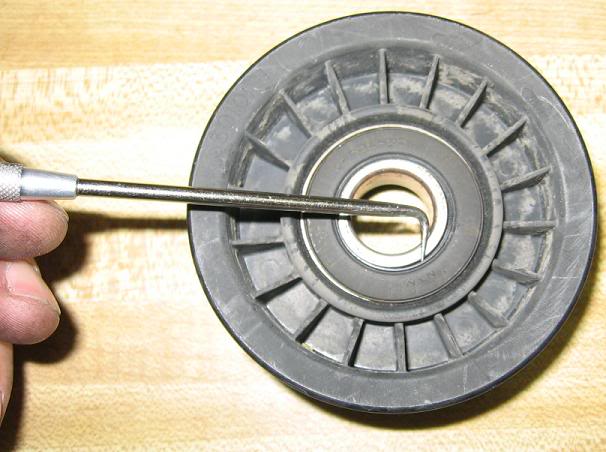

greased the idler pulley

#1

#7

Trending Topics

#8

Hi Speed grease is formulated for work in Hi-Speed bearings and usually has a higher than normal heat break down than regular. Also it lubricates better in these applications. Even wheel bearing for disk brake has a higher than normal heat range. Now regular hub/wheel bearing grease does not have a high enough heat range because of the heat from disk brake applications.

There is specifications listed on the back of the grease bottle. Ones like HS (hi-speed) EX (extreme pressure) MN (marine) MP (multi-purpose)

Check this out! Timken grease for their bearings which sould be the one your using or close to it.

http://www.alliedbearings.com/new_pr...en_grease.html

There are 2 basic greases you want in your arsenal:

1. Wheel Bearing Grease for disk brake applications. (Muti Grease) With specifications for your intended use.

2. Moly. Engine building and sealing and other work.

There is specifications listed on the back of the grease bottle. Ones like HS (hi-speed) EX (extreme pressure) MN (marine) MP (multi-purpose)

Check this out! Timken grease for their bearings which sould be the one your using or close to it.

http://www.alliedbearings.com/new_pr...en_grease.html

There are 2 basic greases you want in your arsenal:

1. Wheel Bearing Grease for disk brake applications. (Muti Grease) With specifications for your intended use.

2. Moly. Engine building and sealing and other work.

Last edited by hydrashocker; 06-11-2009 at 03:38 PM.

#9

#10

Hi Speed grease is formulated for work in Hi-Speed bearings and usually has a higher than normal heat break down than regular. Also it lubricates better in these applications. Even wheel bearing for disk brake has a higher than normal heat range. Now regular hub/wheel bearing grease does not have a high enough heat range because of the heat from disk brake applications.

There is specifications listed on the back of the grease bottle. Ones like HS (hi-speed) EX (extreme pressure) MN (marine) MP (multi-purpose)

Check this out! Timken grease for their bearings which sould be the one your using or close to it.

http://www.alliedbearings.com/new_pr...en_grease.html

There are 2 basic greases you want in your arsenal:

1. Wheel Bearing Grease for disk brake applications. (Muti Grease) With specifications for your intended use.

2. Moly. Engine building and sealing and other work.

There is specifications listed on the back of the grease bottle. Ones like HS (hi-speed) EX (extreme pressure) MN (marine) MP (multi-purpose)

Check this out! Timken grease for their bearings which sould be the one your using or close to it.

http://www.alliedbearings.com/new_pr...en_grease.html

There are 2 basic greases you want in your arsenal:

1. Wheel Bearing Grease for disk brake applications. (Muti Grease) With specifications for your intended use.

2. Moly. Engine building and sealing and other work.

Do you think greasing it will cause it to fail?