1997 Ram 5.9 Rebuild power issues

#31

#32

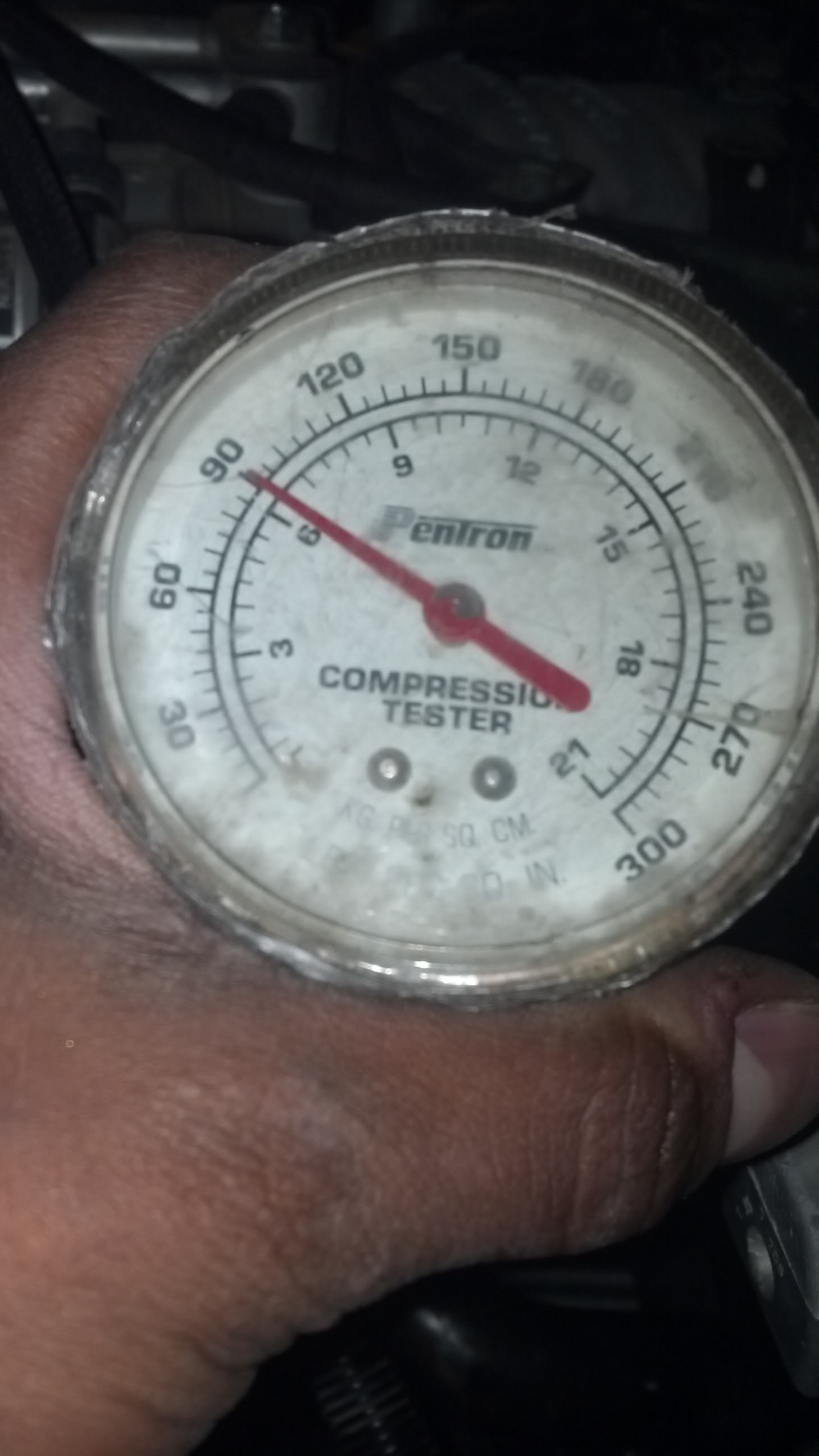

This is a fresh rebuild, and you are only getting 95PSI on most cylinders, and 65 on three of them? Right there is your problem. If you are below 100PSI on a new motor..... something in the reassembly didn't go quite right.

Was the block bored? Checked for taper? Roundness?

Was the block bored? Checked for taper? Roundness?

#33

Re do the test this way.

Remove all the spark plugs

Relax all the rocker arms, this will eliminate possible pushrod length issues/bad lifter's and let the valves close 100%, well it should.

Next run your tests again.

If the numbers improve then there is a timing, pushrod length, possible cam or lifter issue.

If I had comp numbers like that on a fresh rebuild I would not be happy at all. They should be high not low. If it is found to be the builders fault I would bill him for R&R time for sure.

Remove all the spark plugs

Relax all the rocker arms, this will eliminate possible pushrod length issues/bad lifter's and let the valves close 100%, well it should.

Next run your tests again.

If the numbers improve then there is a timing, pushrod length, possible cam or lifter issue.

If I had comp numbers like that on a fresh rebuild I would not be happy at all. They should be high not low. If it is found to be the builders fault I would bill him for R&R time for sure.

Last edited by merc225hp; 05-07-2013 at 01:04 PM.

#34

Re do the test this way.

Remove all the spark plugs

Relax all the rocker arms, this will eliminate possible pushrod length issues/bad lifter's and let the valves close 100%, well it should.

Next run your tests again.

If the numbers improve then there is a timing, pushrod length, possible cam or lifter issue.

If I had comp numbers like that on a fresh rebuild I would not be happy at all. They should be high not low. If it is found to be the builders fault I would bill him for R&R time for sure.

Remove all the spark plugs

Relax all the rocker arms, this will eliminate possible pushrod length issues/bad lifter's and let the valves close 100%, well it should.

Next run your tests again.

If the numbers improve then there is a timing, pushrod length, possible cam or lifter issue.

If I had comp numbers like that on a fresh rebuild I would not be happy at all. They should be high not low. If it is found to be the builders fault I would bill him for R&R time for sure.

As for pushrod, cam issues, we only put in a mild .480 cam, and i got pushrods and springs from hi-potek. The builder did tell me he had to grind down the heads slightly to seat the valves, so maybe that is the issue.

#37

+1 To short, go back to stock length but in a hardened rod. I would still like to see a comp test done with the rockers relaxed.

#38

It's got to be somewhere in the heads.