Icon forged Pistons 1997 Stroker 408

#1

#2

#5

Ive owned this truck since new and have never had a chance to really drive the new engine due to issues with tuning,20 plus tunes and it still wants to quit when I slow down.

So no i didn't break it in like I stole it. the engine at this point has only 2000 miles.

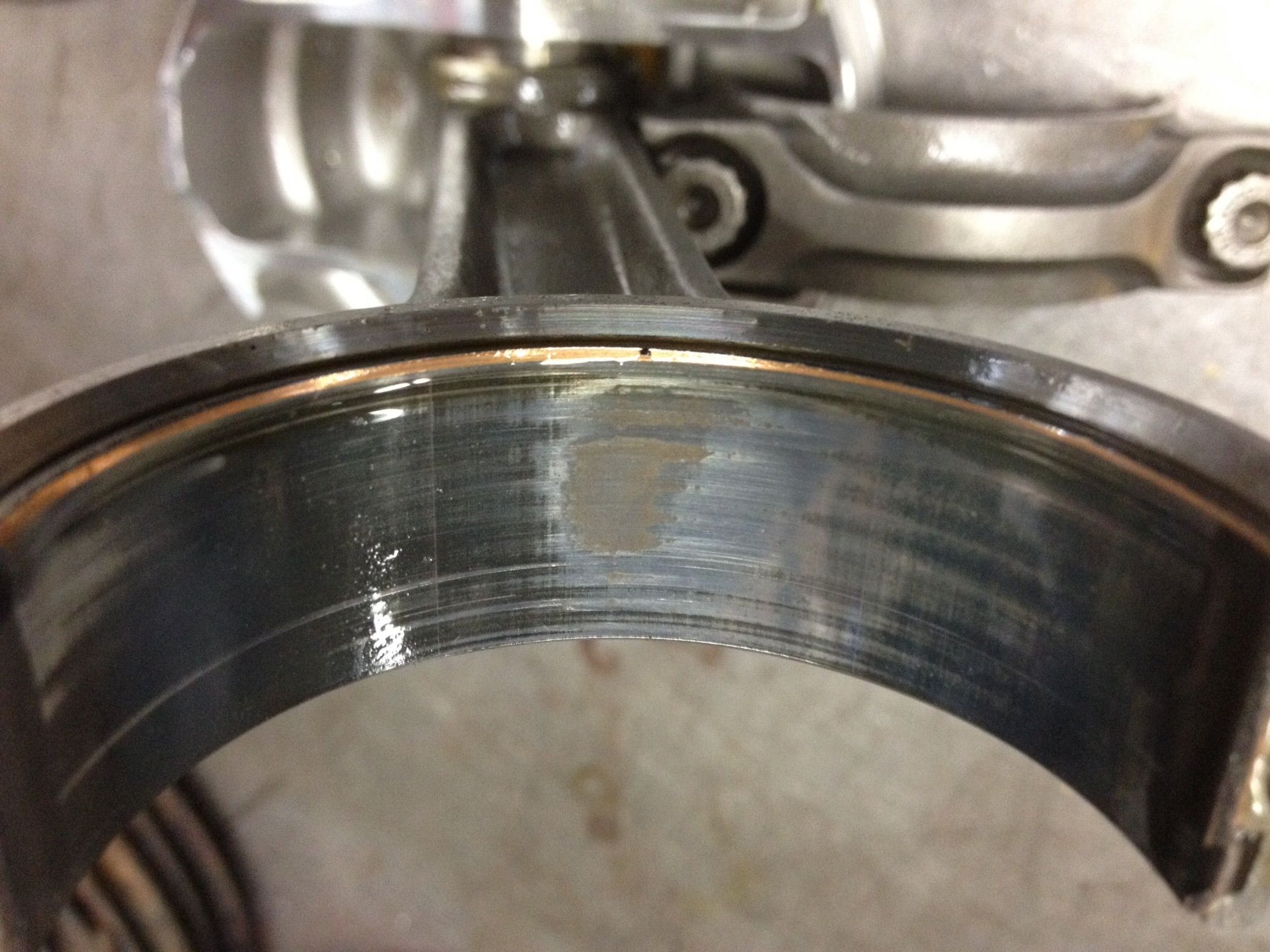

and the damage to the top of the rod bearing, from what I've been told, is caused by excessive down force on the piston, in a miss tuned ignition timing. Im just repeating what I've been told and hoping for other insightful views on this. this

So no i didn't break it in like I stole it. the engine at this point has only 2000 miles.

and the damage to the top of the rod bearing, from what I've been told, is caused by excessive down force on the piston, in a miss tuned ignition timing. Im just repeating what I've been told and hoping for other insightful views on this. this

#7

Trending Topics

#8

#10

HeyYou,

No idea why any of the bearings look as bad as they do. But this is why I am rebuilding the 408 instead of just dropping it into the Jeep. And I am going to follow Hughes Engines advice on how to install the cam bearings plus am going to drill out the oil passages.

Oiling system:

Small Blocks

Many times the mounting surface for the oil pump on the main cap is not level. Grind or mill it flat and do not use a gasket.

The oil passage from the pump does not line up with the passage in the main cap. Grind out this “stepover” area in the cap to

prevent a restriction here. The 360” is worse than the 340”. Restrict the oil flow through cam bearings #1 - #3 - #5 only by drilling a

new 1/8” oil hole in the cam bearing and then install bearing with this new, smaller hole aligned with the feed passage from the

mains. Run a straight ¼” reamer(our P/N 8350) completely through the main bearing oil feed passages #1 -#3 - #5 coming down

from the right hand lifter oil galley. Run a 9/32” reamer (P/N 8352) completely through the #2 - #4 main bearing feed passages. The

intersection of the large threaded oil passage, from the center of the oil filter to the main passage running to the rear of the block is

very rough in many cases. Smooth out all the rough spots and sharp edges in the intersection. Do not attempt to drill the passages

deeper. Water is close by.

If you are using our main stud girdle, it needs to clear all rotating parts by .030”.

A standard volume oil pump will supply enough oil to a 700 HP engine with the above modifications, a windage tray and 5

quarts of oil in the pan. We suggest our oil pan P/N 20710 for 340’s and P/N 20730 for 360’s; both use screen, P/N #6907. For more

ground clearance you can use pan #31590 on the 340 and 31595 on the 360. Position screen 5/16” to 3/8” from the bottom of the

pan. Oil pressure of 9# per 1000 RPM is adequate. Maximum pressure over 65 P.S.I. is not recommended.

This is from #9 Stroker Kit Instructions & Tips

Which opens up into this PDF And the info about oiling system is on page 2.

For the OP have you seen this info before?

No idea why any of the bearings look as bad as they do. But this is why I am rebuilding the 408 instead of just dropping it into the Jeep. And I am going to follow Hughes Engines advice on how to install the cam bearings plus am going to drill out the oil passages.

Oiling system:

Small Blocks

Many times the mounting surface for the oil pump on the main cap is not level. Grind or mill it flat and do not use a gasket.

The oil passage from the pump does not line up with the passage in the main cap. Grind out this “stepover” area in the cap to

prevent a restriction here. The 360” is worse than the 340”. Restrict the oil flow through cam bearings #1 - #3 - #5 only by drilling a

new 1/8” oil hole in the cam bearing and then install bearing with this new, smaller hole aligned with the feed passage from the

mains. Run a straight ¼” reamer(our P/N 8350) completely through the main bearing oil feed passages #1 -#3 - #5 coming down

from the right hand lifter oil galley. Run a 9/32” reamer (P/N 8352) completely through the #2 - #4 main bearing feed passages. The

intersection of the large threaded oil passage, from the center of the oil filter to the main passage running to the rear of the block is

very rough in many cases. Smooth out all the rough spots and sharp edges in the intersection. Do not attempt to drill the passages

deeper. Water is close by.

If you are using our main stud girdle, it needs to clear all rotating parts by .030”.

A standard volume oil pump will supply enough oil to a 700 HP engine with the above modifications, a windage tray and 5

quarts of oil in the pan. We suggest our oil pan P/N 20710 for 340’s and P/N 20730 for 360’s; both use screen, P/N #6907. For more

ground clearance you can use pan #31590 on the 340 and 31595 on the 360. Position screen 5/16” to 3/8” from the bottom of the

pan. Oil pressure of 9# per 1000 RPM is adequate. Maximum pressure over 65 P.S.I. is not recommended.

Which opens up into this PDF And the info about oiling system is on page 2.

For the OP have you seen this info before?