wheel and tire weight compare

#11

i will for sure, but it wont be soon, im just about at the limit for truck mods untill fall. i have a bunch of stuff to do to my bike before the race season starts, and then its not cheap to race it. ill have to go easy with the truck and see how i make out with it severly over geared. probly leave it right in number 1 for city driving lol. I WILL get it beefed up though. when i do ill probly do a suspension lift too  untill then we can keep brain storming about it. im going to read up on SAS

untill then we can keep brain storming about it. im going to read up on SAS

untill then we can keep brain storming about it. im going to read up on SAS

untill then we can keep brain storming about it. im going to read up on SAS

#12

sas looks to be mostly done with old ford and chev stuff(been googling my *** off) and going with leaf springs looks much easier than a 3 link setup. havent found anything with our bolt pattern yet

i think it would be easier/cheaper to modify CV axles to fit a larger unit(out of a Ram maybe) to get a bigger center section to get the big gear ratios. going to have to go measure some stuff....

edit: looks like the 97-99 Dakota that used the AMC Model 35 front diff has the option for pretty big ratios (you can go to 5.13s!). im not sure about how the strength is compared to the 7.25 or 8.25 or 9.25 though?? the ring gear is 7.562 however this might be a bolt in setup???

it also was on the 98 and 99 Durango

the Dana Spicer D44(8.5 ring gear) found on 55-02 1/2 and 3/4 ton Ram goes higher than 5.13

so this would mean the Durango 9.25 rear would be the limiting factor in getting low end power. more searching turned this up. the Dana Spicer D60 (9.75 ring gear) from the 63-02 3/4 ton and 83-95 1 ton Ram goes way higher than 5.13! (7.17).

hopefully we can find more info on the AMC diff, im doubtful the D44 would be a bolt in

i think it would be easier/cheaper to modify CV axles to fit a larger unit(out of a Ram maybe) to get a bigger center section to get the big gear ratios. going to have to go measure some stuff....

edit: looks like the 97-99 Dakota that used the AMC Model 35 front diff has the option for pretty big ratios (you can go to 5.13s!). im not sure about how the strength is compared to the 7.25 or 8.25 or 9.25 though?? the ring gear is 7.562 however this might be a bolt in setup???

it also was on the 98 and 99 Durango

the Dana Spicer D44(8.5 ring gear) found on 55-02 1/2 and 3/4 ton Ram goes higher than 5.13

so this would mean the Durango 9.25 rear would be the limiting factor in getting low end power. more searching turned this up. the Dana Spicer D60 (9.75 ring gear) from the 63-02 3/4 ton and 83-95 1 ton Ram goes way higher than 5.13! (7.17).

hopefully we can find more info on the AMC diff, im doubtful the D44 would be a bolt in

Last edited by Blue 12; 03-18-2009 at 05:10 AM.

#13

#14

#15

Only if you get something custom built. The two axles have different spline counts and are different lengths.

#16

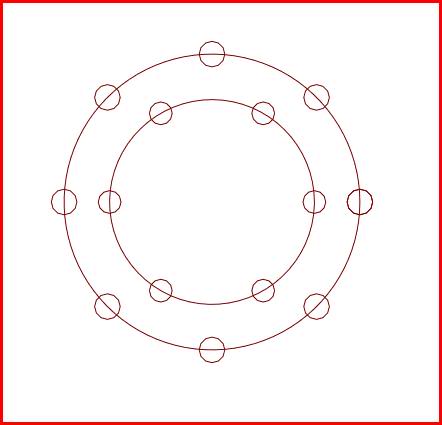

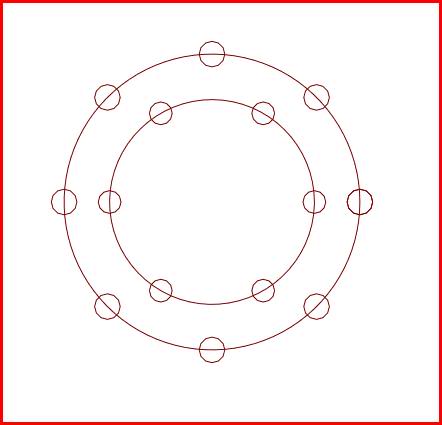

i had another idea. i would have to actually have to see the complete D60 to tell, but what if we(maybe a machine shop) just drilled the hub for the new bolt pattern? i made this drawing showing the 6x4.5 pattern and the 8x6.5 pattern in my very basic (but free) cad program

hopefully nothing would be in the way internally, and that the 16in rims would be big enough to go around the bigger hub...

hopefully nothing would be in the way internally, and that the 16in rims would be big enough to go around the bigger hub...

#17

Any machine shop with a CNC drill or milling machine should be able to do that! As long as the back side of the hub is flat (free of any welds or defects), and like you said, it needs to fit snug against the rim. I wouldn't try to do it by hand though, too much room for error. (And both my cad programs, AutoCad and Solidworks were free... great thing about being an engineering student!)

#18