NV3500 questions

#51

#53

#54

yep. i have no problems cutting that out either. my jeep never had ac and i bypassed the heater when i did the v8. i even took out the vent controls to put in a switch plate. all they ever did was blow hot dirt on me anyway. now i use them as my reverse air intake. i ran my intake into the cowl and put the filter in there. and then blocked off the cowl vent. so my engine pulls it's air backwards through the air vents in the cab area.

as shown here:

as shown here:

#55

#57

hey, these fell off last night... is this normal?

in all seriousness when i bought this transmission i was aware of the all too common 5th gear problem that nv4500's are plagued by, but since mine was a gasser trans and not from a diesel and because i could shift into 5th gear, i never looked any closer than that. then last night while i was under the jeep working, i noticed something behind the seal, it looks like a thrust washer. and then it hit me. it was my 5th gear nut. son of a bitch.

so i took off the tailshaft housing to inspect the damage, and btw, i'd like to hang who ever thought it was a good idea to use 12pt 10mm bolts for this. and thankfully the damage is limited to only the nut.

the threads on the shaft are fine, and the splines on the gear and shaft are also fine. so i am lucky enough to get to replace the nut and be okay.

but now i have some questions.

1st and foremost, which nut is the best nut to buy? my shaft does not have a groove for a keyed lock washer so that design and the crimped design are out. does that leave me with a set screw lock nut? should i get the one with the brass pads? or without?

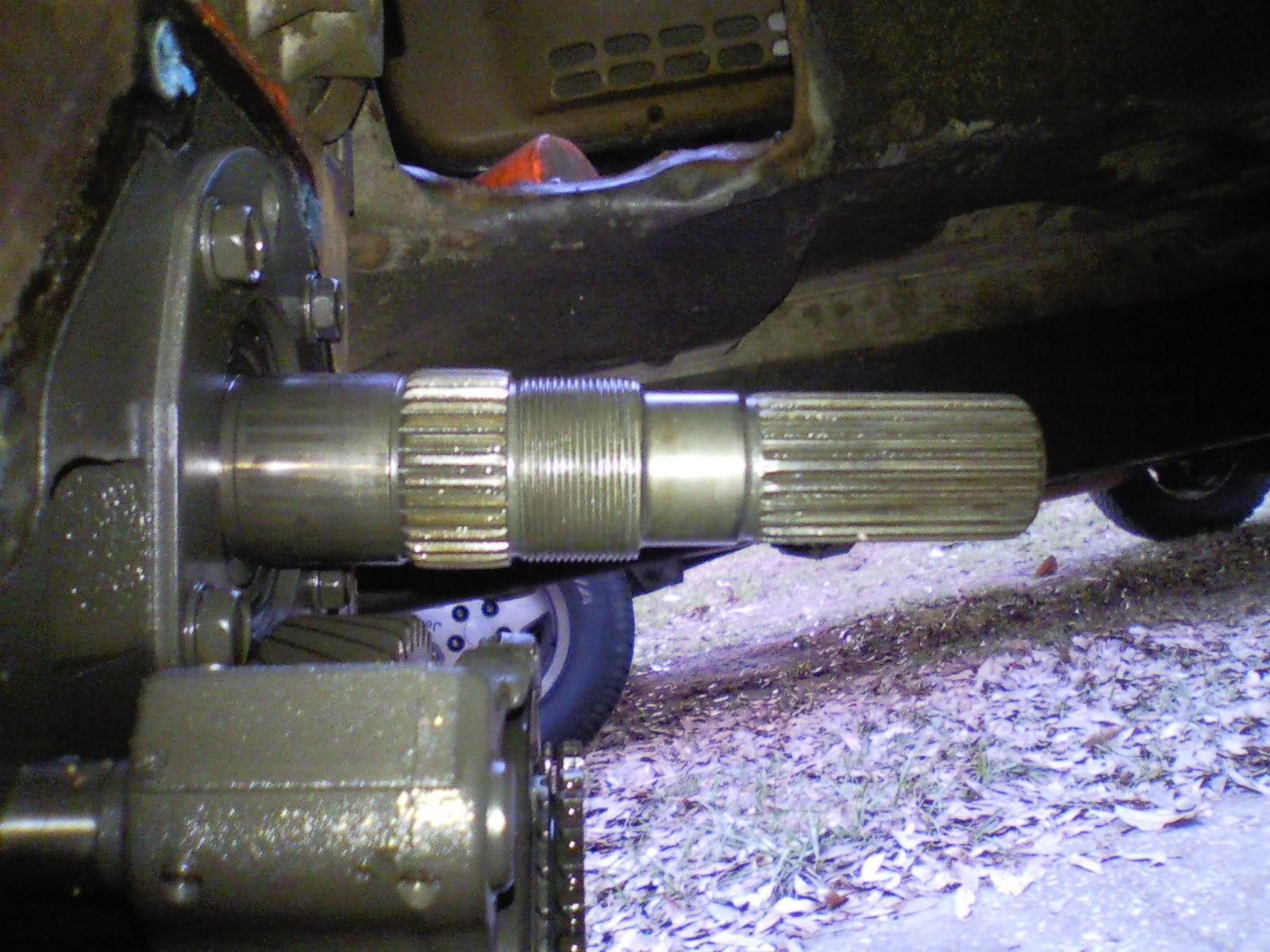

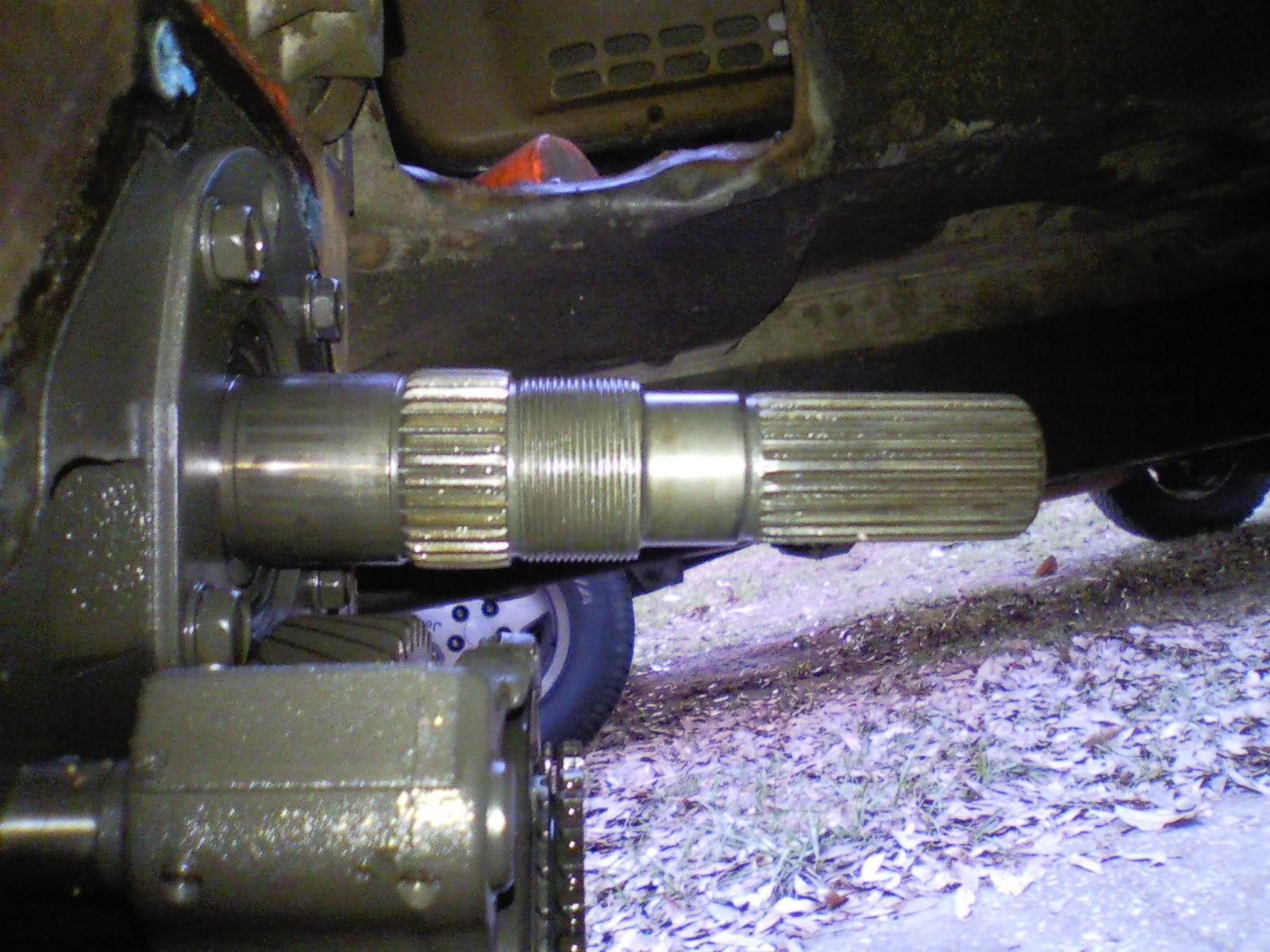

and now the unpopular question. i have heard a lot of success with tack welding the nut in place. the only people that say don't do it are the people trying to sell a product. and i agree that you should not do it to the 29 or 32 spline versions of this trans because the welded area becomes an area of significant weakness. but the 23 spline version necks down a lot and i believe if the amps and heat are kept to a minimum that the HAZ of the welds would not penetrate deep enough to create a new weakest link in the shaft. you can see the neck downs here.

it gets it's smallest right before the splines on the end which is where the most stress is anyway. and the threaded section is pretty thick. anyway, i'm not a master in metallurgy, but i think a few little tiny spot welds aren't going to make the thick threaded section weaker than the neck-down before the splines so in theory it should be ok because the shaft will still be as torque-capable as it was from the factory. the only mainshafts i've been able to find info on them breaking was in a hot rod diesel and usually had the lock washer groove in the threads.

i may save welding for the future if the nut ever backs off again. i haven't decided that yet. but i do think it's a viable option that has been quite successful for several others that do what i intend to do with it. (jeeps offroad etc...)

also, who ever designed this this way is a moron.

the splined section that drives the gear is completely not inline with the torque being applied to it. no wonder these things wobble and back off all the time. what a terrible lack of common sense that was.

in all seriousness when i bought this transmission i was aware of the all too common 5th gear problem that nv4500's are plagued by, but since mine was a gasser trans and not from a diesel and because i could shift into 5th gear, i never looked any closer than that. then last night while i was under the jeep working, i noticed something behind the seal, it looks like a thrust washer. and then it hit me. it was my 5th gear nut. son of a bitch.

so i took off the tailshaft housing to inspect the damage, and btw, i'd like to hang who ever thought it was a good idea to use 12pt 10mm bolts for this. and thankfully the damage is limited to only the nut.

the threads on the shaft are fine, and the splines on the gear and shaft are also fine. so i am lucky enough to get to replace the nut and be okay.

but now i have some questions.

1st and foremost, which nut is the best nut to buy? my shaft does not have a groove for a keyed lock washer so that design and the crimped design are out. does that leave me with a set screw lock nut? should i get the one with the brass pads? or without?

and now the unpopular question. i have heard a lot of success with tack welding the nut in place. the only people that say don't do it are the people trying to sell a product. and i agree that you should not do it to the 29 or 32 spline versions of this trans because the welded area becomes an area of significant weakness. but the 23 spline version necks down a lot and i believe if the amps and heat are kept to a minimum that the HAZ of the welds would not penetrate deep enough to create a new weakest link in the shaft. you can see the neck downs here.

it gets it's smallest right before the splines on the end which is where the most stress is anyway. and the threaded section is pretty thick. anyway, i'm not a master in metallurgy, but i think a few little tiny spot welds aren't going to make the thick threaded section weaker than the neck-down before the splines so in theory it should be ok because the shaft will still be as torque-capable as it was from the factory. the only mainshafts i've been able to find info on them breaking was in a hot rod diesel and usually had the lock washer groove in the threads.

i may save welding for the future if the nut ever backs off again. i haven't decided that yet. but i do think it's a viable option that has been quite successful for several others that do what i intend to do with it. (jeeps offroad etc...)

also, who ever designed this this way is a moron.

the splined section that drives the gear is completely not inline with the torque being applied to it. no wonder these things wobble and back off all the time. what a terrible lack of common sense that was.

#58

#59