Valve Spring installation help

#1

Long time listener, first time caller. Generally I can search through old forum posts here to find the information I need but I am having trouble gaining a good enough understanding of this. I drive a 97, 5.9l with 170k miles.

I replaced my head gasket and was somehow talked into doing a valve job. I looked over reinstalling the springs and it seemed like it was doable. So I took the valve springs off. It's time now to put them back on. I have been told how to do it several different ways.

I apologize for my lack of proper terminology. My current understanding is- I need to turn the camshaft so that it is at TDC. I see that marking on the block. That enables me to reinstall a set of valve springs on the two piston faces that are currently all the way up, compressing the spring and dropping the two keepers into place. I then turn the camshaft clockwise 90 degrees (from 12 oclock to 3 oclock) to the next marking lining it up to the mark on the block. Install the next four springs on the two cylinders, rinse and repeat. Once I have all that done I start back at the TDC for the first two cyclinders to install the rocker arms, cycling through the same sequence with the camshaft to move each piston face to the top before installing the rocker arms.

That is what I understand so far. Am I understanding what TDC is correctly? That it is when the 'piston face' is all the way up? That doesn't have anything to do with the firing order does it? From studying the pistons move as I turned the camshaft while the heads were off, it looked like cyclinder 1 and cylinder 6 (per the firing order) are TDC when I set the camshaft in the beginning.

I do not need to measure any sort of gap? I have the instruction manual and it mentions a .432mm gap.

Am I right on how to install the rocker arms? Or is it unnecessary to go back through the timing sequence with the camshaft.

I have a little crappy air compressor. I don't know how big of one I would need to install these springs with that method.

Any help is a appreciated. I know I should have just sent the heads to a machine shop, but I wanted to give all this a try myself. I entirely regret it but I am determined to see it through now. Again sorry for my lack of proper terminology and lack of understanding. Thank you.

I replaced my head gasket and was somehow talked into doing a valve job. I looked over reinstalling the springs and it seemed like it was doable. So I took the valve springs off. It's time now to put them back on. I have been told how to do it several different ways.

I apologize for my lack of proper terminology. My current understanding is- I need to turn the camshaft so that it is at TDC. I see that marking on the block. That enables me to reinstall a set of valve springs on the two piston faces that are currently all the way up, compressing the spring and dropping the two keepers into place. I then turn the camshaft clockwise 90 degrees (from 12 oclock to 3 oclock) to the next marking lining it up to the mark on the block. Install the next four springs on the two cylinders, rinse and repeat. Once I have all that done I start back at the TDC for the first two cyclinders to install the rocker arms, cycling through the same sequence with the camshaft to move each piston face to the top before installing the rocker arms.

That is what I understand so far. Am I understanding what TDC is correctly? That it is when the 'piston face' is all the way up? That doesn't have anything to do with the firing order does it? From studying the pistons move as I turned the camshaft while the heads were off, it looked like cyclinder 1 and cylinder 6 (per the firing order) are TDC when I set the camshaft in the beginning.

I do not need to measure any sort of gap? I have the instruction manual and it mentions a .432mm gap.

Am I right on how to install the rocker arms? Or is it unnecessary to go back through the timing sequence with the camshaft.

I have a little crappy air compressor. I don't know how big of one I would need to install these springs with that method.

Any help is a appreciated. I know I should have just sent the heads to a machine shop, but I wanted to give all this a try myself. I entirely regret it but I am determined to see it through now. Again sorry for my lack of proper terminology and lack of understanding. Thank you.

Last edited by Ramchie; 03-24-2021 at 12:27 AM. Reason: cleaning up

#2

Long time listener, first time caller. Generally I can search through old forum posts here to find the information I need but I am having trouble gaining a good enough understanding of this. I drive a 97, 5.9l with 170k miles.

I replaced my head gasket and was somehow talked into doing a valve job. I looked over reinstalling the springs and it seemed like it was doable. So I took the valve springs off. It's time now to put them back on. I have been told how to do it several different ways.

I apologize for my lack of proper terminology. My current understanding is- I need to turn the camshaft so that it is at TDC. I see that marking on the block. That enables me to reinstall a set of valve springs on the two piston faces that are currently all the way up, compressing the spring and dropping the two keepers into place. I then turn the camshaft clockwise 90 degrees (from 12 oclock to 3 oclock) to the next marking lining it up to the mark on the block. Install the next four springs on the two cylinders, rinse and repeat. Once I have all that done I start back at the TDC for the first two cyclinders to install the rocker arms, cycling through the same sequence with the camshaft to move each piston face to the top before installing the rocker arms.

That is what I understand so far. Am I understanding what TDC is correctly? That it is when the 'piston face' is all the way up?

I do not need to measure any sort of gap? I have the instruction manual and it mentions a .432mm gap.

Am I right on how to install the rocker arms? Or is it unnecessary to go back through the timing sequence with the camshaft.

I have a little crappy air compressor. I don't know how big of one I would need to install these springs with that method.

Any help is a appreciated. I know I should have just sent the heads to a machine shop, but I wanted to give all this a try myself. I entirely regret it but I am determined to see it through now. Thank you.

I replaced my head gasket and was somehow talked into doing a valve job. I looked over reinstalling the springs and it seemed like it was doable. So I took the valve springs off. It's time now to put them back on. I have been told how to do it several different ways.

I apologize for my lack of proper terminology. My current understanding is- I need to turn the camshaft so that it is at TDC. I see that marking on the block. That enables me to reinstall a set of valve springs on the two piston faces that are currently all the way up, compressing the spring and dropping the two keepers into place. I then turn the camshaft clockwise 90 degrees (from 12 oclock to 3 oclock) to the next marking lining it up to the mark on the block. Install the next four springs on the two cylinders, rinse and repeat. Once I have all that done I start back at the TDC for the first two cyclinders to install the rocker arms, cycling through the same sequence with the camshaft to move each piston face to the top before installing the rocker arms.

That is what I understand so far. Am I understanding what TDC is correctly? That it is when the 'piston face' is all the way up?

I do not need to measure any sort of gap? I have the instruction manual and it mentions a .432mm gap.

Am I right on how to install the rocker arms? Or is it unnecessary to go back through the timing sequence with the camshaft.

I have a little crappy air compressor. I don't know how big of one I would need to install these springs with that method.

Any help is a appreciated. I know I should have just sent the heads to a machine shop, but I wanted to give all this a try myself. I entirely regret it but I am determined to see it through now. Thank you.

The following users liked this post:

Ramchie (03-24-2021)

#3

I guess the rocker arms I am not as worried about. I will definitely devote another round of research to the rocker arms before tackling them.

What I'm using to keep the valves from falling in the combustion chamber-

I was not sure I had to use something. The way it has been explained to me- the air compressor method and the spinning the camshaft are two different methods of achieving the same goal- to push the valve all the way up. I figured by rotating the camshaft I was lifting the valve with the piston?

Full disclosure, I got the bottom right spring on with the keepers. With the camshaft set to TDC. Did I just get lucky?

What I'm using to keep the valves from falling in the combustion chamber-

I was not sure I had to use something. The way it has been explained to me- the air compressor method and the spinning the camshaft are two different methods of achieving the same goal- to push the valve all the way up. I figured by rotating the camshaft I was lifting the valve with the piston?

Full disclosure, I got the bottom right spring on with the keepers. With the camshaft set to TDC. Did I just get lucky?

Last edited by Ramchie; 03-24-2021 at 12:47 AM.

#5

If you try and push the valves up with the piston, you will likely bend them. Even if it works, it won't push the valve up far enough to be able to get the springs on there..... The trick is to do it one cylinder at a time. Turn the crankshaft so the cylinder you are working on is at top dead center on the compression stroke, (both valves closed.) apply air pressure to the cylinder to keep the valves closed, pull the springs, change the seals, then reinstall the springs. (or, install new ones.....) It's tedious, but, a relatively easy job.

#7

If you try and push the valves up with the piston, you will likely bend them. Even if it works, it won't push the valve up far enough to be able to get the springs on there..... The trick is to do it one cylinder at a time. Turn the crankshaft so the cylinder you are working on is at top dead center on the compression stroke, (both valves closed.) apply air pressure to the cylinder to keep the valves closed, pull the springs, change the seals, then reinstall the springs. (or, install new ones.....) It's tedious, but, a relatively easy job.

Is the measuring only done of you install the springs without the heads ones? Just trying to wrap my head around the process

thank you guys for your help. Your posts from years ago have helped me out in the past. Saved me thousands of dollars.

Trending Topics

#8

I guess I just got lucky with the first one? Or potentially bent the valve but let's not go there. I'm out now to get an attachment for my air hose to go in the spark plug.

Is the measuring only done of you install the springs without the heads ones? Just trying to wrap my head around the process

thank you guys for your help. Your posts from years ago have helped me out in the past. Saved me thousands of dollars.

Is the measuring only done of you install the springs without the heads ones? Just trying to wrap my head around the process

thank you guys for your help. Your posts from years ago have helped me out in the past. Saved me thousands of dollars.

#9

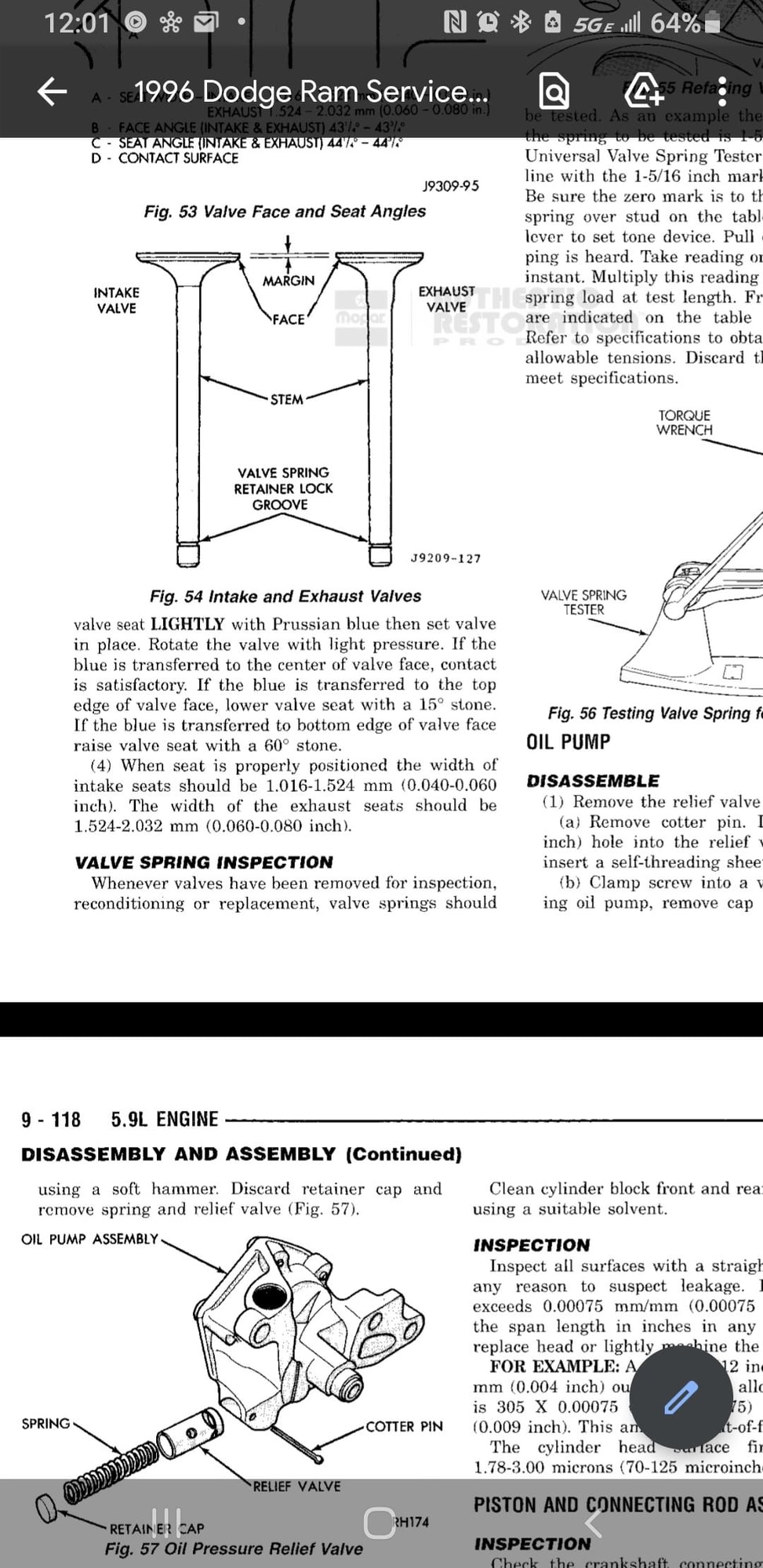

There is stuff in the manual about putting a spacer at the bottom of the spring and measuring the height of the springs. On the road now I can put a picture up here in a bit of the manual

Wow these spark plug air attachments are hard to find. Probably gonna use the rope method

Wow these spark plug air attachments are hard to find. Probably gonna use the rope method

Last edited by Ramchie; 03-24-2021 at 12:18 PM.

#10

This spring took about a minute to get on as compared to the hour it took with no rope. Thank you.

Should I remove that first one I put on without rope and check how the stem feels going up and down? Installed it presumably against the piston face. But I'm pretty sure I was able to crank the spring down far enough to get it on without moving the valve..

I think I'm just confusing myself with the heithese of the stem. Theres nothing I could do to fix the height, I suppose I would just be checking to make sure current spring set up is still operational and not stretched

the piston never goes right up the head/valves there is also a gap.

the piston never goes right up the head/valves there is also a gap.