Help with 9.25 rear end

#31

Holy crap! I've removed and reinstalled mine a good dozen times and never broke a one. If I were you, I'd bite the bullet and pay whatever they charge at your local dealer for that part. Those bolts are nothing to go cheap on, as well as the ring gear bolts. You could try ARP and see if they have your bolts, but I would not use anything you can get at Home Depot for this project. Except maybe that wood I was talking about.

#32

Thanks, that's what I needed to hear about buying the good stuff. I didn't see a direct fit on APR's website for a 9.25", so I emailed them. I will also order their chrome moly ring gear bolts.  It crossed my mind about ordering some of APR's bolts when I started this differential upgrade.

It crossed my mind about ordering some of APR's bolts when I started this differential upgrade.

Oh, I learned the hard way that the DANG ring gear bolts are LEFT HAND THREADED!

Again, thanks for your help.

Oh, I learned the hard way that the DANG ring gear bolts are LEFT HAND THREADED!

Again, thanks for your help.

#33

OOPS! I'll admit, I did that too. I even reminded myself they were but I guess I forgot when I went to take them off. Broke two. What did you use for the ring gear this time? The ones from the kit? Regardless, like I said, I tossed those and got the bolts from the dealer. A bit pricey, but you might be able to find a set on eBay. They come up here and there, but the dealer is a guarantee. Funny story, I told my wife I was going to the dealer to pick my my ring gear bolts and she asked me what were reindeer bolts? She's cute.

#34

I used the bolts that came w/ the kit. Another reason why I'm going w/ the ARP, bec I made a little mistake... Well, may not be that bad, but I'm redoing it anyways. I should have torq'd my ring gear bolts dry, then individually, unscrew, apply loctite, then retorq. I know loctite sets in pretty quickly and R. G. bolts aren't any good after one use bec they stretch. I think I will buy a left hand 7/16 fine thread tap, to clean old loctite out of the ring before installing the ARP bolts. Do you know another way of cleaning out that mess?

#35

I use loctite red. It's not supposed to dry until it has a bit of stress on the bolts (i.e. tightened). It doesn't dry very fast otherwise. So there is no rush on getting those bolts in - it's not like epoxy. If it's still "gooey" then the bolt wasn't tighted enough for it to dry. When it does try, it can be broken up and probably just blown out with an air gun. thread in a bolt in and out a few times to loosen it up and it should just come out. Like I said, though, if it's gooey, then run with it. Also, with stock factory bolts, there's really no need for loctite as the OEM bolts have self locking heads. Piece of mind is good, but loctite does add that variable in getting the right torque on them thar bolts.

#36

Had to do some homework on the ARP studs and ring gear bolts. Called and spoke w/ a Ms."K" at ARP and was very knowledgeable about their products. Pointed me in the right direction on the stud kit (250-3004). The studs will be a tad bit longer. I shouldn't have any issue w/ the stock diff cover, even w/ the longer studs. If I do, I will upgrade to a deep 4-5 qt diff cover.

Then, I ordered a set of LH 7/16-20 .850 UHL, (230-3002), but only 10 come in a set.... , I had to order 2 extras from ARP, now will have a total of 12 ARP ring gear bolts. I also have a LH 7/16-20 tap on order. I know it may not be needed, but just want to make sure the threaded hole is completely clean (being ****, i know)

, I had to order 2 extras from ARP, now will have a total of 12 ARP ring gear bolts. I also have a LH 7/16-20 tap on order. I know it may not be needed, but just want to make sure the threaded hole is completely clean (being ****, i know)

Then, I ordered a set of LH 7/16-20 .850 UHL, (230-3002), but only 10 come in a set....

Last edited by nbrion1; 05-08-2012 at 10:02 PM.

#38

I remember finding ring gear bolts, by the time I found a kit, I had already bought from the dealer. Pain in the a$$. Well worth the wait, though. If anything, piece of mind. You don't want to have to worry about some hardware bolts hanging on for dear life under all of that stress, you know?

#39

I'm glad you were strict on me about buying the good bolts.

I know its a good investment. Picked up some ARP Ultra- torq lube today. I spoke w/ APR and instructed me:

I know its a good investment. Picked up some ARP Ultra- torq lube today. I spoke w/ APR and instructed me:

ARP Carrier main caps stud kit: Hand tight the studs, use the ARP moly lube on the washer, nut, and to torq to 110 ft/lbs in 3 step increments. Crossing patterns, 36, 72, 110. Done!

ARP Ring Gear Bolts: It is critically important to properly tighten ring gear bolts and make sure they donít loosen. This is especially important in drag cars with tire shake. Itís also a good idea to check bolt tightness on a routine basis. If you use a locking compound (like Loc-Tite), it is best to install the ring gear first without any compound, then remove the bolts one at a time, reinstalling them with the compound. Be sure and torque each bolt before going on to the next one, because the Loc-Tite sets up fast. Install and torque the bolts in an alternating or crossing pattern to distribute the load evenly around the ring gear.

Part Number: 230-3002

Application: LH 7/16-20

Ring Gear Bolt without Washer- Installation

[1] Please check the part-number(s) for your application

against the part-number(s) listed on the instruction

sheet.

[2] DO NOT USE ANY WASHERS with ARP Ring Gear

Bolts. They are designed to be installed without

them. Note: ARP will NOT be responsible for any

failures resulting from using a washer with this kit.

[3] Make sure there is an adequate chamfer around the

bolt holes on the differential to clear the radius under

the head of the bolt.

[4] Lubricate the threads of the bolt with LOCTITE 242

and the under head of the bolt with ARP ULTRATORQUE FASTENER ASSEMBLY LUBRICANT.

Then install the ring gear onto the differential and

tighten the bolts hand tight.

[5] Using an alternating or criss cross pattern, torque the

bolts to 85 ft lbs using the specified lubricants

Oh, I think the factory diff cover will be okay w/ the longer studs. I did a quick mock-up and it appeared okay.

ARP Carrier main caps stud kit: Hand tight the studs, use the ARP moly lube on the washer, nut, and to torq to 110 ft/lbs in 3 step increments. Crossing patterns, 36, 72, 110. Done!

ARP Ring Gear Bolts: It is critically important to properly tighten ring gear bolts and make sure they donít loosen. This is especially important in drag cars with tire shake. Itís also a good idea to check bolt tightness on a routine basis. If you use a locking compound (like Loc-Tite), it is best to install the ring gear first without any compound, then remove the bolts one at a time, reinstalling them with the compound. Be sure and torque each bolt before going on to the next one, because the Loc-Tite sets up fast. Install and torque the bolts in an alternating or crossing pattern to distribute the load evenly around the ring gear.

Part Number: 230-3002

Application: LH 7/16-20

Ring Gear Bolt without Washer- Installation

[1] Please check the part-number(s) for your application

against the part-number(s) listed on the instruction

sheet.

[2] DO NOT USE ANY WASHERS with ARP Ring Gear

Bolts. They are designed to be installed without

them. Note: ARP will NOT be responsible for any

failures resulting from using a washer with this kit.

[3] Make sure there is an adequate chamfer around the

bolt holes on the differential to clear the radius under

the head of the bolt.

[4] Lubricate the threads of the bolt with LOCTITE 242

and the under head of the bolt with ARP ULTRATORQUE FASTENER ASSEMBLY LUBRICANT.

Then install the ring gear onto the differential and

tighten the bolts hand tight.

[5] Using an alternating or criss cross pattern, torque the

bolts to 85 ft lbs using the specified lubricants

Oh, I think the factory diff cover will be okay w/ the longer studs. I did a quick mock-up and it appeared okay.

#40

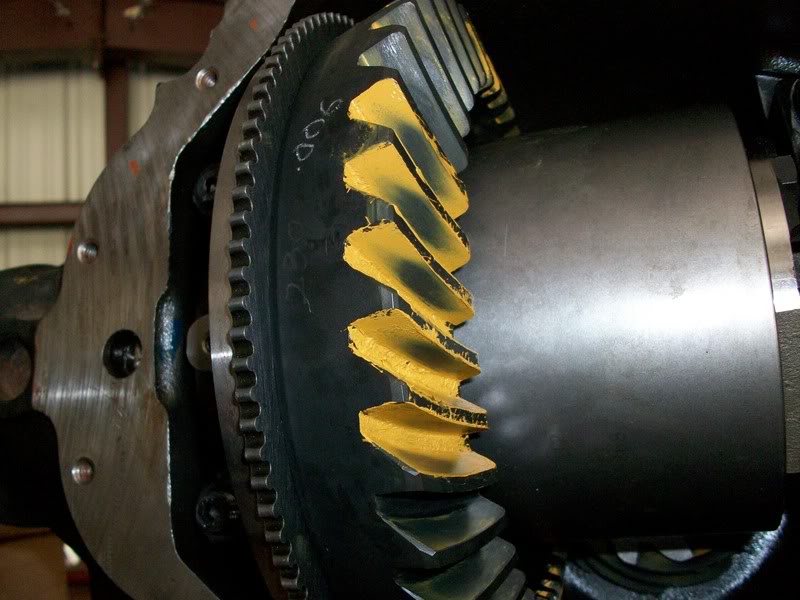

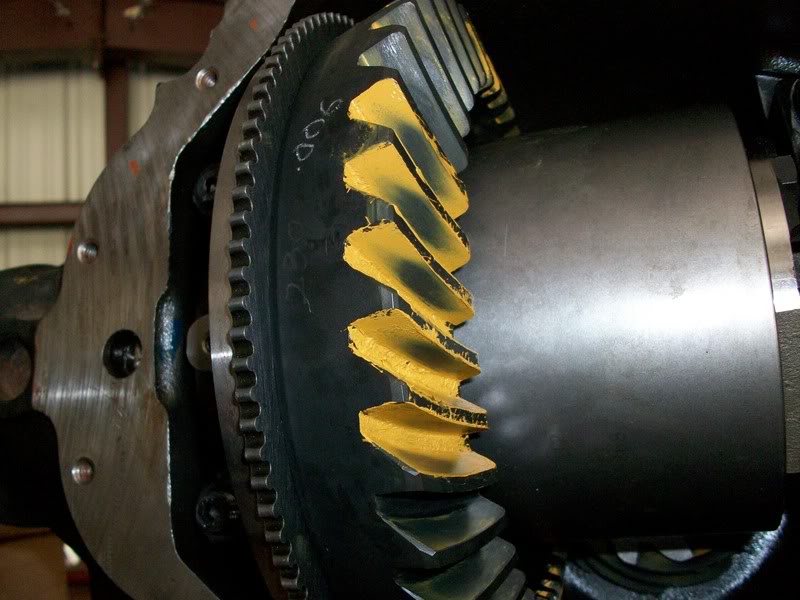

Need some help/direction. Set BL to 0.006" and stayed w/ current pinion shim.

Two things:

1) Checking rotational drag at pinion nut: clockwise (20 in-lbs) counterclockwise (24 in-lbs) and the tool is brand new. Still are in specs for NEW bearings. (what am I missing here)

2)I have a very very small play in the flange 0.003" , I feel if I would have continue to tighten the nut I would have surpassed the 25 in-lbs.

I don't understand why this picture of the FLANGE is so big I've resized it down.!! !!

Two things:

1) Checking rotational drag at pinion nut: clockwise (20 in-lbs) counterclockwise (24 in-lbs) and the tool is brand new. Still are in specs for NEW bearings. (what am I missing here)

2)I have a very very small play in the flange 0.003" , I feel if I would have continue to tighten the nut I would have surpassed the 25 in-lbs.

I don't understand why this picture of the FLANGE is so big I've resized it down.!! !!

Last edited by nbrion1; 05-16-2012 at 02:33 PM.