Loosing FP on 2001 24V

#1

This relates to my previous post about in-tank fuel pump.

I thought that was going to be the culprit but apparently not.

Truck currently has a (one month old ) Reman VP44, new 1/2" lines, did away with banjo fittings and new Lift pump. The LP is working fine alone.

I drove the truck maybe 300 miles with the above set up with no problems with a WOT fuel pressure of 16 to 17 and 18 at idle. Volume is 120gph.

I just started getting hard starts, threw a 0216 code and once truck warms up as soon as you start under a load, the pressure steadily drops down to ZERO. Let it sit for 1 minute and it builds back up.

Did I get a bad IP? I'm sending it back for warranty but is there anything else besides air, bad IP or bad lift pumps that would cause this ?

I mean ONE MONTH and it DIES. wtf.

I thought that was going to be the culprit but apparently not.

Truck currently has a (one month old ) Reman VP44, new 1/2" lines, did away with banjo fittings and new Lift pump. The LP is working fine alone.

I drove the truck maybe 300 miles with the above set up with no problems with a WOT fuel pressure of 16 to 17 and 18 at idle. Volume is 120gph.

I just started getting hard starts, threw a 0216 code and once truck warms up as soon as you start under a load, the pressure steadily drops down to ZERO. Let it sit for 1 minute and it builds back up.

Did I get a bad IP? I'm sending it back for warranty but is there anything else besides air, bad IP or bad lift pumps that would cause this ?

I mean ONE MONTH and it DIES. wtf.

#2

first things first...what kind of fuel pressure gauge are you using? mechanical? electronic?

if mechanical: using an isolator and a needle valve?

if electronic: using a needle valve or a snubber?

The reason I ask is because for years I ran a mechanical gauge with an isolator, and after 4 years my isolator went bad and would bleed off pressure looking like I was slowly losing fuel pressure...I checked the lift pump and everything thinking maybe my lift pump went bad...

well I finally put a test gauge on there and had full pressure (20psi) while my gauge was reading like 5psi..

found out the isolator was leaking on the alcohol side...

so what did I do? I eliminated the isolator and ran napa 1/8" airbrake line straight from the needle valve to the gauge. no more isolator. fuel straight to the gauge. haven't had a problem since.

if mechanical: using an isolator and a needle valve?

if electronic: using a needle valve or a snubber?

The reason I ask is because for years I ran a mechanical gauge with an isolator, and after 4 years my isolator went bad and would bleed off pressure looking like I was slowly losing fuel pressure...I checked the lift pump and everything thinking maybe my lift pump went bad...

well I finally put a test gauge on there and had full pressure (20psi) while my gauge was reading like 5psi..

found out the isolator was leaking on the alcohol side...

so what did I do? I eliminated the isolator and ran napa 1/8" airbrake line straight from the needle valve to the gauge. no more isolator. fuel straight to the gauge. haven't had a problem since.

#3

Thanks Jigabop,

I actually did think of exactly what you had a problem with after posting. It was not that. However, I feel like a total dumbass.

The problem was a totally clogged screen on the new lift pump. It was fresh. I must have accidentally dumped a bunch of sand, etc. that was sitting on top of fuel tank. I thought I was clean enough but guess not. Then I said ok, might as well pump the tank and manually clean it out.

Now I have 23psi at idle and 20psi WOT.

SO, the question is that too HIGH a pressure? lol.

I actually did think of exactly what you had a problem with after posting. It was not that. However, I feel like a total dumbass.

The problem was a totally clogged screen on the new lift pump. It was fresh. I must have accidentally dumped a bunch of sand, etc. that was sitting on top of fuel tank. I thought I was clean enough but guess not. Then I said ok, might as well pump the tank and manually clean it out.

Now I have 23psi at idle and 20psi WOT.

SO, the question is that too HIGH a pressure? lol.

#4

OK, this relates to my post. Over on the Cummins forum someone posted this about my set-up ( of Two inline fuel pumps before the IP, one in-tank the other auxilary on the frame ) What do you all think? Two others have had the same set-up as me for over 2 years with no problems.

Quote " There are 1 of two scenarios that can happen when running a stock and aftermarket in series:

1 - the truck kills the VP44 due to lack of fuel

2 - your in tank pump fails and allows free flow of fuel

However, if you were to run them in parallel then there shouldn't be a problem. As long as the pressure bypass on both pumps are equal to each other there won't be a problem. There is a negative potential side to running in series - if your stock lift pump pressure relief is set at 12 and your aftermarket is set at 20, your system will theoretically only make it to 12 before pushing fuel back through the in tank pump.

This follows the basic operating principles of flow rates in pumps. Used to use it all the time with the control HPU's I worked with. In order to run primary and secondary pumps properly you have to do the math. If the volumes are different and pressures are different, there is no way the secondary pump can properly run at its full potential - you are limited to the most fuel that the primary pump can move.

If the pumps were in series, lets say they were both running full flow - there is no way the secondary lift pump would be able to pull its 95gph since its supply is only 35gph. That being said, you system is limited to only 35gph. However, if you are not running a heavy fuel tuner then that 35gph will be more than sufficient to run the truck. " end quote

Quote " There are 1 of two scenarios that can happen when running a stock and aftermarket in series:

1 - the truck kills the VP44 due to lack of fuel

2 - your in tank pump fails and allows free flow of fuel

However, if you were to run them in parallel then there shouldn't be a problem. As long as the pressure bypass on both pumps are equal to each other there won't be a problem. There is a negative potential side to running in series - if your stock lift pump pressure relief is set at 12 and your aftermarket is set at 20, your system will theoretically only make it to 12 before pushing fuel back through the in tank pump.

This follows the basic operating principles of flow rates in pumps. Used to use it all the time with the control HPU's I worked with. In order to run primary and secondary pumps properly you have to do the math. If the volumes are different and pressures are different, there is no way the secondary pump can properly run at its full potential - you are limited to the most fuel that the primary pump can move.

If the pumps were in series, lets say they were both running full flow - there is no way the secondary lift pump would be able to pull its 95gph since its supply is only 35gph. That being said, you system is limited to only 35gph. However, if you are not running a heavy fuel tuner then that 35gph will be more than sufficient to run the truck. " end quote

#5

I know several guys running 27psi idle and they have actually reported better throttle response from the truck with the higher pressure.

not saying run as much pressure as you can, but I think between 14-25/30psi is a good safe range for the vp44...though if pressure is too high during cranking you might have a hard start scenario. but the ECM automatically runs your lift pump at 20% power during cranking to overcome that...

#6

OK, this relates to my post. Over on the Cummins forum someone posted this about my set-up ( of Two inline fuel pumps before the IP, one in-tank the other auxilary on the frame ) What do you all think? Two others have had the same set-up as me for over 2 years with no problems.

Quote " There are 1 of two scenarios that can happen when running a stock and aftermarket in series:

1 - the truck kills the VP44 due to lack of fuel

2 - your in tank pump fails and allows free flow of fuel

However, if you were to run them in parallel then there shouldn't be a problem. As long as the pressure bypass on both pumps are equal to each other there won't be a problem. There is a negative potential side to running in series - if your stock lift pump pressure relief is set at 12 and your aftermarket is set at 20, your system will theoretically only make it to 12 before pushing fuel back through the in tank pump.

This follows the basic operating principles of flow rates in pumps. Used to use it all the time with the control HPU's I worked with. In order to run primary and secondary pumps properly you have to do the math. If the volumes are different and pressures are different, there is no way the secondary pump can properly run at its full potential - you are limited to the most fuel that the primary pump can move.

If the pumps were in series, lets say they were both running full flow - there is no way the secondary lift pump would be able to pull its 95gph since its supply is only 35gph. That being said, you system is limited to only 35gph. However, if you are not running a heavy fuel tuner then that 35gph will be more than sufficient to run the truck. " end quote

Quote " There are 1 of two scenarios that can happen when running a stock and aftermarket in series:

1 - the truck kills the VP44 due to lack of fuel

2 - your in tank pump fails and allows free flow of fuel

However, if you were to run them in parallel then there shouldn't be a problem. As long as the pressure bypass on both pumps are equal to each other there won't be a problem. There is a negative potential side to running in series - if your stock lift pump pressure relief is set at 12 and your aftermarket is set at 20, your system will theoretically only make it to 12 before pushing fuel back through the in tank pump.

This follows the basic operating principles of flow rates in pumps. Used to use it all the time with the control HPU's I worked with. In order to run primary and secondary pumps properly you have to do the math. If the volumes are different and pressures are different, there is no way the secondary pump can properly run at its full potential - you are limited to the most fuel that the primary pump can move.

If the pumps were in series, lets say they were both running full flow - there is no way the secondary lift pump would be able to pull its 95gph since its supply is only 35gph. That being said, you system is limited to only 35gph. However, if you are not running a heavy fuel tuner then that 35gph will be more than sufficient to run the truck. " end quote

I used to run in-tank + holley blue in series...it does just fine till the blue pump dies due to fuel leaking past the seal since it was never meant to handle diesel fuel.

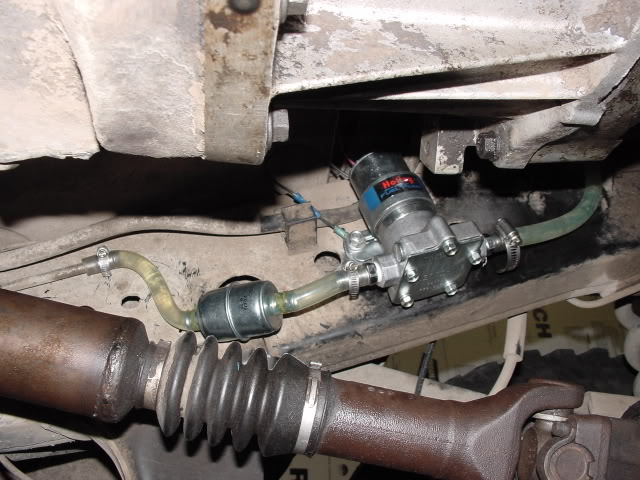

this used to be my setup:

in tank pump + pre-filter + holley blue