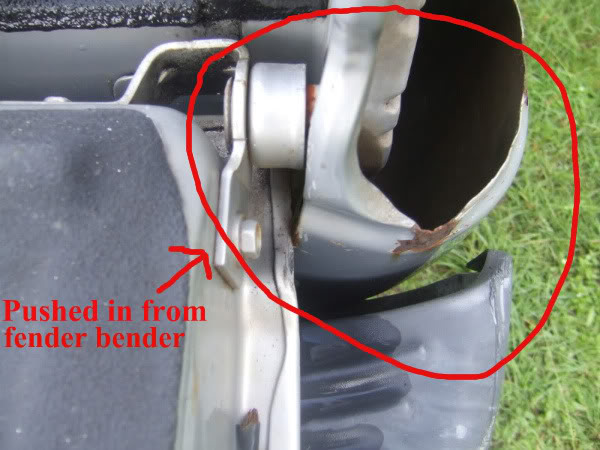

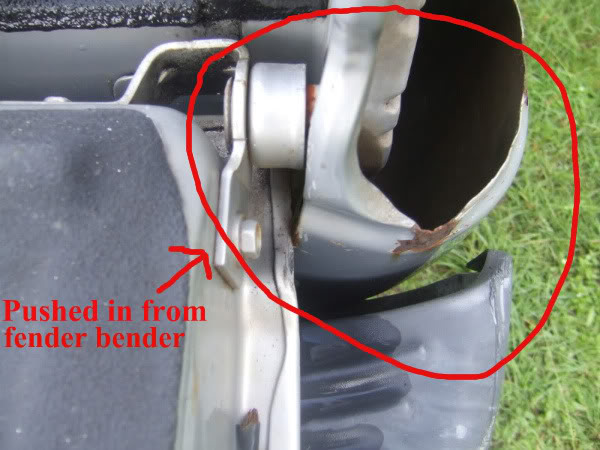

Hey guys I was wondering if you could tell me how to fix these body problems.I have some rust and would like to get rid of it.I have never done any body work and wold like to try it out.The truck was given to me by my dad and I am 18.I want to learn a bunch of stuff.Here are some pics of the damage.

#2

K im no expert by any means on body work but here is my 2 cents. for your surface rust and scratches you can just hand sand them down to bare metal or use a little pneumatic sander and it will buff them out, prime and paint. For the rust holes there is only one real proper way you have to remove the rust and get back to bare metal, probaly using a cutoff wheel on a die grinder or dremel so you can cut precise. Then you take a piece of sheel metal and cut it to fit the hole you made. Tack weld it in place and lighly hammer it to the shape you need. then weld it right up and grid it smooth. For your dents and such on your rear end you would have to pry panels out so they match the original body line, use pieces of wood or bars to get it back in the original spots then a hammer and a block of wood to get the smaller dents out. Use bondo to fill small holes or scratches sand and prime/paint.

Jake

Jake

#3

The work is not that bad for a beginner. It is posessing the TOOLS to do it all:

Pneumatic tools

Grinder

Sander

Paint gun

Plus a welding machine.

if you do not have the tools, it would be cheaper to have the work done professionally, than to buy all the tools to do it yourself. YOu will need at least a 60 gallon compressor and all the pneumatic tools listed. THat will run you about 700 just for those tools. Then a mig/tig welding machine. Not sure how much that costs but it is a lot.

--dan

Pneumatic tools

Grinder

Sander

Paint gun

Plus a welding machine.

if you do not have the tools, it would be cheaper to have the work done professionally, than to buy all the tools to do it yourself. YOu will need at least a 60 gallon compressor and all the pneumatic tools listed. THat will run you about 700 just for those tools. Then a mig/tig welding machine. Not sure how much that costs but it is a lot.

--dan

#5

#6

#7

Not really. When welding thin metal usually you do a bunch of tack welds and bounce around the panel to keep the heat down and prevent buring through. An arc welder can't really tack to well. You would have to weld short sections and hope you didn't burn through. If you did burn through you would be pretty screwed. It doesn't seem like you have a lot of welding experience so I would not suggest it.

Trending Topics

#8

#9

Forgot to mention the taillight bracket is busted so it wont sit right.

http://i92.photobucket.com/albums/l3.../Damage2-1.jpg

http://i92.photobucket.com/albums/l3.../Damage2-1.jpg

#10

I usually approach things from a different angle than most but here are my thoughts...

See if you can find that rear panel at a junkyard and see what it would cost. If too expensive, then you are suck with bending and beating and pulling. When it comes to welding, I'd look at at an oxy-acetylene torch and braze the pieces together. For the rust holes, I'd grind or sand them down and brush a little epoxy on the inside of the hole and lay some fiberglass mat on it and apply another layer of epoxy. If you can't get to the inside, cut a piece of fiberglass about four times the size of the hole, tie a string to the center of the fiberglass, slather it with epoxy and stuff it through the hole. Use the string to pull it flush with the surface.

Once it's cured, apply a thin layer of Bondo on the outside. That 1/4" rule is good unless you reinforce it with fiberglass. Bondo sands much easier than epoxy. Sand it smooth with 100 grit sand paper then 400. I'd prime it with Restoleum primer then wet sand it with 400 grit then paint it. Again, I'd use Rustoleum Professional something or other spray paint. Wet sand it with 400 grit then 1000 grit.

If you are going to use Bondo, epoxy or fiber glass, or even welding, practice a lot before you try it on your truck.

See if you can find that rear panel at a junkyard and see what it would cost. If too expensive, then you are suck with bending and beating and pulling. When it comes to welding, I'd look at at an oxy-acetylene torch and braze the pieces together. For the rust holes, I'd grind or sand them down and brush a little epoxy on the inside of the hole and lay some fiberglass mat on it and apply another layer of epoxy. If you can't get to the inside, cut a piece of fiberglass about four times the size of the hole, tie a string to the center of the fiberglass, slather it with epoxy and stuff it through the hole. Use the string to pull it flush with the surface.

Once it's cured, apply a thin layer of Bondo on the outside. That 1/4" rule is good unless you reinforce it with fiberglass. Bondo sands much easier than epoxy. Sand it smooth with 100 grit sand paper then 400. I'd prime it with Restoleum primer then wet sand it with 400 grit then paint it. Again, I'd use Rustoleum Professional something or other spray paint. Wet sand it with 400 grit then 1000 grit.

If you are going to use Bondo, epoxy or fiber glass, or even welding, practice a lot before you try it on your truck.