How to remove C-clips with posi 9.25 ?

#1

#2

#3

#4

#5

i think its not a tru chrysler trac-lok. i think the whole differanal has to come out. and the casting needs the be separated by removing two bolts. it looks like the casting is split at 90 degree to the pin. iam guessing there is other bolt opp the one you can see in your pic. but removing and installing that stuff is not for every one. it requires some know how and skill. if it was mine i would pay to have it done. the tru chrysler trac-lok says that after a repair and fluid put in, to drive the truck in 6-7 large figure 8s. to get the fluid distributed in the plates just my idea. edit: 5 min later now that i think about it I THINK IAM ALL WET. maybe calling someone like randys rings. sorry about the goof up.

Last edited by moe7404; 04-05-2013 at 07:55 PM.

#6

After i jacked the truck up on stands, i could rotate the axles and carrier around to see the opening on one side. Undid the pin bolt and pulled the pin with a rachet strap to the bumper. Pushed the axles in far enough to pull the c-clips. Axles came out with ease. The carrier is held in at the bearings with adjusters inside the axle shaft. I made a tool to reach them from the end of the axles. It was just a large bolt pounded into a 3/4" square pipe 4' long. Hand strength is enough to unseat the adjusters. Tool worked great. Pulled the carrier out to get to the pinion which had a 1/4" of play in it. A 24" pipe wrench, 1/2" breaker bar, cheater bar, and 1 1/4" socket are all that i needed to get the nut off the pinion. Knocked the bearings off the pinion, and punched the races out of the housing. Pressed the new bearing onto the pinion with a press, tapped new races in. All other bearings were fine. Setting the pinion crush sleeve was pretty easy with the pipe wrench and breaker bar with a cheater on top of it. I crushed the sleave a 1/8th of a turn at a time until the bearings were just snug and no play in the pinion. Another 1/8th of a turn too much and you might cush the sleave too much and introduce play in it that way. The other axle bearings were fine. I adjusted the backlash with the homemade tool adjusting both carrier bearings in and out with each other until minimum backlash gap was established. I checked the splines for alignment with some white grease. Spun the carrier several times to notice the grease leaving pinion tracks dead center and vice versa. Put the axles back in with c-clips, pin and nut, and sealed the cover back on. 2 quarts of posi oil and runs smooth.

#7

Trending Topics

#8

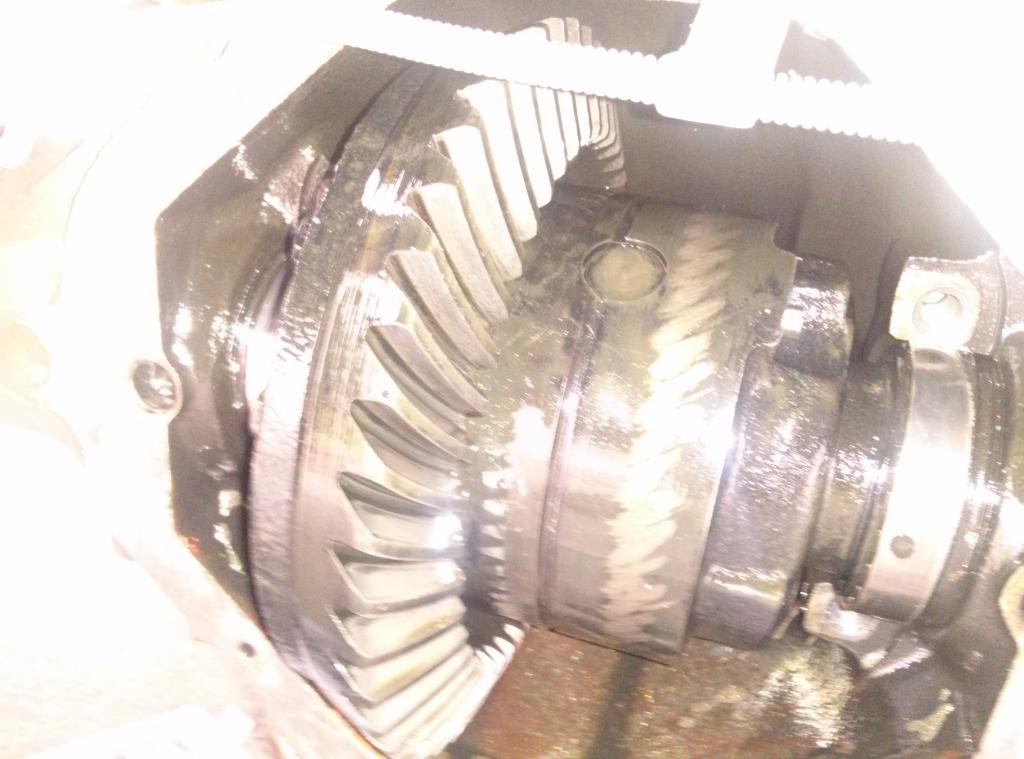

Thanks rambler reb and moe for chiming in. That download is some good information. I didnt have all the fancy tools to do it perfectly, but a little elbow grease goes a long way. I believe i prevented a future catastrophy by replacing the bearings and sleave on the pinion gear. If you notice in the picture above, the pinion was loose enough to just start rubbing on the carrier.