Still fighting Alternator fitment woes, Input appreciated

#1

Been most-days driving the truck The past couple weeks and noticed my alternator belt tension started going south and needing frequent adjustment. Shrugged it off to ďehh itís old and getting broken back inĒ, adjusted and moved on with my day. Noticed yesterday while replacing a leaking steering hose, and trans cooler lines that were on their last leg the alternator bearing made much more noise then had when previously parked. And belts slipped on cold start. So leak checked what I needed to check. Started looking at alternator stuff and realized when full tightened was sitting cocked.

86 D150 100 amp alt, with AC and AUX Air Pump.

my thoughts are this.

a. 6 years parked was enough to warp the harmonic balancer, so maybe it was enough to fatigue the memory of the steel and I need to bend it back.

b. The alternator being new, could have the bushing/sleeve for the bolt be misaligned/bad out-of-box. (I did buy the cheapest one on the shelf )

)

c. I could have simply kept too much tension on the belts and now that the belts are shot, me having to have it close to the end of its adjustment range under tension is simply the culprit for the misalignment. Say due to length between pivot points.

if anyone else has experienced a similar situation, or even has a spit-ball idea to check or try Iím in to try it out. Truck is down for four more days anyway while Iím cleaning and inspecting other stuff.

86 D150 100 amp alt, with AC and AUX Air Pump.

my thoughts are this.

a. 6 years parked was enough to warp the harmonic balancer, so maybe it was enough to fatigue the memory of the steel and I need to bend it back.

b. The alternator being new, could have the bushing/sleeve for the bolt be misaligned/bad out-of-box. (I did buy the cheapest one on the shelf

)

)c. I could have simply kept too much tension on the belts and now that the belts are shot, me having to have it close to the end of its adjustment range under tension is simply the culprit for the misalignment. Say due to length between pivot points.

if anyone else has experienced a similar situation, or even has a spit-ball idea to check or try Iím in to try it out. Truck is down for four more days anyway while Iím cleaning and inspecting other stuff.

Last edited by Polye86_RoyalSE; 08-26-2020 at 03:12 PM.

#2

#3

itís not the pulley, itís the whole alternator. Hang on, Iíll go to the garage to add a picture.

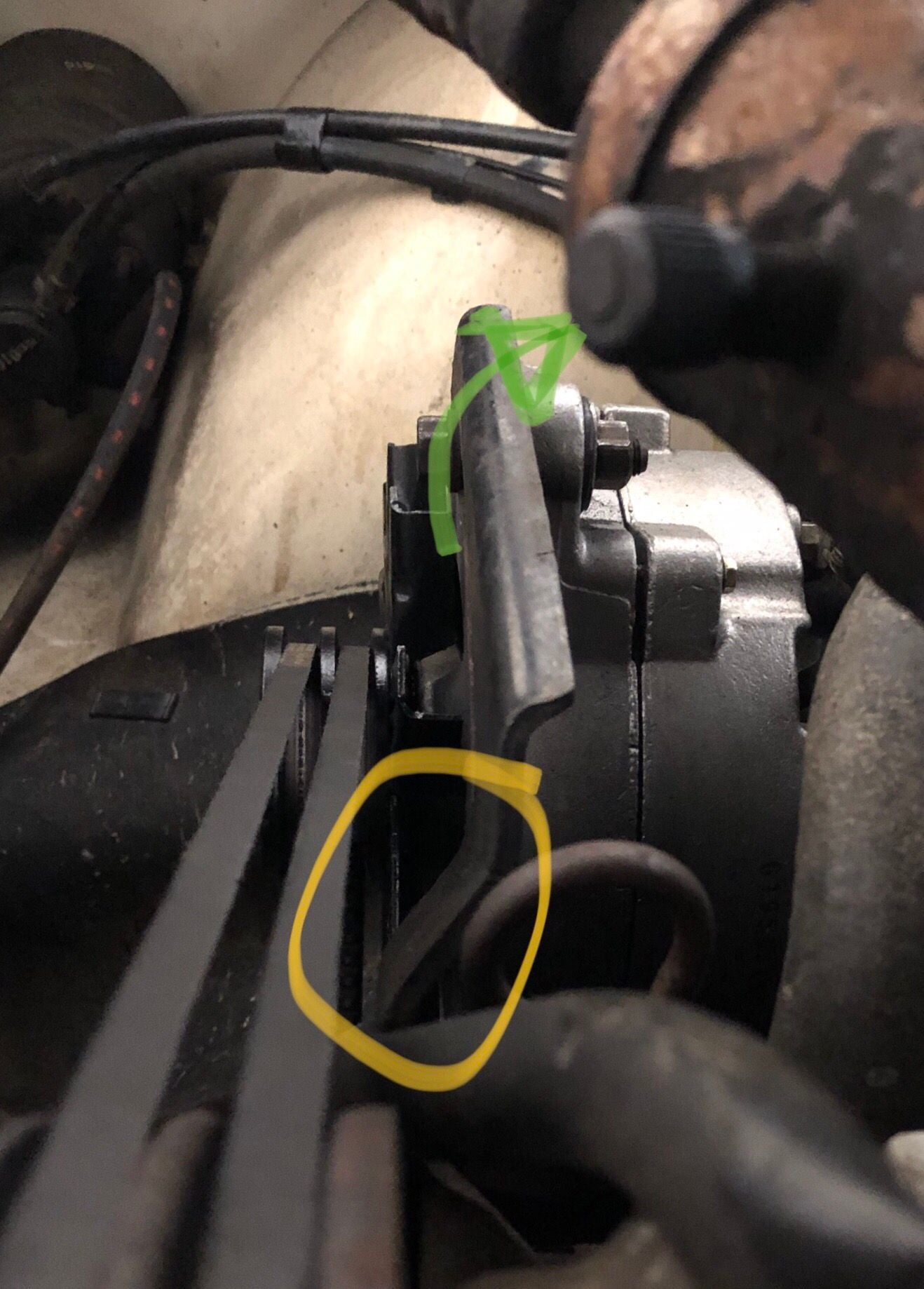

Hard to tell, but the belts are pulled more towards the front face of the pulley.

This is current tension (yes Iím putting on new belts, which is part of why Iím sorting this out) the circled bolt print is where these belts started about 2800 miles ago.

Where the upper bolt passes through: when tightened the alternator tweaks the unused hole towards the front of the truck.

since belts are $40 a pair Iíd like to hear some input before I naw through the next pair. Also if anyone knows any ideas, tossíem my way.

Last edited by Polye86_RoyalSE; 08-26-2020 at 09:44 PM.

#4

#6

Moparite - Any speculations as to what my have been the culprit? Figured it may be a known ďgremlinĒ for trucks that sat undriven for as much time as this one has. (Iíve driven it more in a month, then itís yearly average, and Iíve seen plenty of signs of ďehh itíll be fine I donít drive it muchĒ maintenance /lack of)

I guess I could take some measurements to see how much I need to bend it, and could use some heat with a cheater bar/pipe over the end 🤔

Last edited by Polye86_RoyalSE; 08-27-2020 at 09:03 AM.

#7

The area in yellow is the area where I feel the warp occurred and can be corrected the easiest. Green is the direction of applied force.

With the angle of the bends existent in the bracket, I suspect if I bend back/down that should bring it back in line.

Figured Iíd give it a go myself, and if I need to toss new belts on and soft-drive it to bigger hotter tools I can.

thanks gents.

Trending Topics

#8

check the area of the bottom thru bolt... and no, harmonic balancers don't "warp" I doubt the alternator itself is the cause, they reused an existing housing, they dont redrill anything.

a crooked bearing within the housing would cause a bind when the alt spins and possibly crack the case, unlikely. It's 99% within the brackets.... and I wouldnt worry about the belt being tensioned in a different spot within the slot, they arent the same belts that were on there to begin with, though if something in the brackets was bent and/or cracked that would help explain having to keep adjusting that often though it isnt uncommon to have to readjust some as belts stretch and wear in. Concentrate on the brackets/ what holes were used to mount (and if it were mine it would no longer have an air pump, story for later)

a crooked bearing within the housing would cause a bind when the alt spins and possibly crack the case, unlikely. It's 99% within the brackets.... and I wouldnt worry about the belt being tensioned in a different spot within the slot, they arent the same belts that were on there to begin with, though if something in the brackets was bent and/or cracked that would help explain having to keep adjusting that often though it isnt uncommon to have to readjust some as belts stretch and wear in. Concentrate on the brackets/ what holes were used to mount (and if it were mine it would no longer have an air pump, story for later)

#9

#10

check the area of the bottom thru bolt... and no, harmonic balancers don't "warp" I doubt the alternator itself is the cause, they reused an existing housing, they dont redrill anything.

a crooked bearing within the housing would cause a bind when the alt spins and possibly crack the case, unlikely. It's 99% within the brackets.... and I wouldnt worry about the belt being tensioned in a different spot within the slot, they arent the same belts that were on there to begin with, though if something in the brackets was bent and/or cracked that would help explain having to keep adjusting that often though it isnt uncommon to have to readjust some as belts stretch and wear in. Concentrate on the brackets/ what holes were used to mount (and if it were mine it would no longer have an air pump, story for later)

a crooked bearing within the housing would cause a bind when the alt spins and possibly crack the case, unlikely. It's 99% within the brackets.... and I wouldnt worry about the belt being tensioned in a different spot within the slot, they arent the same belts that were on there to begin with, though if something in the brackets was bent and/or cracked that would help explain having to keep adjusting that often though it isnt uncommon to have to readjust some as belts stretch and wear in. Concentrate on the brackets/ what holes were used to mount (and if it were mine it would no longer have an air pump, story for later)

Is that long mounting bolt tight? When you had the alternator off was the bracket still bent like that? When you tighten the belts does the bracket bend? I have seen some bracket's get stressed and not hold the alternator in place without bending. Also seen stress cracks.

Thanks again for all the help everyone. Itís really appreciated considering how convoluted finding some of these specifications are on such an old vehicle.