46RE Transmission growling (and so am I....)

#31

#33

Moral of the story....do not attempt transmission rebuild when tired, frustrated, or have your mind on something else....I knew better and just forgot to use the home made alignment shaft before I compressed the OD spring. Been focusing on a consulting project I have going and a job interview for Monday as well as trying to find a place to live in the Austin area (yes, I am 99% sure I'll be offered the job). And then dreading moving....car lot out back and all....

Last edited by gdstock; 10-16-2012 at 12:47 AM.

#34

So after being out of town for a job interview, started back on OD again this afternoon. Dropped it out and disassembled.

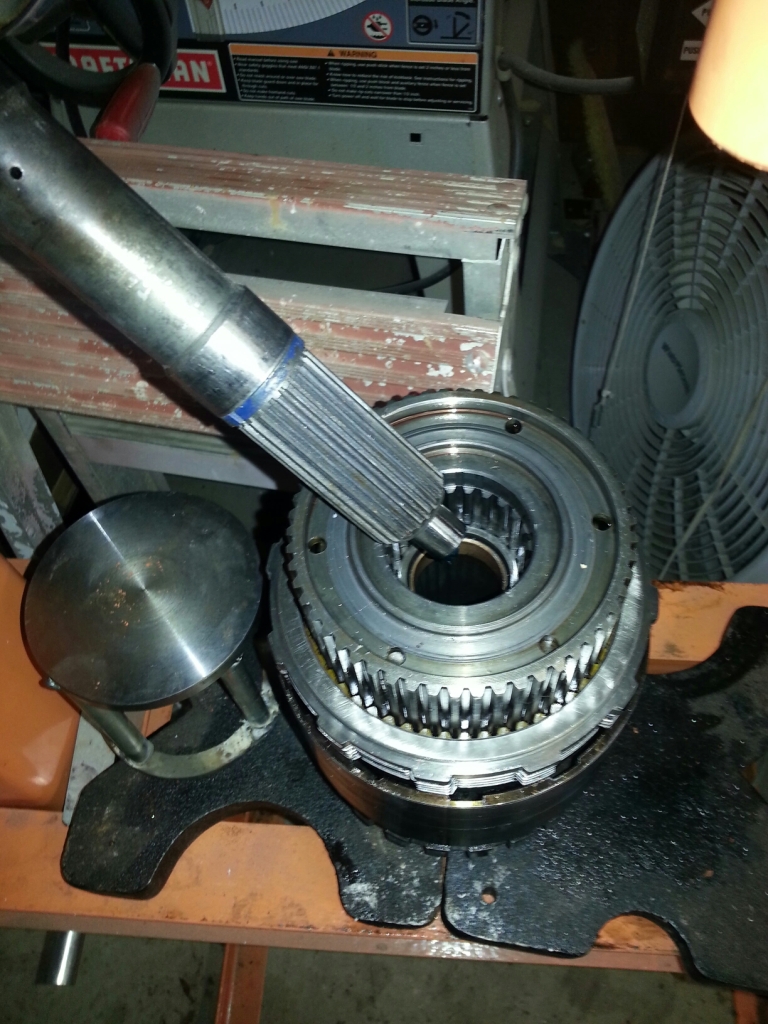

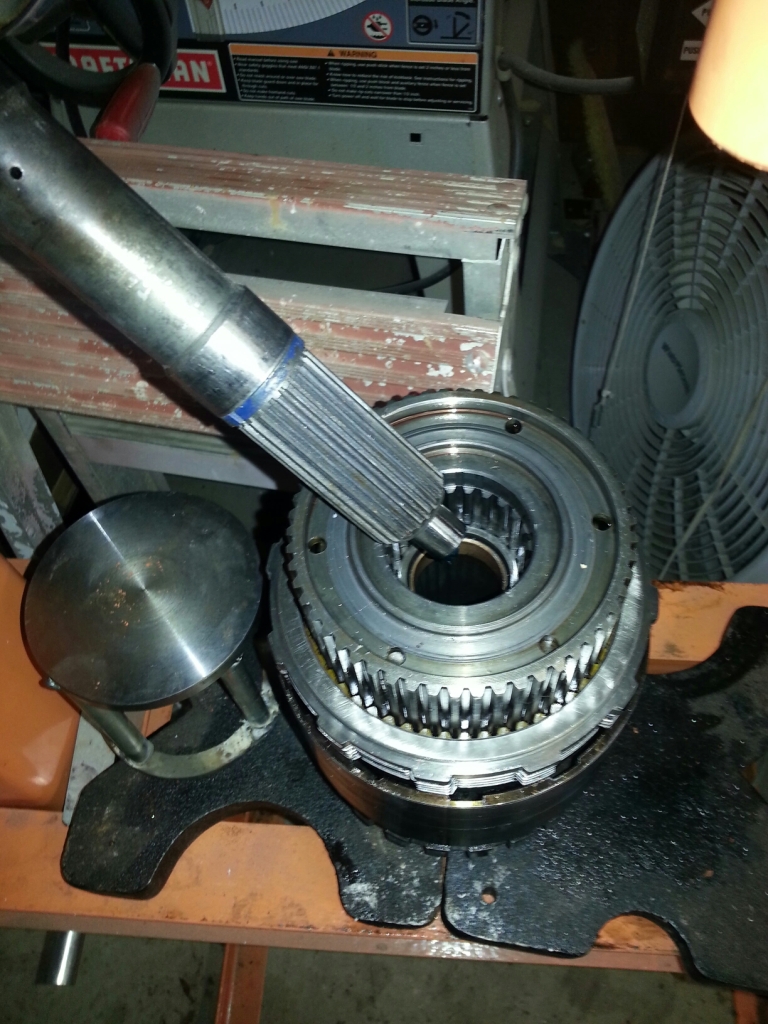

Intermediate shaft used for tooling. Bolt inserted fro ease of handling and can be removed during pressing operation, and reinstalled to remove shaft after unit pressed together.

Inserting tooling into OD:

Tooling dropped into place

Removing bolt:

Pressing OD:

Installing snap rings:

Reinserting bolt:

Removing Intermediate shaft tool:

OD unit is put back together and installed without problem…Forgot to pick up new internal filter when I got new remote filter and fluid the other day. Dropped the pan and it looked good inside with no debris…….Love it when I get lucky (if you can call this exercise luck……

On the job interview, I was in there for two hours. Think it went VERY well, so the likelihood of relocating to Austin is a possibility. Great news is they allow telecommuting two days a week….just NOT on Monday and Friday (groan…THAT would have been perfect!).

EDIT: UPDATE - Just test drove and trans is GOOD! (Just have to clean up garage...)

Intermediate shaft used for tooling. Bolt inserted fro ease of handling and can be removed during pressing operation, and reinstalled to remove shaft after unit pressed together.

Inserting tooling into OD:

Tooling dropped into place

Removing bolt:

Pressing OD:

Installing snap rings:

Reinserting bolt:

Removing Intermediate shaft tool:

OD unit is put back together and installed without problem…Forgot to pick up new internal filter when I got new remote filter and fluid the other day. Dropped the pan and it looked good inside with no debris…….Love it when I get lucky (if you can call this exercise luck……

On the job interview, I was in there for two hours. Think it went VERY well, so the likelihood of relocating to Austin is a possibility. Great news is they allow telecommuting two days a week….just NOT on Monday and Friday (groan…THAT would have been perfect!).

EDIT: UPDATE - Just test drove and trans is GOOD! (Just have to clean up garage...)

Last edited by gdstock; 10-16-2012 at 10:23 PM.

#35

#36

The outer diameter is 4" and inside is 3". I would make it 3 3/4" and 2 3/4" if I were doing it again. Top plate is 3/8' thick and bottom ring is 1/4". Had a local machine shop cut these from round stock. I used four pices of 7/16" rod at 5" long.

I picked up the intermediate shaft at no charge from an area tranny shop last year. If you do not cut it off, the press tooling has to be much taller....I can measure the length of this if you would like.

#38

I cut the intermediate shaft at 7 3/4" from the pilot. Worst case if you cannot find one cheap or free at a tranny shop, you can get it from www.wittrans.com part number U22674B, Shaft, A518/618 Intermediate, 1996-up, for $58.76. You can cut and leave a little longer, but I think any more than 10" would cause problem with pressing.

Last edited by gdstock; 10-22-2012 at 03:54 PM.