Starting the build process

#371

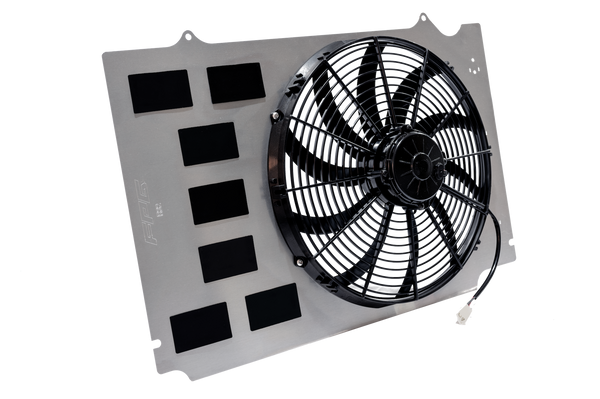

Oh OK then, so that black half-size is the AC condenser? The only other thing I can think then if sealing the shroud doesn't help is more powerful fans. Way back when I had a 96 Tahoe I replaced the mechanical with a pair of Permacool high performance fans installed in a custom stagger-stacked fan shroud, with the fans mounted to the back of the shroud and a ring around each fan to enclose the blades. Admittedly I wasn't running a supercharger, but those fans kept the Tahoe cool on the hottest days without ever hitting max while using a Delta Current Control high power fan controller. Beyond that, vents in the hood to give the air a place to go.

What are you using for a gas tank? Assuming it's behind the rear diff. This is something I'll need to do with mine.

What are you using for a gas tank? Assuming it's behind the rear diff. This is something I'll need to do with mine.

The hood has 2" spacers on the hinges to clear the air hat, eventually it'll get a 3" cowl hood.

Yea, fuel tank is in the very back. I chose to keep the tire carrier and make fit, hindsight I would have cut the carrier out and boxed it with square tube. I took a standard production tank and had a sump welded on.

Got the oil system finished tonight. Switched from a 51085 to a 51773 oil filter; That, the 19 row cooler, and 58" of 10AN oil line should add about 1-1.5 quarts to the system.

Going to drill the intake manifold tomorrow.

The distributor ho

le is 2"; One of those cheap expanding freeze plugs fit nice and perfect (dorman 02607).

I took an intake manifold gasket to get a rough idea of where the water pockets are. Then found a guy onlind that's already drilled his manifold, asked for hole dimensions. He said 1" from the top and 1.5" from the back for both sides.

Tomorrow we shall see how close that is. Silver sharpie is the water pocket, black sharpie dots are dimensional intersects.

https://photos.app.goo.gl/hsYQpn1cCwXxjkUE8

https://photos.app.goo.gl/2SwMgAqvSyM8VT7dA

https://photos.app.goo.gl/PkYawUDmTKr2HZda7

https://photos.app.goo.gl/yoNZEYpjd4LLBny88

https://photos.app.goo.gl/HuWYBoueC8ZQAwQu9

https://photos.app.goo.gl/WWnpxZKVR5V4SddU9

https://photos.app.goo.gl/8m5aM2a1k1zYbXps8

The following users liked this post:

LIZZRD (09-16-2021)

#372

#373

I knew I hadn't updated this thread in a while, but thought I had posted RMRW results at least. Oops!

RMRW runs in the Colorado and Kansas region every summer for the last 10 or so years. Last year they added a second event in September for the Kansas-Oklahoma-Texas region.

Finished the week 20th in class. Logged a touch over 1,000 miles while racing at 4 tracks in 5 days.

Day 1 - Oklahoma City, OK - 13.276

Day 2 - Dallas, TX - 13.124

Day 3 - Tulsa, OK - 13.121

Day 4 - Arkansas City, KS - 13.70 (track was ****)

Day 5 - Oklahoma City - 13.366

5-Day average: 13.3174 (good for 20th place on a 13.0 index)

I made a bonsai run at the very end, went 11.956 @ 114.05 at 8.5 pounds of boost. Truck weighs 4400 pounds with me in it. Empty weights are 2470 front, 1740 rear.

0060': 1.785

0330': 4.980

0660': 7.678 @ 91.11

1000': 9.998

1320': 11.956 @ 114.05

Once it came home, it sat for about a month as we had 4 NHRA races with the dragster in 3 weeks.

Then a few changes were made:

Traction bars

Re-stalled the converter a little tighter

Changed low gear from 1.80 to 1.98

And went to the track last weekend.

060': 1.6768

330': 4.7423

660': 7.3286 @ 95.18

I picked up 3 tenths and 4 MPH to the 1/8 mile.

It was bitter cold and wet - 62 degrees ambient, 75% humidity (incidentally, 75 grains), 1700 feet DA.

The gear change made a huge difference. Not sure if the converter change did anything at all.

Taking these 6 year old DOT radials off and putting a 28x9 slick on. Gonna try to go back out December 4th, weather permitting.

Even on the crappy old tires, it's lifting the left front tire off the ground for just a moment. But initial traction isn't happening. Hopefully the slicks fix that.

Also need to adjust the traction bars significantly.

So now I have a set of 28x9 Pro Bracket Radials mounted on OE 15x8 wheels, and I adjusted the traction bars.

I need to work on:

Mount the water-methanol injection system pump

Move the data logger and wideband to a rocker switch instead of ignition

Move the primary battery

Add a second battery

Adjust the band

Make the front loop crossmember

Make the front loop transmission tie

Make the front loop attachment points

Make the exhaust tie strap

I want to test on December 4th or 5th ideally. Maybe not with all the changes fixed, but start working that direction.

RMRW runs in the Colorado and Kansas region every summer for the last 10 or so years. Last year they added a second event in September for the Kansas-Oklahoma-Texas region.

Finished the week 20th in class. Logged a touch over 1,000 miles while racing at 4 tracks in 5 days.

Day 1 - Oklahoma City, OK - 13.276

Day 2 - Dallas, TX - 13.124

Day 3 - Tulsa, OK - 13.121

Day 4 - Arkansas City, KS - 13.70 (track was ****)

Day 5 - Oklahoma City - 13.366

5-Day average: 13.3174 (good for 20th place on a 13.0 index)

I made a bonsai run at the very end, went 11.956 @ 114.05 at 8.5 pounds of boost. Truck weighs 4400 pounds with me in it. Empty weights are 2470 front, 1740 rear.

0060': 1.785

0330': 4.980

0660': 7.678 @ 91.11

1000': 9.998

1320': 11.956 @ 114.05

Once it came home, it sat for about a month as we had 4 NHRA races with the dragster in 3 weeks.

Then a few changes were made:

Traction bars

Re-stalled the converter a little tighter

Changed low gear from 1.80 to 1.98

And went to the track last weekend.

060': 1.6768

330': 4.7423

660': 7.3286 @ 95.18

I picked up 3 tenths and 4 MPH to the 1/8 mile.

It was bitter cold and wet - 62 degrees ambient, 75% humidity (incidentally, 75 grains), 1700 feet DA.

The gear change made a huge difference. Not sure if the converter change did anything at all.

Taking these 6 year old DOT radials off and putting a 28x9 slick on. Gonna try to go back out December 4th, weather permitting.

Even on the crappy old tires, it's lifting the left front tire off the ground for just a moment. But initial traction isn't happening. Hopefully the slicks fix that.

Also need to adjust the traction bars significantly.

So now I have a set of 28x9 Pro Bracket Radials mounted on OE 15x8 wheels, and I adjusted the traction bars.

I need to work on:

Mount the water-methanol injection system pump

Move the data logger and wideband to a rocker switch instead of ignition

Move the primary battery

Add a second battery

Adjust the band

Make the front loop crossmember

Make the front loop transmission tie

Make the front loop attachment points

Make the exhaust tie strap

I want to test on December 4th or 5th ideally. Maybe not with all the changes fixed, but start working that direction.

#374

Been crawling around under the truck this week. Got the front driveshaft loop all done and driveshaft back in.

Figured out how to run the battery cables for the combined adding a battery & moving the existing battery. Also looked at my anchoring options.

I have a general idea for where to put the methanol injection pump, on the carrier bearing crossmember. Going to put the tank over/in front of the left rear fender.

As much as I really want the air compressor to be behind the axle, I am not sure it will be feasible. I found out the Viair compressors are not rated for "wet duty", so I am apprehensive to put it under the right rear bed corner like I was going to. I'd have to make a pretty big shield to keep it from getting coated in debris and spray. The entire back of the truck already has a layer of burnout rubber. It's also supposed to be mounted upright and in a well ventilated place.

My second thought was to mount it to the shock crossmember, but there's not really enough room for that without adding alot of structure.

So i may just put the compressor and tank where the battery is now. The compressor is 11 pounds, figure the tank is 4, call it 15 total. The battery is 38 pounds. So I'll still be adding 38 pounds to the left rear and moving 23 pounds behind the right rear. I can put both up high and leave the bed clear for putting supplies under. Also have to remember that I'll likely have roll cage bars going through the front of the bed, too.

I need to move the logger and wideband over to a rocker switch and make the tiebar for the exhaust.

Figured out how to run the battery cables for the combined adding a battery & moving the existing battery. Also looked at my anchoring options.

I have a general idea for where to put the methanol injection pump, on the carrier bearing crossmember. Going to put the tank over/in front of the left rear fender.

As much as I really want the air compressor to be behind the axle, I am not sure it will be feasible. I found out the Viair compressors are not rated for "wet duty", so I am apprehensive to put it under the right rear bed corner like I was going to. I'd have to make a pretty big shield to keep it from getting coated in debris and spray. The entire back of the truck already has a layer of burnout rubber. It's also supposed to be mounted upright and in a well ventilated place.

My second thought was to mount it to the shock crossmember, but there's not really enough room for that without adding alot of structure.

So i may just put the compressor and tank where the battery is now. The compressor is 11 pounds, figure the tank is 4, call it 15 total. The battery is 38 pounds. So I'll still be adding 38 pounds to the left rear and moving 23 pounds behind the right rear. I can put both up high and leave the bed clear for putting supplies under. Also have to remember that I'll likely have roll cage bars going through the front of the bed, too.

I need to move the logger and wideband over to a rocker switch and make the tiebar for the exhaust.

#375

I did not read thru the thread but was scanning thru the photo's and noticed the fan shroud... If the dak is going to see daily driving, next time you have the fans out put a divider between the shrouds and use automotive trim on the edge up against the radiator core. while testing the volvo fans for the Ram I found that if there is no divider, the fans work against each other. Dividing them forces each fan to pull across the core area on its side of the divider. I had a setup (documented over on cumminsforum.com) to test the flow of various fans, the volvo's won for size and flow so I went with 2 of them as on high I was getting something like 3700 cfm. I was expecting something around 7k when I tested 2 at the same time but was surprised to only get something like 4500.

The following users liked this post:

magnethead (12-02-2021)

#376

I did not read thru the thread but was scanning thru the photo's and noticed the fan shroud... If the dak is going to see daily driving, next time you have the fans out put a divider between the shrouds and use automotive trim on the edge up against the radiator core. while testing the volvo fans for the Ram I found that if there is no divider, the fans work against each other. Dividing them forces each fan to pull across the core area on its side of the divider. I had a setup (documented over on cumminsforum.com) to test the flow of various fans, the volvo's won for size and flow so I went with 2 of them as on high I was getting something like 3700 cfm. I was expecting something around 7k when I tested 2 at the same time but was surprised to only get something like 4500.

I need to work on:

Mount the water-methanol injection system pump

Move the primary battery

Add a second battery

Adjust the band

Make the front loop transmission tie

Make the front loop attachment points

Make the exhaust tie strap

Locate two camera mounting points

Need to adjust the band tomorrow night before putting it on the trailer.

Otherwise, ready for Saturday.

Last edited by magnethead; 12-02-2021 at 11:58 PM.

#377

The data on the fans is here... https://www.cumminsforum.com/threads...#post-19521922 the quoted text at the bottom is where the data is for the dual fan setup.

Volvo 850 MY 1997

High Speed data

3349 CFM @ 12.3V/27.3A

Measurement box = 12x12", Volume = corrected 138.0 square inches (correction for measurement probe).

Low speed data

2695 CFM @ 12.8V/13.8A

These 2 tests are no good... fans fight against each other. turned on 1 fan and the other fan spins. Pulled the test duct and the other fan stops.

tried to measure around perimeter and there is a lot of turbulence.Dual volvo fan test

Hi speed test, 50A charger hooked up, same 12x12" test duct.

4536 CFM @ 12.1V/48.9A

Dual volvo fan test

Lo speed test

3637 CFM @ 12.3V/26.2A

High Speed data

3349 CFM @ 12.3V/27.3A

Measurement box = 12x12", Volume = corrected 138.0 square inches (correction for measurement probe).

Low speed data

2695 CFM @ 12.8V/13.8A

These 2 tests are no good... fans fight against each other. turned on 1 fan and the other fan spins. Pulled the test duct and the other fan stops.

tried to measure around perimeter and there is a lot of turbulence.Dual volvo fan test

Hi speed test, 50A charger hooked up, same 12x12" test duct.

4536 CFM @ 12.1V/48.9A

Dual volvo fan test

Lo speed test

3637 CFM @ 12.3V/26.2A

#378

Opening the sides is not a good idea. Air, like water, will flow where it's easiest. It's a lot easier for air to be drawn through the rather large side openings that it is to draw through the radiator and other coolers. The next issue I see is once the air does get through the radiator, the extra gear you've installed gives it nowhere to go.

I would suggest blocking the sides of the shroud, and if it needs more airflow at speed install flaps that allow air to push out of the shroud, but not allow the fans to draw air back through the flaps. If this can be done on the Dodge you'll gain a ton of room for a larger shroud. If there's any room at all to do so, move the fans further from the radiator. In my experience, the shroud and fans need to be at least 2 inches from the radiator in order to allow the fans to draw across the entire radiator. I'd also suggest installing vents in the hood to allow air a place to escape.

It would take some major work because of how the Dodge is designed, but over in the S10 world they move the radiator in front of the rad support in order to make more room for installing a V8. It might also be beneficial to move the trans cooler to somewhere other than in front of the radiator. There is plenty of room under the truck alongside the trans to install one, and an electric fan can be mounted to keep it cool.

I would suggest blocking the sides of the shroud, and if it needs more airflow at speed install flaps that allow air to push out of the shroud, but not allow the fans to draw air back through the flaps. If this can be done on the Dodge you'll gain a ton of room for a larger shroud. If there's any room at all to do so, move the fans further from the radiator. In my experience, the shroud and fans need to be at least 2 inches from the radiator in order to allow the fans to draw across the entire radiator. I'd also suggest installing vents in the hood to allow air a place to escape.

It would take some major work because of how the Dodge is designed, but over in the S10 world they move the radiator in front of the rad support in order to make more room for installing a V8. It might also be beneficial to move the trans cooler to somewhere other than in front of the radiator. There is plenty of room under the truck alongside the trans to install one, and an electric fan can be mounted to keep it cool.

These are the guys you need to put on the shroud... https://www.summitracing.com/parts/spu-ix-30130012

Seal up the sides, divide the shroud between the fans,insert those flaps into the shroud. IIRC reduce the pressure on the back side of the radiator to increase effeciency of the setup... IIRC...

I spent part of the summer working on the aero on the ram and learned a ton... example, the bed seals on the sides of the bed, there are none. So I experimented and added them the entire depth of the bed, from the bed rail to the bottom of the bed. End result was loosing speed down some fairly steep hills. (this was back in 2018). The fix was to tape up the opening to the bumper as I thought it was acting like a parachute. Ended up stripping all that off at some point. This year I went back to it and found I got a good reduction in drag by putting the seal just down to the body line so the attached airflow only affects the upper part of the bed, just above the bumper. The result was noticeably better coasting down certain hills on the way to work. Ultimately I added 1.5 mpg between those and a tune change. Was getting 22.0~22.2 consistently before the 2 changes, jumped to 23.5~23.6. Ended up with ~12 tanks in the 23+ range.

Last edited by steve05ram360; 12-03-2021 at 10:31 AM.

#379

The data on the fans is here... https://www.cumminsforum.com/threads...#post-19521922 the quoted text at the bottom is where the data is for the dual fan setup.

#380

Talked to the fab guy that did my intercooler today. He's going to build a coolant expansion tank for me, so I can solve the cooling issue I have properly. (OK, not perfectly properly, but way better than it is now).

Went out to test and tune during a bracket race on Saturday. Entered No-Box (Transbrake) and Sportsman (Footbrake). Apparently it was my night, because I did everything possible wrong, and still kept going rounds in Sportsman.

TT#1 for both classes was on Tune Revision #009. The truck was slower than expected, so I go to put Tune #008 back in for TT #2 of both classes. Dakota battery is dead, left the electric water pump on. Go to jump it off the ram, and the Ram's battery is dead from running the power inverter for my laptop to charge. Borrowed the battery charger from the friend i was parked next to to get the Dakota fired, drove it around then was able to put Tune #008 in it. In doing so, it got hot again. At this point they called No-Box to the staging lanes. I left it running in the staging lanes, making it even hotter, and by the time i'm at the front, they shut me off because the overflow tank is blowing coolant out it's vent.

Borrowed a screw driver there under the bridge, grabbed a bottle from a trash can, and emptied the overflow tank on the spot. Fired it back up, made the run as last car in class, then came right back around to be last pair of sportsman (only 5 pairs). IT was REALLY hot now, even with WP and fans running. By the time I got parked, the windshield was fogging from the heat differential. OBD logging shows it hit 110C/230F. It's a 20 pound system (227*), so i was right on the edge of steaming.

It slowed down even more, the heat not helping, so I put Tune #009 back in and left it in for the night.

My reaction times ranged from unspeakaby/embarrassingly horrible, to 0.008.

I lost first round of No-Box, bought back for the test run, lost there.

Sportsman Round 1 I was terrible on the tree, but the other car took 7 tenths of stripe to got 2 tenths under the dial while I dropped when i knew I wasn't getting there (7.92 on a 7.50). Shouldn't have got the win, but they gave it to me.

Note: 4 of the 5 losing cars bought back in, taking the field from 10 to 9 cars for second round.

Sportsman Round 2 I was 0.008 on the tree to the other guy's .003 red. I was almost 2 tenths slow from the dial (7.68 on a 7.50). Shouldn't have got the win, but they gave it to me.

Sportsman Round 3 I was .045 on the tree to their .084, but they went into tire spin immediately. I knew I was fast and needed to shed ET, around 500' I got on the binders hard enough to unload the rear tires and it start to try to wag on me. Went through the stripe really unstable at a whole 73 MPH - I shed 18 MPH to go 7.66 on a 7.65 dial. Shouldn't have won that one, but I'd rather be lucky than good. But being good helps. It was on a 7.5x pass.

Sportsman Round 4 I was terrible on the tree again, but the other guy was .020 red. I went out the back door, 7.45 on a 7.50 dial. I should have been toast, but they gave it to me.

Sportsman Final Round I am terrible on the tree again, but my opponent goes .030 red. I run it out the back door, 7.46 on a 7.50 dial. I should have been toast, but they gave it to me.

It was just my night. I think the truck is simply so loud that it throws off the opponent and they go red. That's the only excuse I can think of to have 3 red lights in 5 rounds, and the other 2 were simply the other driver doing a bad job with otherwise winnable rounds.

https://photos.app.goo.gl/ifPCH35nYHuJnu8C6

https://photos.app.goo.gl/mmezyncDc66QTDUt6

https://photos.app.goo.gl/6vchdJcYZ4AdCkZz9

https://photos.app.goo.gl/nPQBJWDiTfvnNBZL8

https://photos.app.goo.gl/dBHf2Yb4D5kuBFAh7

Went out to test and tune during a bracket race on Saturday. Entered No-Box (Transbrake) and Sportsman (Footbrake). Apparently it was my night, because I did everything possible wrong, and still kept going rounds in Sportsman.

TT#1 for both classes was on Tune Revision #009. The truck was slower than expected, so I go to put Tune #008 back in for TT #2 of both classes. Dakota battery is dead, left the electric water pump on. Go to jump it off the ram, and the Ram's battery is dead from running the power inverter for my laptop to charge. Borrowed the battery charger from the friend i was parked next to to get the Dakota fired, drove it around then was able to put Tune #008 in it. In doing so, it got hot again. At this point they called No-Box to the staging lanes. I left it running in the staging lanes, making it even hotter, and by the time i'm at the front, they shut me off because the overflow tank is blowing coolant out it's vent.

Borrowed a screw driver there under the bridge, grabbed a bottle from a trash can, and emptied the overflow tank on the spot. Fired it back up, made the run as last car in class, then came right back around to be last pair of sportsman (only 5 pairs). IT was REALLY hot now, even with WP and fans running. By the time I got parked, the windshield was fogging from the heat differential. OBD logging shows it hit 110C/230F. It's a 20 pound system (227*), so i was right on the edge of steaming.

It slowed down even more, the heat not helping, so I put Tune #009 back in and left it in for the night.

My reaction times ranged from unspeakaby/embarrassingly horrible, to 0.008.

I lost first round of No-Box, bought back for the test run, lost there.

Sportsman Round 1 I was terrible on the tree, but the other car took 7 tenths of stripe to got 2 tenths under the dial while I dropped when i knew I wasn't getting there (7.92 on a 7.50). Shouldn't have got the win, but they gave it to me.

Note: 4 of the 5 losing cars bought back in, taking the field from 10 to 9 cars for second round.

Sportsman Round 2 I was 0.008 on the tree to the other guy's .003 red. I was almost 2 tenths slow from the dial (7.68 on a 7.50). Shouldn't have got the win, but they gave it to me.

Sportsman Round 3 I was .045 on the tree to their .084, but they went into tire spin immediately. I knew I was fast and needed to shed ET, around 500' I got on the binders hard enough to unload the rear tires and it start to try to wag on me. Went through the stripe really unstable at a whole 73 MPH - I shed 18 MPH to go 7.66 on a 7.65 dial. Shouldn't have won that one, but I'd rather be lucky than good. But being good helps. It was on a 7.5x pass.

Sportsman Round 4 I was terrible on the tree again, but the other guy was .020 red. I went out the back door, 7.45 on a 7.50 dial. I should have been toast, but they gave it to me.

Sportsman Final Round I am terrible on the tree again, but my opponent goes .030 red. I run it out the back door, 7.46 on a 7.50 dial. I should have been toast, but they gave it to me.

It was just my night. I think the truck is simply so loud that it throws off the opponent and they go red. That's the only excuse I can think of to have 3 red lights in 5 rounds, and the other 2 were simply the other driver doing a bad job with otherwise winnable rounds.

https://photos.app.goo.gl/ifPCH35nYHuJnu8C6

https://photos.app.goo.gl/mmezyncDc66QTDUt6

https://photos.app.goo.gl/6vchdJcYZ4AdCkZz9

https://photos.app.goo.gl/nPQBJWDiTfvnNBZL8

https://photos.app.goo.gl/dBHf2Yb4D5kuBFAh7